Home › Forum › Ask A Member › No spark

- This topic has 27 replies, 6 voices, and was last updated 5 months, 1 week ago by

Mallett.

-

AuthorPosts

-

August 30, 2025 at 1:48 pm #299452

why not just start with a good wash down with a strong spray of automotive disc cleaner …or carb cleaner followed with a strong air compressor blow job.

Wipe the points clean & set the points at .020 (the usual spread) on the high spot of the cam lobe. at the very least perfect or not do test the condensers with a analog VOM for a kick on the needle, opens or shorts. Some digital meters will test uf value but it is not a 100% guaranty. Condensers need to be test at high voltages for leaks !! see diag for a very basic test cct.

better yet build yourself a Mohat test box which will boost the commercial AC peaks up to about 270+ dc volts !

Joining AOMCI has priviledges 🙂

1 user thanked author for this post.

August 31, 2025 at 8:50 am #299478So I pulled the mag off went through it again set the points .020. Did I mess up the timing by pulling the mag off to clean under it? I couldn’t get it to fire up. Back in the shop this morning trying to get her going.

August 31, 2025 at 9:27 am #299480

Video on timing an outboard motor – https://youtu.be/Nz_o0J70Pas?si=0nKWDTm44MLDZMlt

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

2 users thanked author for this post.

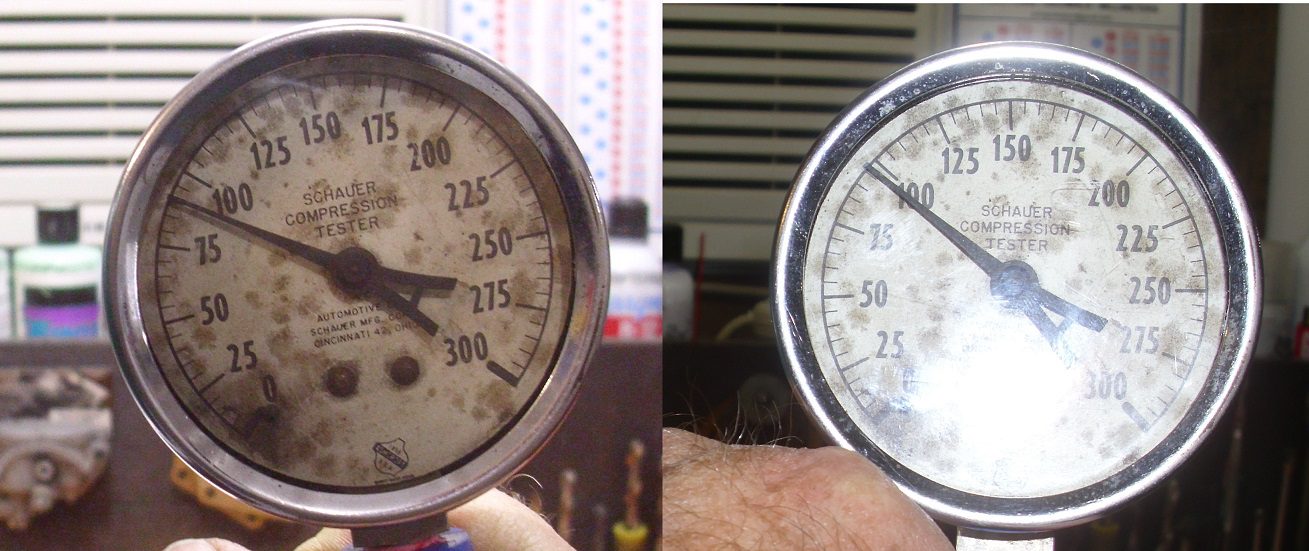

August 31, 2025 at 10:38 am #299481Okay then, from the video I see I didn’t mess up the timing. Am I getting this right? Should there be some lubricant on the mounting surface of the motor and mag? Moving to the next thing the compression is just under 90lbsqin is that enough?

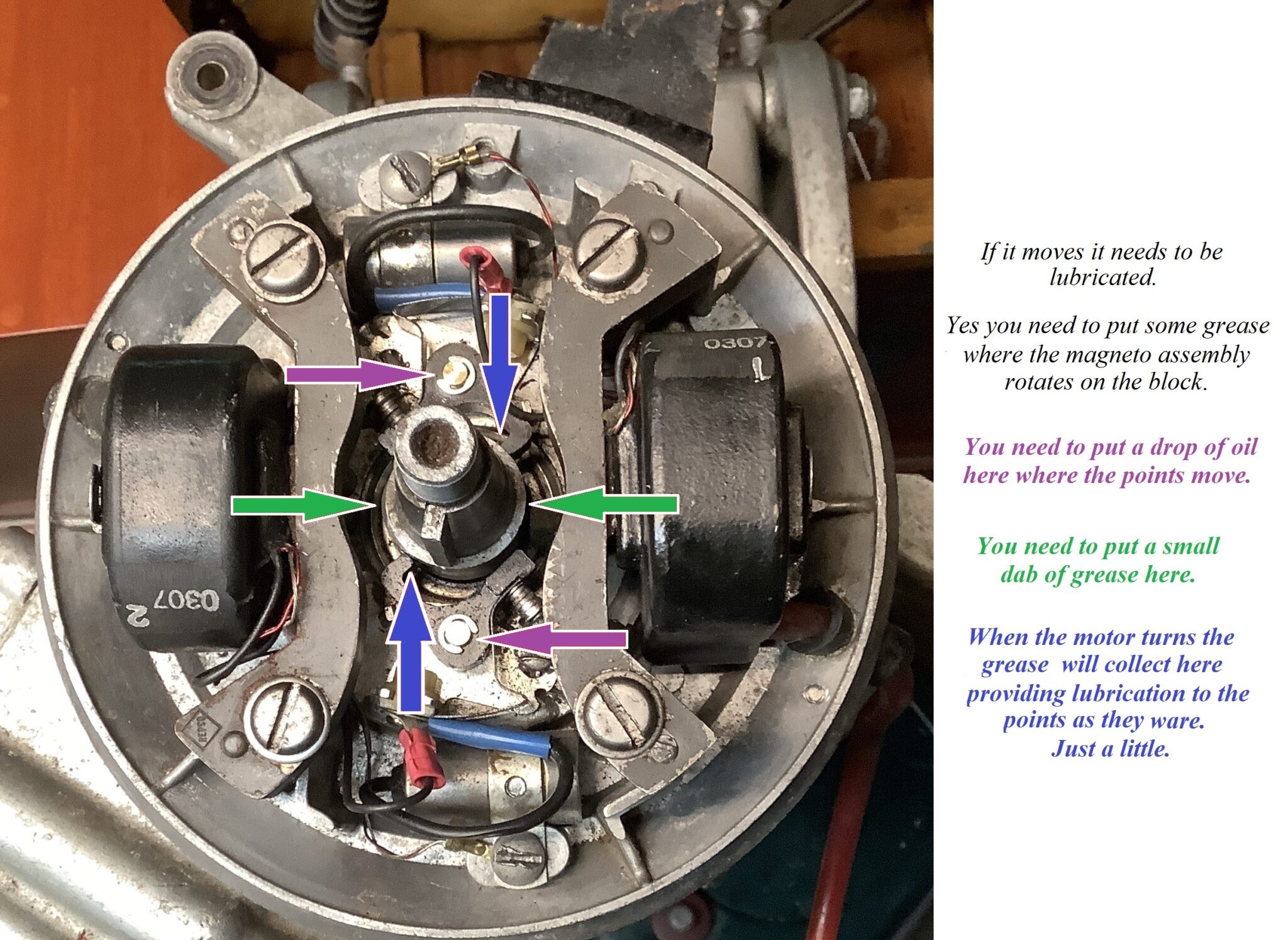

Happy SundayAugust 31, 2025 at 10:50 am #299482Do you have a VOM? They are very useful when evaluating ignition components. Put just a small amount of grease where the mag plate rotates on the block.

When testing Compression it is more important (or meaningful) to have equal (within 10% or so) numbers on both cylinders. Gauges vary as well. I wouldn’t worry about the compression at this time. You will likely see the numbers go up a bit after the engine is run for a while.

So; you have good spark on both plugs now?

1 user thanked author for this post.

August 31, 2025 at 11:15 am #299483Negative on the vom. Trying to get one from a buddy. I feel like the dog chasing the car what do I do with it when I get it?

Yeah seems to have good bright light in the tester on both cylinders.

The compression was pretty equal in each one too, so yeah not to worry now.

August 31, 2025 at 4:24 pm #299506try utubes on use of VOM… basic electricity tutorials are plenty

Joining AOMCI has priviledges 🙂

1 user thanked author for this post.

August 31, 2025 at 9:58 pm #299507One thing to look at is fuel flow from the tank. The tank has a fuel filter inside the tanl.Please remove the big chrome nut under the tank. That will expose the filter, stud, nut & holding washers. See if everythingis in place, Ive seen them in all conditions. If there is no filter go to a chain saw shop & buy a in line fuel filter there. Remember that small of a carb has tiny fuel passages & require a good filter.

While at the lake my KG7 was acting up. I removed & installed the low speed jet & a tiny piece of something came out. It ran so much better just with that flush. And as Tubs said check all wires for clearances too.

August 31, 2025 at 11:24 pm #299514

Okay then, from the video I see I didn’t mess up the timing. Am I getting this right? Should there be some lubricant on the mounting surface of the motor and mag? Moving to the next thing the compression is just under 90lbsqin is that enough?

Happy SundayCompression in this motor is 90 & 95 lbs. Video link – https://youtu.be/sm4M0xnXm-I?si=HmU6WPXw6-c84noa

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

September 1, 2025 at 10:10 am #299519

Okay then, from the video I see I didn’t mess up the timing. Am I getting this right? Should there be some lubricant on the mounting surface of the motor and mag? Moving to the next thing the compression is just under 90lbsqin is that enough?

Happy SundayA "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

-

AuthorPosts

- You must be logged in to reply to this topic.