Home › Forum › Ask A Member › Shaking at High RPM Running 1955 Evinrude Fleetwin Aquasonic 7.5HP

- This topic has 50 replies, 10 voices, and was last updated 3 years, 8 months ago by

fleetwin.

-

AuthorPosts

-

August 15, 2020 at 9:05 am #211683

I pulled everything apart and back together again many times.The water tube appears to be aligned. I have not done a compression test on this power head. I first started experiencing problems with the water pump when i had to take out the bottom drive shaft. I used permatex water pump and thermostat housing gasket maker to seal the pump and gasket afterwards. The motor seems to only want to pump water when its submerged 2 or 3″ below exhaust port.When i hit the throttle and the motor comes out of the water and you can see the beveled edge of the skeg it stops pumping. Even though the holes for water intake are still submerged.At this point im thinking of installing a new water impeller.

August 15, 2020 at 9:06 am #211684One more thought….Did you use the correct base gasket when you replaced the powerhead? There are a couple of different base gaskets used depending on the year, the wrong gasket could create a leak or restrict water flow…

Sure hope I am wrong about this thought….What year powerhead did you use? Just like the gaskets, the powerhead castings are different between the 55 and earlier vs 56 and later models also…Unfortunately, the hole patterns are the same, so the wrong gaskets/powerheads will bolt is place just fine….August 15, 2020 at 9:10 am #21168554 powerhead I still have all the parts to the motor minus the shaft.

August 15, 2020 at 1:54 pm #211708One more thought….Did you use the correct base gasket when you replaced the powerhead? There are a couple of different base gaskets used depending on the year, the wrong gasket could create a leak or restrict water flow…

Sure hope I am wrong about this thought….What year powerhead did you use? Just like the gaskets, the powerhead castings are different between the 55 and earlier vs 56 and later models also…Unfortunately, the hole patterns are the same, so the wrong gaskets/powerheads will bolt is place just fine….Good thought!! I’d heard about the possible gasket mismatch in a MaxW article, and asked about it (on the blue board before the blueboard before this one):

http://www.omc-boats.org/phil/5.5+7.5-gaskets/

Here is the notes file from that folder:

https://www.aomci.org/cgi-bin/yabb2/YaBB.pl?num=1367261609

Me:

I’ve heard the OMC 5.5 hp and 7.5 hp exhaust gaskets can be mistakenly used (with bad or no cooling resulting). Can anyone post pictures of both and point out the difference?FR:

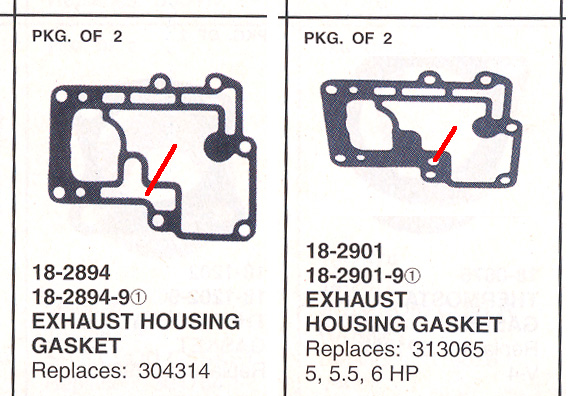

There are three kinds, The main determining factor is the motor’s mounting systems. Spring mounted motors use one kind and rubber mounted use another. You can tell the difference by seeing if they fit all the passages.303467 fits 5.5 & 7.5 with spring mounts

304314 fits 5.5 & 7.5 with rubber mounts

313065 fits 5.5 & 6 with rubber mounts and thermostat.You can use a 313065 for a 304314 by enlarging the water inlet hole. 303467 is too much different to substitute.

FR:

Sierra still makes both 304314 and 313065. As you can see, the difference is the hole (arrow). I agree with BRP if they don’t use the 1/4″ hole in the 313065 any more. I never could see any sense to it.

Mumbles:

Here’s something funny. The last time I picked up the 304314 and 313065 gaskets at the dealer, they were priced slightly different even though they are identical.

================================================================

https://www.aomci.org/cgi-bin/yabb2/YaBB.pl?num=1385399477/1#1Don:

OK, so the gasket that is completely cut out if for the 56-58 models. The gasket with the little hole is for the 54-55 spring mount models. The little extra flap on the gasket with the little hole isn’t really used…I guess this way they can simplify the manufacture of the two style gaskets.

OK, this was very helpful, thanks!!Don:

The gasket with the restrictor hole is for the thermostat models, the gasket that is cut out is for the non thermostat rubber mount models…

I would think that the non thermostat gasket would work fine on the thermostat models, because the thermostat is the “restrictor”…

BUT, the best way to figure it out is to pull a thermostat powerhead off, which I will be doing soon…

I’m thinking that Bill used the thermostat gasket, the one with the restrictor hole (313065), and just cut the tab off…Of course, the little hole in the gasket must line up with the hole in the exhaust hsg/powerhead. I guess the engine would have overheated instantly if the holes didn’t line up..To me, that would work fine on the 54-55 spring mount models….But, like Mumbles says, if you used the non thermostatl rubber mount gasket (with the cut out) on the spring mount engines, there would be a leak…OK, I’m even confusing myself now….

Thanks for the help, alot learned….http://www.omc-boats.org

http://www.aerocraft-boats.orgAugust 15, 2020 at 1:57 pm #211709And the BRP.jpg file from the above:

http://www.omc-boats.org

http://www.aerocraft-boats.orgAugust 15, 2020 at 2:12 pm #211710sierra file from above:

http://www.omc-boats.org

http://www.aerocraft-boats.orgAugust 15, 2020 at 2:57 pm #211718Phil

Not really understanding what you are referring to with the gaskets… I don’t really understand why they need the two different gaskets for the (1956 and newer) non thermostat vs thermostat models. It sure looks like the 313065 in your first picture was packaged incorrectly….LIke you said, the 313065/thermostat models gasket usually has the small hole in it, the one in your picture seems identical to the 304314 gasket in your picture. All I know is that substituting the 56-58 and thermostat gaskets for the 303467 gasket and vice versa will result in a cooling leak under the powerhead….GF Your description confuses me also. First off, please know that the engine must be buried deep in the water when running in a test tank, the water level needs to be up and over the gearcase to exhaust housing joint (where the four bolts are). Trying to run the engine at high speeds in a test tank can cause cooling issues because of the turbulent water/air swirling around….But, seems like you report the engine only pumps when the throttle is up high. Did the water pump work correctly with the original powerhead?? If so, I am still worried that you may have a mismatched powerhead/gasket situation…Your engine uses powerhead gasket: 303467, the gasket on the right…Using either of the other gaskets will result in a cooling leak under the powerhead. Are you sure your replacement powerhead is from a 1955 or earlier model? Perhaps the ID plug is still on the powerhead, post the model number here if it is there. The ID core plug is on the right side of the powerhead down next to the base gasket.

OK, so you have not replaced the impeller. Please know that no sealer is used between the aluminum impeller housing and the SS impeller plate…Using sealer here will result in the sealer ooozing out into the impeller cavity diminishing impeller performance. Yes, this surface needs to seal properly, but cleaning the smooth SS plate and the impeller housing mating surface should offer good sealing on its own…Needless to say, if these mating surfaces are damaged/gouged/corroded, sealing will be affected, and the offending part(s) should be replaced. The SS impeller plate should not be grooved excessively where the impeller spins, same goes for inside the aluminum impeller housing. Replace these parts if they are worn excessively…

All that being said, the surface between the aluminum upper gearcase bushing/seal housing and the bottom of the SS impeller plate should be sealed…The OMC type M/ 847 sealer should be used here, or something similar. Needless to say, if the mating surfaces are damaged/gouged/corroded, the water pump will suck air instead of water, the damaged pieces should be replaced.

I would definitely pull the powerhead again, check to make sure you have the right powerhead and gasket. Once the powerhead is off, I would removed the gearcase and inspect the impeller housing and SS plate…Replace the impeller using an OEM piece, I have heard some negative feedback about the aftermarket stuff…

Once everything is apart again, feel free to post pictures if you have any questions, do so before reassembly. Don’t feel bad, I’m having a fight with a 6hp now, this will be the third time I have had to remove the powerhead and gearcase…This bugger is a fighter for sure!August 16, 2020 at 6:58 am #211767If the powerhead is a 1954, then it likely has been cast to receive an identifying welch plug, but will not have a plug. At least that’s been my experience. If you try to put a 1956 or later powerhead on the 1954 or 1955 motor, then the starter mounting bosses will not fit to your 1954/1955 starter housing. The 1956 and later have a totally different starter and flywheel. Different base gaskets also pose a problem as fleetwin mentioned.

Regarding the cooling issue, if all of the passages are clear, grommet is in good condition and not partially folded over, pump, key, housing, and plate are in good condition, then the problem could be sealant partially blocking off the water passage, again as fleetwin mentioned.

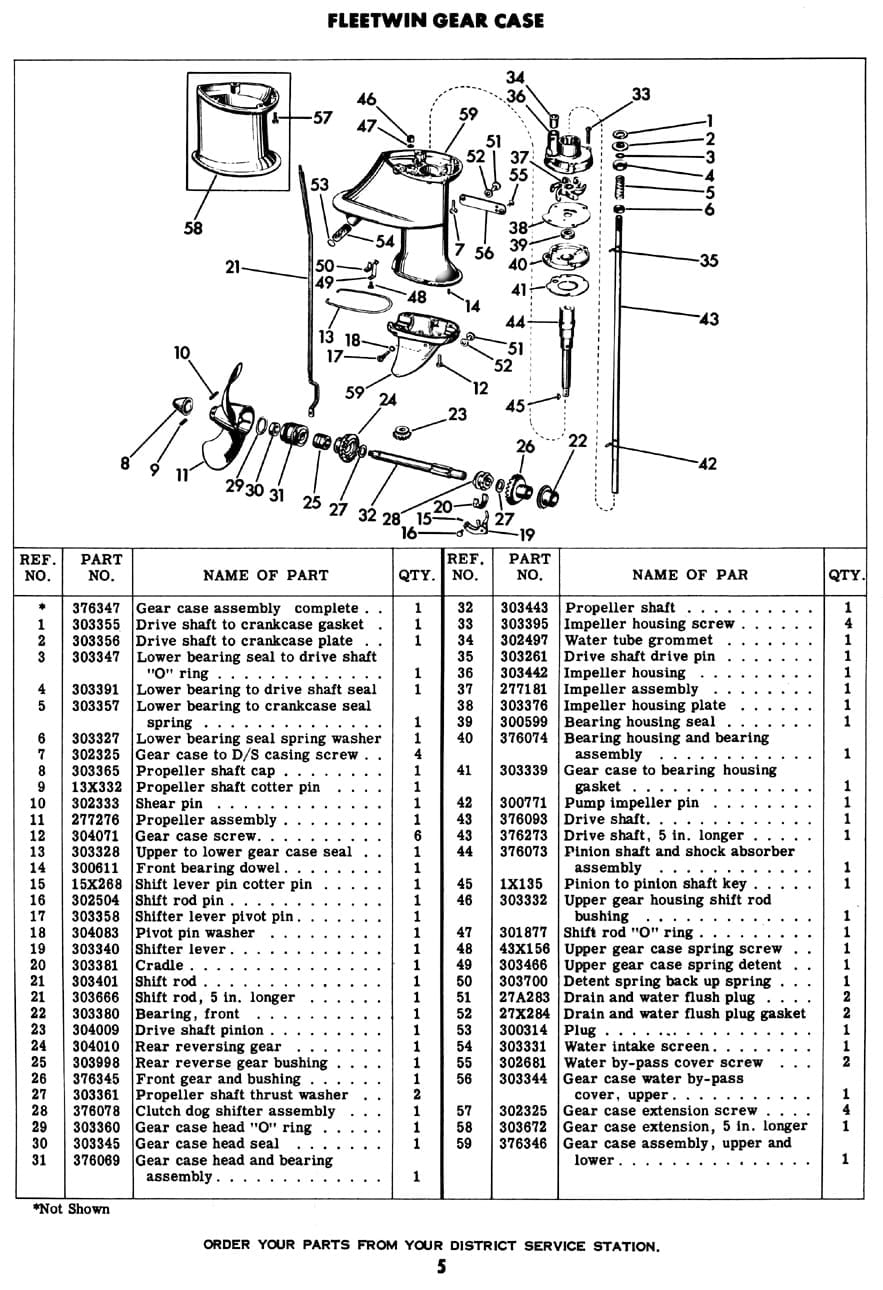

There is one other thing that can go wrong during assembly, and it happened to me. Part 41, 30339 Gearcase to Bearing Housing Gasket was installed with a light coating of gasket sealer, on a 1954 Johnson 5.5. When installing the water pump assembly and housing, the gasket rotated slightly thereby partially blocking off the cooling port opening in the gasket. I didn’t even notice that the waterpump housing screws were misaligned to the gasket, and they were easily forced through the gasket, and made there own holes. This was a valuable lesson, and ever since, I always use alignment pins when installing the assembly and housing.

August 16, 2020 at 9:49 am #211778Aqua raises a good point, one that has always confused me….What the heck was that gasket designed that way….Why didn’t they design the outer diameter of the gasket a little larger so it conformed better to the gear housing and upper bushing/brg assy. Those little cut outs for the water pump screws are ridiculous…And, the gasket would seal much better if its outer diameter was bigger and conformed properly to the bushing and housing…

I forgot about the different recoil mount positions of the two versions of powerheads….So, it seems very unlikely that the powerhead is a mismatch…The base gasket is still suspect though…August 16, 2020 at 11:57 am #211796 -

AuthorPosts

- You must be logged in to reply to this topic.