Home › Forum › Ask A Member › Row boat motor ID

- This topic has 32 replies, 9 voices, and was last updated 7 months, 3 weeks ago by

Waunnaboat.

-

AuthorPosts

-

April 28, 2025 at 2:34 pm #295920

Another question for you wise ones, the arms on the transom bracket are broken off they may not have been original but I can’t seem to find an image of one to copy so if any of you have a RBM could you share a photo and give me the length of the arms. Cheers

April 28, 2025 at 11:37 pm #295940April 29, 2025 at 2:20 am #295944Thanks Tubs I can work off them, looks like I can make it out of one piece of flat steel and when in the down position it will extend about an inch past the exhaust can, might have to make a jig to get the bend 🤔 Thanks again I’ll plod along with it. The coil is shot so I will build a buzz box instead of trying to fix it.

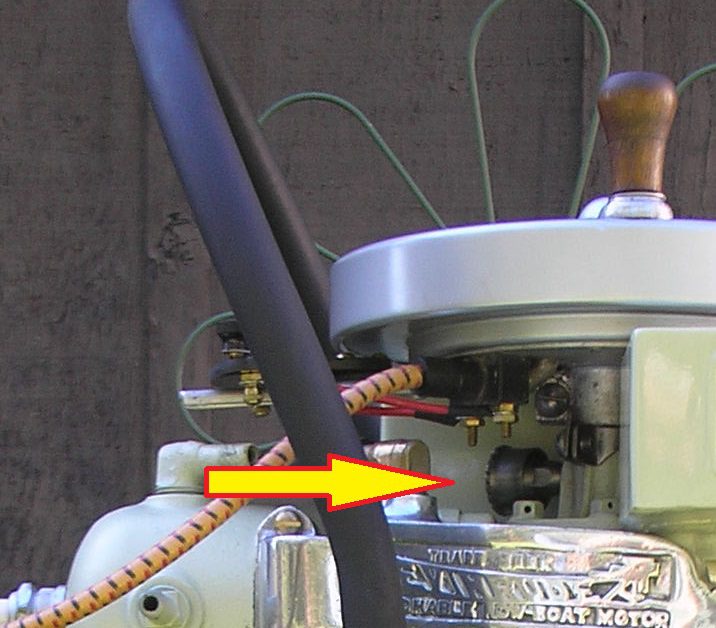

April 29, 2025 at 5:26 pm #295961Another question 🙂 this was in the box of bits it was full of grease, it looks to have been repaired at some stage and has a lot of brazing done on top with a square hole would there have been a grease nippel here 🤔 sorry for all the question this is my first time seeing one of these motor’s.

April 29, 2025 at 10:38 pm #295966

We are here for people to ask questions. That is the top main bearing lubricator. You fill it with grease and give it a twist every once in a while. I don’t have this motor anymore. This is the best picture I have.

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

1 user thanked author for this post.

April 30, 2025 at 4:54 pm #295992Do you know if there is ment to be a grease nippel on it or do you just pack it up by hand, Thanks again. Getting there with the bracket it’s not as strong but will not get much use.

April 30, 2025 at 5:30 pm #296000You would pack it full after removing the cap, then when you screw the cap down it forces a bit of grease out the end. A half turn or so every now and then.

David Bartlett

Pine Tree Boating Club Chapter"I don't fully understand everything I know!"

1 user thanked author for this post.

May 4, 2025 at 1:48 pm #296143Another question for you wise ones, on the little cam for the water pump there are holes that line up but the inner shaft is partly blocked and the outer one there is only a hole on one side, should there be some sort of pin or ball-bearing, cheers

May 4, 2025 at 10:43 pm #296186

Another question for you wise ones, on the little cam for the water pump there are holes that line up but the inner shaft is partly blocked and the outer one there is only a hole on one side, should there be some sort of pin or ball-bearing, cheers

No pin or ball. I believe the holes are there to let water pass through as it goes up and down moving the piston in the pump .

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

1 user thanked author for this post.

May 5, 2025 at 3:10 pm #296212Thanks again Tubs, I have another holey question, in the outer tube there’s a hole that lines up with a hole on the main shaft that appears to be treated should there be something in it 🤔 I hate fixing things that someone else took apart. Also if anyone could point me towards a good restoration link or video showing all the parts or a parts list and drawing that might help stop me asking all these questions 🙂

-

AuthorPosts

- You must be logged in to reply to this topic.