Home › Forum › Ask A Member › Pressure Tank Repair Kit

- This topic has 4 replies, 5 voices, and was last updated 8 months, 2 weeks ago by

Steve D.

Steve D.

-

AuthorPosts

-

October 31, 2024 at 10:20 am #291846

Greetings! I am helping a young man with his first vintage motor (1958 Johnson 7.5) and his pressure tank is leaking at the plunger. It has been quite some time since I worked on a tank but I seem to remember there being 2 kits available, one for the metal plunger and another for the plastic button. This tank has the metal plunger and its leaking and sucking air around it. I am trying to find the correct kit part number so I don’t advise him to get the wrong one. Can you guys help me with that and maybe point me to a supplier of original parts for it. I see lots of kits on Ebay but they are not original manufacturer and I don’t see a part number. So, I am a little unsure as to ordering one. Thanks!

October 31, 2024 at 10:58 am #291852I would suggest that you contact member Ed Elliot. He’s in the Direstory.

He will sell you the correct parts based on the tank you have. The kits that are available are (I think) built by individual sellers. I don’t think that OMC themselves offer a “kit” Just individual parts.

I have been hearing lately that; sure enough….there are Chinese variants of the gaskets and maybe some of the other components. From what I hear….stay away from those and stick to OMC or an other alternative sold by a reputable seller. Like Ed.

October 31, 2024 at 1:19 pm #291856vintageoutboard.com has kits

October 31, 2024 at 5:32 pm #291864Have you considered going pump ?

HOW TO CONVERT 50s motors from two line tanks

Joining AOMCI has priviledges 🙂

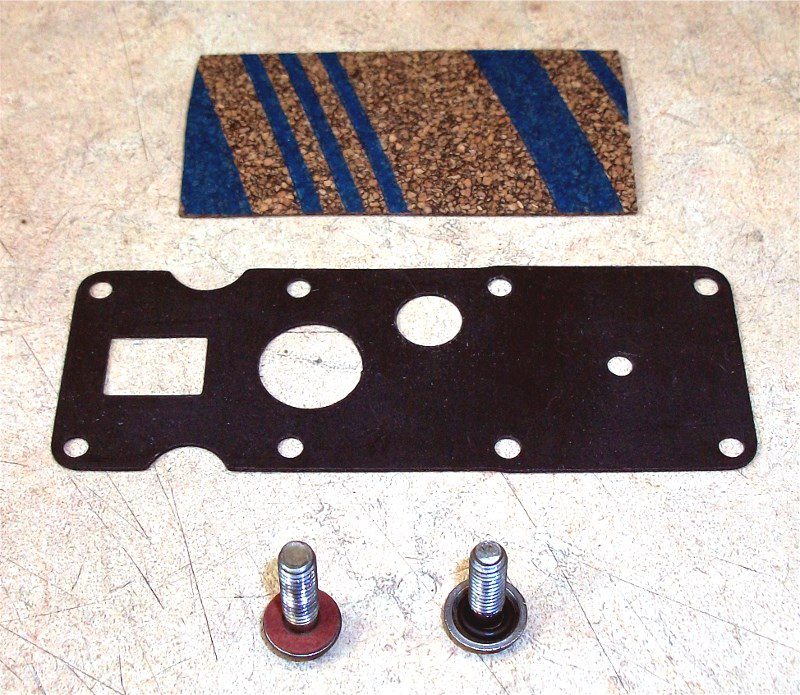

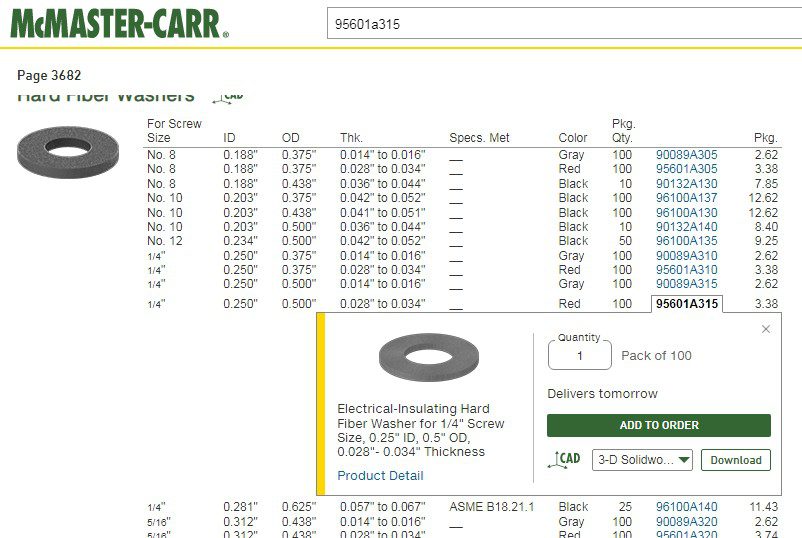

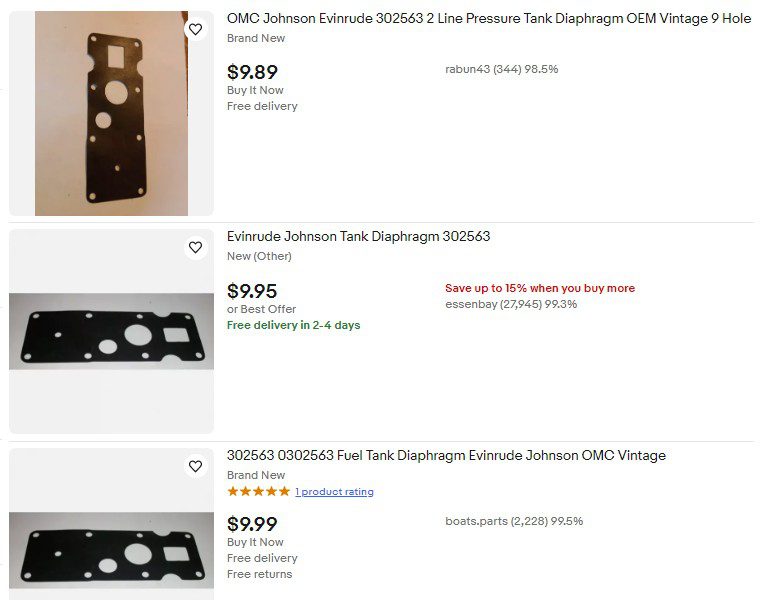

October 31, 2024 at 6:56 pm #291865You need the 302563 diaphragm for that tank (3 on ebay for $10 including shipping), I’ve used Fel-pro 3018 Cork Rubber Gasket Material for the tank gasket, and these hard fiber washers for the screws from McMaster Carr (if they’re the screws that use washers and not o-rings).

Also if you go this route here are a few words quoting Frank R. from a post a few years back:

“I use sealant (OMC Gasket Sealant) on both sides of the cork [tank gasket]. Screws, depends on which type it has. O-ring type, replace the o-rings, otherwise the washers type don’t really need anything but use sealant if they are in poor shape-or replace.

Diaphragm-no sealant needed. BUT if it is the metal push button type, the support discs have to be in good shape. Straighten them if bent in the center. I even go beyond flat a bit (the opposite of what tightening the nut does to them). If rusted around the center hole, either replace, or put the rusted one on the bottom if the other one is good (on top). Now for the push rod: The end right above the threads has to be in good shape and flat. If it is corroded/not flat, it will leak. Replace it. The knob: It is supposed to spin freely on the push rod. That is because if it won’t turn, when you push the button you have a tendency to rotate it, which unscrews the nut off the bottom-and it will leak. Finally, yes a drop of sealant (847 or Permatex aviation) on the threaded end and lockwasher, and flat end previously mentioned to keep fuel from going up through the hole.”

-

AuthorPosts

- You must be logged in to reply to this topic.