Home › Forum › Ask A Member › Stubborn Flywheel, Gale 40 hp

- This topic has 50 replies, 14 voices, and was last updated 4 years, 7 months ago by

phil.

phil.

-

AuthorPosts

-

July 21, 2019 at 5:43 pm #179271

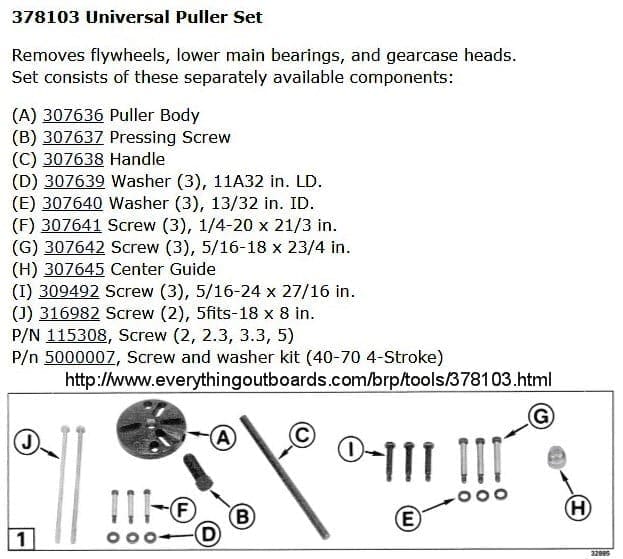

Buc, If all you want are the bolts for now, it looks like any of the ones that come with the OMC puller you can get at Crowley Marine for a decent price. I bought the puller 3 years ago and glad I did. Also the price went up $15 since then.

https://www.crowleymarine.com/parts/38822.cfm?q=0307641July 21, 2019 at 6:04 pm #179279Thanks for the link Steve. Did OMC make one heavy dutier?

With those big slots in the puller plate, and thinking about

all the force I had on my puller, you’d think that hub would

bust out around slots???

Crowley’s puller seems to be the same puller as this on on EBay,

but the prior is much cheaper.

https://www.ebay.com/itm/Universal-Puller-Flywheel-Johnson-Evinrude-378103-0378103-OMC-766525/173151348193?epid=1549785065&hash=item28509fe5e1:g:KAoAAOSwjXNafgH4Prepare to be boarded!

July 21, 2019 at 6:32 pm #179281I got mine at Crowley’s. It cost less than what Ebay had at the time, same thing now. It has the correct # stamped into the puller body (for what that’s worth) and brevard has 100% feedback and I’ve got stuff there before. But saved money at Crowley, and they’re good too. I don’t know if OMC made a heavier one…one of the long-timers would know.

July 26, 2019 at 7:44 pm #180327Hi; I don’t know what I’m talking about, so listen to me at your own risk. But, I’ve found that using a bit of wheel bearing grease on the threads of the center bolt of the puller has been helpful on several occasions. As tight as it all is, the friction on the threads uses up some of the force applied. And, for what it’s worth, I had good luck sort of sneaking up on it with the air impact. After lubing, hand tighten the center bolt most, (but not all) of the way. Then tighten it all the way with the impact. After making utterly sure the puller is pulling straight up, of course.

I hope someone will issue correction if this is a bad idea.

Very best of luck!

Happy motoring to all.

Alan-

This reply was modified 4 years, 9 months ago by

Alan.

July 26, 2019 at 7:58 pm #180329Hi; I don’t know what I’m talking about, so listen to me at your own risk. But, I’ve found that using a bit of wheel bearing grease on the threads of the center bolt of the puller has been helpful on several occasions. As tight as it all is, the friction on the threads uses up some of the force applied. And, for what it’s worth, I had good luck sort of sneaking up on it with the air impact. After lubing, hand tighten the center bolt most, (but not all) of the way. Then tighten it all the way with the impact. After making utterly sure the puller is pulling straight up, of course.

I hope someone will issue correction if this is a bad idea.

Very best of luck!

Happy motoring to all.

Alan

Sounds like great advice to me….And yes, the 1/2″ impact is a great helper also…

July 26, 2019 at 8:35 pm #180335My OMC puller is suppose to arrive tomorrow (from Crowley).

I did tighten my other puller for all she’s worth with my 1/2″ impact

and then an 18″ pipe wrench with a cheater pipe on that…. to

no avail. I put some never seize on the threads of the other puller,

but it was a course thread center bolt. My only hope is that the

OMC puller with the fine thread center bolt torques down tighter

and results in a thunderous “POP” !!

Going to a flea market in the morning to scrounge for outboards,

but hope to try the puller out in the afternoon.Prepare to be boarded!

July 26, 2019 at 8:44 pm #180336If your using heat, sometimes melting wax in the stuck area will help. A sheared flywheel key will also add to the misery.

July 26, 2019 at 8:47 pm #180337If your using heat, sometimes melting wax in the stuck area will help. A sheared flywheel key will also add to the misery.

I’ll have to try the old “wax” trick some time. I did spray about a half can of PB Blaster around the flywheel nut though, lol.

Prepare to be boarded!

July 26, 2019 at 11:12 pm #180342make sure you leave the nut on a few threads so it does no fly off and hurt some one.

July 27, 2019 at 8:15 am #180346make sure you leave the nut on a few threads so it does no fly off and hurt some one.

That’s always good practice for the reason you quote Dave, and to help prevent

the threads getting buggered up.Prepare to be boarded!

-

This reply was modified 4 years, 9 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.