Home › Forum › Ask A Member › OMC serial number

- This topic has 7 replies, 4 voices, and was last updated 3 years, 6 months ago by

fleetwin.

-

AuthorPosts

-

December 24, 2021 at 9:23 pm #251706

I recently bought an OMC power head. I have no model number. The serial number is J3108529 Anybody have an idea what year it is? Three millionth motor range so maybe mid seventy’s?

Wadaya think?dale

Brutey is in the hand of the guy holding the beer!!

December 29, 2021 at 9:54 am #251881can you post a picture of the powerhead??

December 29, 2021 at 7:10 pm #251931can you post a picture of the powerhead??

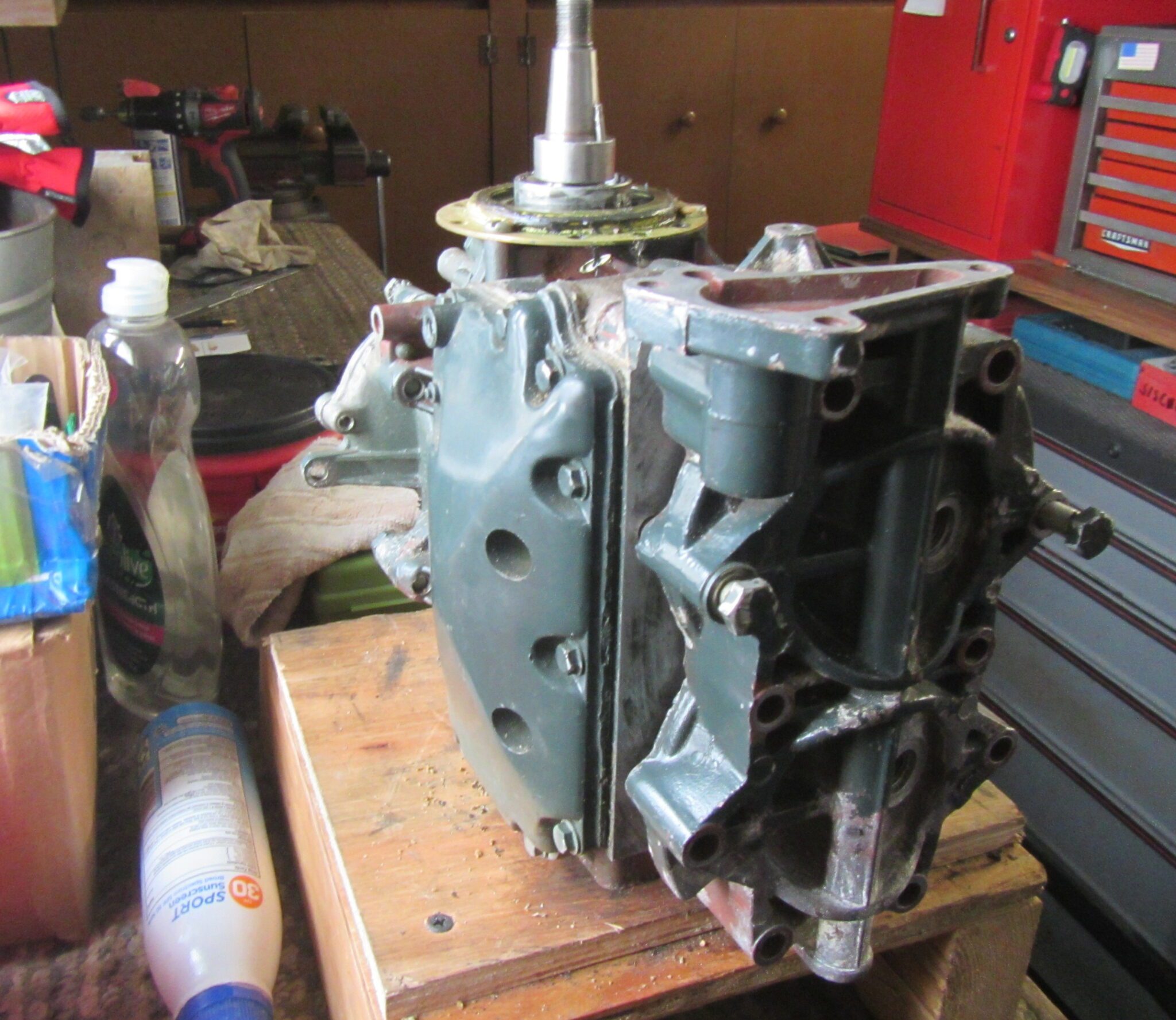

Sure can! I am the kinda guy that likes to know how things work. I am pretty sure it’s an 18 or 20hp. I was trying to understand the oiling system on this OMC powerhead. The gas/oil mix that gets pumped from the lower main bearing to the top bearing. I originally thought the drilling passages going to the reed block were blocked but they are not there on this engine. The older engines, I am sure you know, use the crankcase pressure to send lube through the motor. I might have to split the cases on this PH, to find out I guess! There is a line that goes from the transfer cover to the carb side of the reed valve that goes nowhere. The usual hose goes from the lower to the upper main bearing is there.

life is a puzzle! Outboards too!

Thanks dale

December 30, 2021 at 9:25 am #251954Dale, Most of this info was from Frank Robb’s great explanation in previous posts of this drainage setup.

From around 1950 thru 1967 the crankcase puddle drains led to a channel and passage in the front of the casting and were dumped into the exhaust housing and lake.

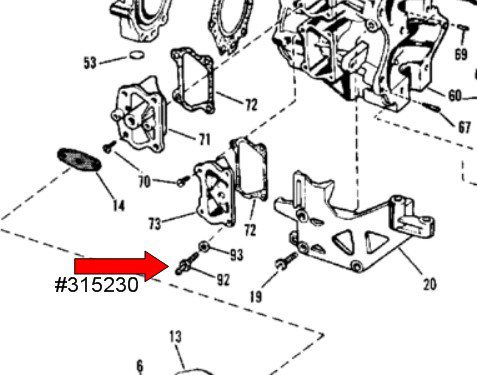

Starting 1968 part of the drainage system was eliminated, and what was left was routed through a hose to a fitting in lower bypass cover….actually one of the bypass cover bolts which was a combo bolt and fitting (part number 315230).

From there it went through the casting and into the exhaust area, where the heat was supposed to evaporate and “smoke off” some of the fuel & oil. The rest still went out the exhaust into the lake.

According to MarineEngine part diagrams this was done from 1968-1970 on 18, 20, 25 HP.

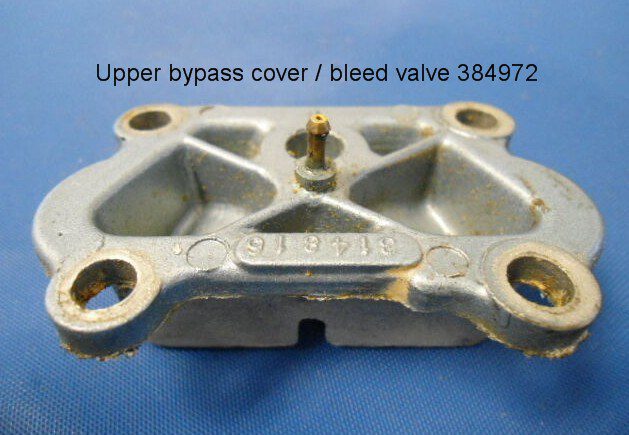

Starting in ’71 they re-routed the hose into a fitting in the upper bypass cover/bleed valve (part number 384972) so it would be drawn into the cylinder and burned. That caused mostly rich running in that cylinder and idling problems.

So yours is a little better system being a ’68-’70.

December 30, 2021 at 10:57 am #251959Yes, see if that combo bolt is in the lower bypass cover for sure. That dark green color was only used for a few years, so most likely a Johnson 20/25hp from 69-70. I would not split the block apart just to look at the recirculation system, unless the powerhead is damaged and needs rebuilding.

I don’t think it is a 71 model (a good thing), because your powerhead doesn’t have the nipple in the upper bypass cover. 68 models seem to show the fuel pump on the top bypass cover (might just be a mistake in the picture though). 71 brought the completely drainless recirc system which resulted in degraded idle quality, and some plug fouling issues.

Now to determine whether it is a 20 or 25hp model…. There were many subtle differences in these two models, it will take some more in depth investigation to make this determination.-

This reply was modified 3 years, 6 months ago by

fleetwin.

December 30, 2021 at 9:05 pm #252006I pulled the transfer covers off this afternoon. I found a stuck ring on one of the two ring pistons, and a score on the intake side of that piston. After a little carbon scratch’en I found where the gas/oil mix goes from the carburetor, right into the exhaust. Why did those engineers do that? Makes no sense to me. I think I am gonna block that port off completely.

thanks guys n Happy New Year!

December 31, 2021 at 9:08 am #252013See post by Steve D above. It is a 1968-70 22 cubic inch powerhead. That is the crankcase drainage hose, which dumps the drainage into the exhaust for evaporation/burning (or shall we say hiding?). 18/20/25hp have look-alike internal differences which are hard to distinguish without comparison with known parts, as said.

January 1, 2022 at 8:56 am #252085I pulled the transfer covers off this afternoon. I found a stuck ring on one of the two ring pistons, and a score on the intake side of that piston. After a little carbon scratch’en I found where the gas/oil mix goes from the carburetor, right into the exhaust. Why did those engineers do that? Makes no sense to me. I think I am gonna block that port off completely.

thanks guys n Happy New Year!

Not sure what you are questioning here. Are you saying that this recirc/dump system caused the stuck ring and scoring? I’m not that familiar with this initial step toward an overboard drainless system. I guess the engineers were hoping that dumping the excess puddling fuel/oil mix into the hot exhaust housing/chamber would ignite that mix and burn it off. I really don’t see much difference in this initial step and the drain system used before. Prior years dumped excess puddling fuel/oil into the exhaust housing through internal passages in the crankcase. This system seems to do the same thing, it is just more obvious. Perhaps this system was a “cost savings” over prior systems with the internal machined passages…. Who knows, just guessing.

But, I do know that if you block the exit passage for the puddling fuel/oil to escape, the engine will surely “load up” at idle and probably foul plugs. I really don’t think this system had anything to do with the stuck ring/scoring. I suppose you could install one of those nipples into the upper bypass cover and reroute the drain to there, I don’t recommend it though. These were the last 22CI engines that idled nicely. The 1971 drainless system brought degraded idle quality and plug fouling issues. -

This reply was modified 3 years, 6 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.