Home › Forum › Ask A Member › QD-20 compression.

- This topic has 19 replies, 7 voices, and was last updated 3 years, 2 months ago by

Mumbles.

Mumbles.

-

AuthorPosts

-

October 14, 2022 at 4:34 pm #267625

-

This reply was modified 3 years, 3 months ago by

Mumbles.

Mumbles.

October 14, 2022 at 6:48 pm #267640That might be a 1959 QD-20 but that’s a 1960 QD-21 cowl on it.

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1955 Johnson QD-16

1957 Evinrude Fastwin 18

1957 Evinrude 3022

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."October 14, 2022 at 8:08 pm #267653Hey! for $2.00 not bad.

October 14, 2022 at 8:38 pm #26765659 has pressure tank 60 + … fuel pump + one hose tank

Joining AOMCI has priviledges 🙂

October 15, 2022 at 7:13 am #267663This one has fuel pump. Only had spark on one cylinder. Cleaned points,shot pre-mix in carb and it turned over.Newer components under flywheel also.

-

This reply was modified 3 years, 2 months ago by

elgin2.

October 15, 2022 at 8:19 am #267666Well, the updated pistons/rods/wrist pins and bearings were introduced as a running change in 1960. So, if yours is actually a 1959, it has the older plain bushing set up, although it was a little more “beefy” in 1959 than previous years.

Your compression readings don’t seem that far off, perhaps try a different gage after running the engine some more. You definitely want to check for sloppy wrist pins though, very easy to check out.

October 15, 2022 at 9:40 am #267669he has a fuel pump introduced in 1960 …. unless it is a converted 59 ….

the tag should say what it is !

Joining AOMCI has priviledges 🙂

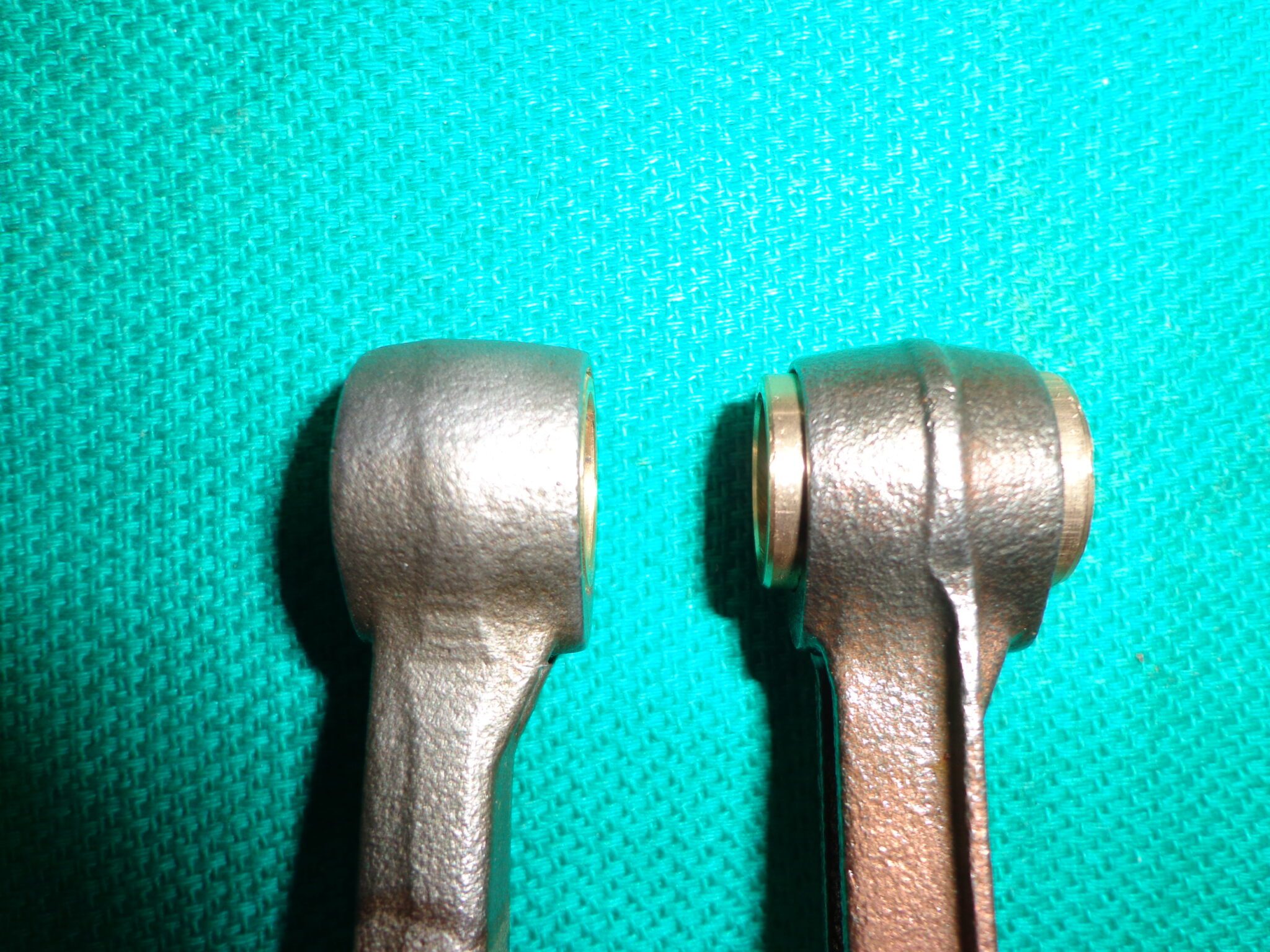

October 15, 2022 at 12:08 pm #267679QD and Sportwin motors are famous for excessive wrist pin bushing wear so starting in ’59 the small end bushing was made a bit wider than the earlier models. The real fix was on the 61-63 motors which used rods and pistons which accepted a larger diameter wrist pin with needle bearings instead of bushings. If you are going to rebuild one of these motors, it’s a good idea to replace the rods and pistons with ones from a ’61-’63 donor motor to avoid any wrist pin wear. The crankshafts are the same thru the years.

’57 rod on the left with the standard bushing, ’59 rod in the middle with the wider bushing, ’61 and later rod on the right with the improved wrist pin design.

October 16, 2022 at 3:39 pm #267739I have yet to get accurate pressure readings with a standard harbor freight compression gauge. The hoses are too long. I checked my 59 lark 35 hp yesterday and 60 on each cylinder, although I’m satisfied it’s much higher. 60 seems to be the largest number I’ve ever achieved on any engine and a bunch of em have been good runners. I need to take the time to build a simple short compression guage, as that’s where the trouble is with the small two stroke motors and testing

It's a jungle out there.

October 16, 2022 at 5:08 pm #267746 -

This reply was modified 3 years, 3 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.