Home › Forum › Ask A Member › Old condensers wanted for magazine article

- This topic has 10 replies, 8 voices, and was last updated 4 years, 4 months ago by

Buccaneer.

Buccaneer.

-

AuthorPosts

-

March 22, 2020 at 7:34 pm #198042

I’m doing a study of condensers, for an article for the Antique Outboarder. Most newer condensers are 0.22uF (or close to it.) But, REALLY OLD condensers on 1910s and 1920s motors were much larger. (1 to 2 uF, perhaps?) I need a few of these really old condensers, to measure and do failure analysis on. ANY CONDITION WILL DO. (Part of the article I’m writing will be to show how to “hollow out” a really old condenser, and hide a modern polystyrene capacitor inside of it. This will restore the condenser to a functioning state, and give it about a 50 year lifetime at the same time.)

If you have any of those really old, BIG condensers that you can donate to this analysis / study, please let me know. Thanks!

–Bill Mohat / WRC Chapter

***********************************************************************

Bill Mohat MS/CIS, BSEET, CCNA"You can avoid reality, but you cannot avoid the consequences of avoiding reality." --Ayn Rand **********************************************

March 23, 2020 at 11:55 am #198121Sounds like a great article

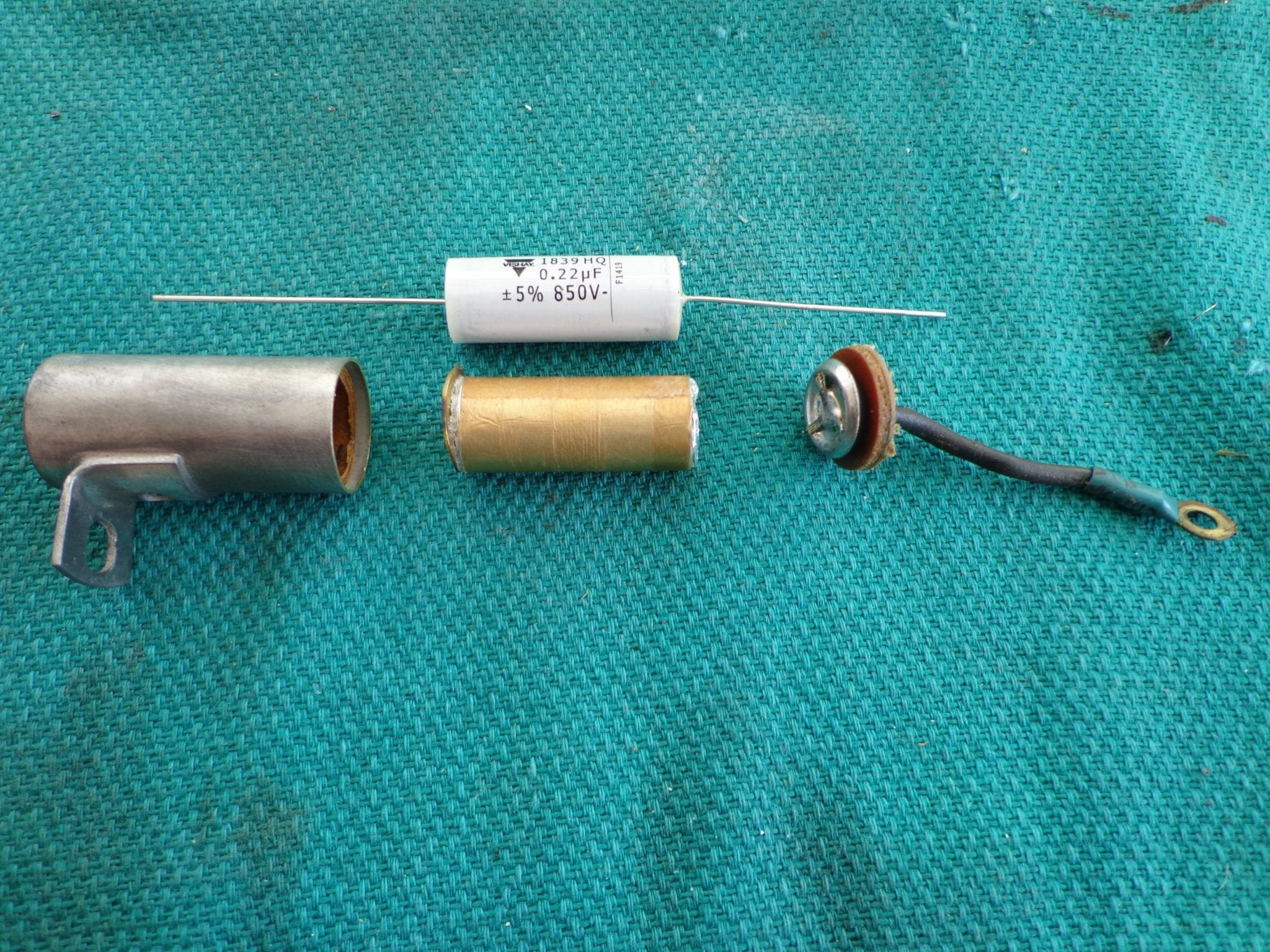

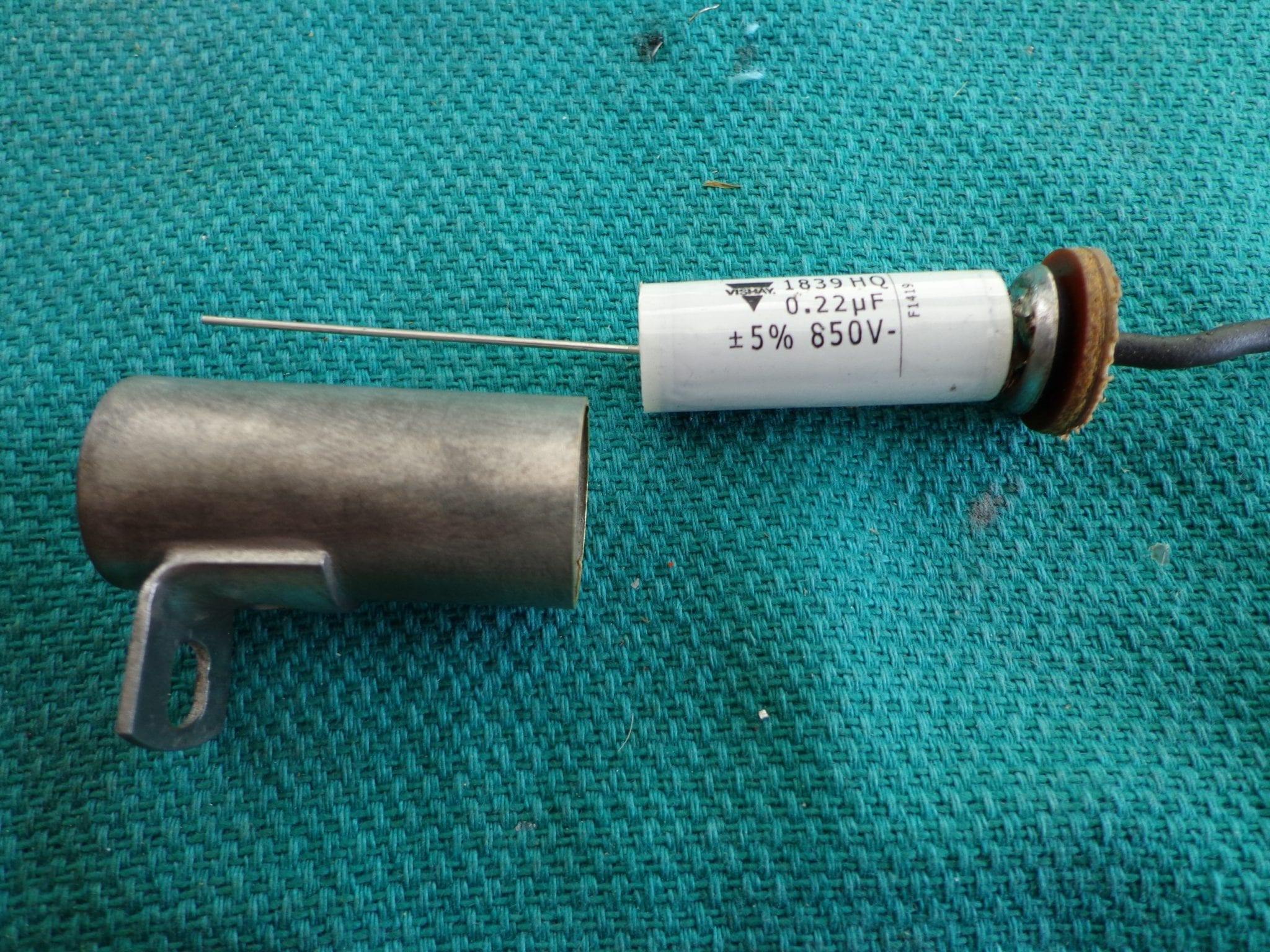

Wish I had some to donate.March 23, 2020 at 1:15 pm #198127No old and big caps here either but I have stuffed the taller 50’s – 60’s OMC condensers with a modern replacement capacitor. After removing the original stuffing, the end gets drilled so the terminal of the new cap can pass thru and get soldered on to the end of the can. The other terminal gets soldered onto the end with the lead and then the can gets filled with clear epoxy and clamped together overnight. Once the epoxy has set, the cap is now ready for use. This is just one way to do it and I’m sure there are more.

March 23, 2020 at 1:58 pm #198136I’ve done this with the stand-up WICO condensers. I cut the bottom open with a lathe and a very sharp tool, install the discrete component, and resolder the case shut. It was really the only option for those WICO condensers, since the screw terminal on top is integral to the system. The brass cans are VERY soft, so my success rate was about 80% over a dozen or so. I’ve rarely found one of these original condensers to be good, they all are very leaky. You’ll get one or two good sparks out of it at slow speed, which fools you into thinking they are OK. But when leak tested at any voltage above 20 or so, they fail.

T

-

This reply was modified 5 years, 3 months ago by

Tom.

Tom.

March 24, 2020 at 11:32 am #198196I’ve done this with the stand-up WICO condensers. I cut the bottom open with a lathe and a very sharp tool, install the discrete component, and resolder the case shut. It was really the only option for those WICO condensers, since the screw terminal on top is integral to the system. The brass cans are VERY soft, so my success rate was about 80% over a dozen or so. I’ve rarely found one of these original condensers to be good, they all are very leaky. You’ll get one or two good sparks out of it at slow speed, which fools you into thinking they are OK. But when leak tested at any voltage above 20 or so, they fail.

T

-

This reply was modified 5 years, 3 months ago by

Tom.

Tom.

Tom I would very much like to see pictures of the process; should you have any. And; certainly a picture of the finished project! I’ve been wondering what solution there is to remedy those WICO leakers…..

Chuck

March 28, 2020 at 11:23 am #198661To Mumbles, Tom and Seakaye12:

I usually drill out the top of a condenser, and pull out the guts. I then drill one tiny hole (1/16″) or so in the center of the bottom of the case. I insert the new capacitor, and then bend the lead over sideways and solder it down. ( The silver colored condensers are usually mild steel, coated in solder -matte tin, usually- so it’s easy to solder to.) I then point the can up. and solder the old stranded wire condenser lead to the top of the cap, and then seal it with JB Weld epoxy. These things look EXACTLY like a “stock” unit, but will last FAR longer than the original condenser.

But….. what I’m trying to locate are some of the very old (1910s, 1920s) condensers off of very early Johnson, Caille (etc) outboards…..the ones

that are about 2 to 5 times larger than your standard condenser. I’d like to measure their value (in microfarads), then “rebuild” a few of them to “better than factory OEM equipment” standards.Does ANYONE have any really old, BIG condensers (dead!) they can donate for this effort? Thanks!

–Bill***********************************************************************

Bill Mohat MS/CIS, BSEET, CCNA"You can avoid reality, but you cannot avoid the consequences of avoiding reality." --Ayn Rand **********************************************

February 22, 2021 at 10:48 pm #232021Going to resurrect an old thread. Working on my WB3 which has a WICO ignition system. The coil tests good but the condenser is trash as I understand is common. Planning on installing (or trying to install) a new cap in the case. Anyone done this on a condenser that has the screw instead of a wire lead?

KirkFebruary 22, 2021 at 11:07 pm #232024I’ve rigged a cap in that type of condenser by drilling a small hole next to the threaded

post, then running the cap wire thru the hole and wrap it around the threaded post,

under the nut.Prepare to be boarded!

February 22, 2021 at 11:43 pm #232035Hey Buc, I thought I remembered seeing a reconditioned condenser but couldn’t how it was done. In looking at the condenser, it looks like the top is soldered on. Were you able to melt the solder and get it apart?

KirkFebruary 23, 2021 at 12:58 am #232038I wonder of a Briggs Stratton conensor would work I THINK the old ones were threaded.

-

This reply was modified 5 years, 3 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.