Home › Forum › Ask A Member › Transom wood

- This topic has 14 replies, 12 voices, and was last updated 5 years, 7 months ago by

fountain.

fountain.

-

AuthorPosts

-

September 21, 2018 at 4:22 am #83306

Gentlemen (and Ladies):

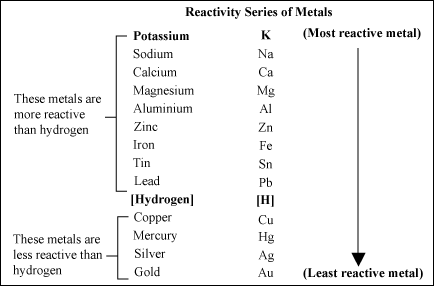

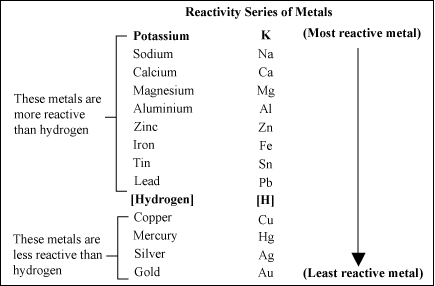

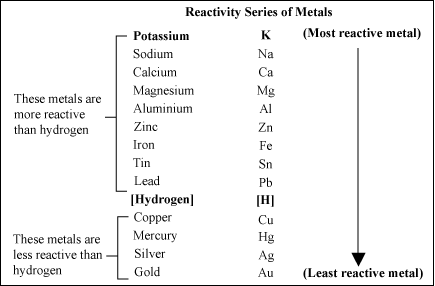

I am new to this forum, but I am not at all new to materials. I have followed discussions of transoms on this and tinboats, and I think that all of you might want to be reminded about what you learned in High School chemistry – the electromotive series of metals.

Yes, Pressure Treated (PT) plywood will cause accelerated corrosion of aluminum. PT pine plywood is infused with copper compounds; copper is anti-fungal, which is what you want in a 4X4 post in the ground. The most common pressure-treating in bygone years was CCA – Chromated Copper Arsenate. The copper compounds were to resist rot, the arsenic kept bugs from eating your fenceposts. It worked great. But the American Wood Protection Association (AWPA), in their wisdom, decided, with encouragement by the EPA, to eliminate the arsenic. Pressure-treating industry went to MCA, Micronized Copper Azole. But it still contains copper, lots of it; you have to use stainless or ceramic-coated fasteners with it, galvanized won’t survive.

If you want to read more about recent pressure treating, go here: https://en.wikipedia.org/wiki/Wood_pres … technology

Here is the Activity Series for common metals;

https://d2gne97vdumgn3.cloudfront.net/a … 29EBuActGX

To understand it, the metals lower on the series are more “noble” than those above it, meaning that when two are in contact with each other, they set up an electrochemical cell, and the lesser of the two is corroded. This is the reason for zinc-plating steel; the zinc becomes the sacrificial anode, and corrodes before the steel can. The Al-Can pipeline has plates of zinc attached to it to slow corrosion of the steel pipe. So when aluminum is in contact with copper (or any copper alloy, like brass or bronze), it is the aluminum that will corrode. The action is accelerated in the presence of water, even more so in salt water. See the hydrogen between copper and lead? Water is an electrolyte. Going from top to bottom, the metals lose electrons more readily to form positive ions – this is the way batteries work. Dissimilar metals in an electrolyte = electricity. The less noble metal is consumed to give up its electrons.

And George? The fault is not the pine in plywood. Because it is cross-laminated, plywood, any plywood is stronger, pound for pound, than almost any solid hardwood. (That doesn’t mean that it is harder – strength and hardness are two separate things) The problem is that pine, Baltic birch, any plywood you can name, will not resist rot unless it is pressure-treated.

I am always amazed that people on forums don’t really know anything about the chemistry of the materials they are thinking of using on their boats, and thus cannot make informed judgement of the product to use. They go by anecdotal recommendation, maybe twice or thrice removed. And that goes for finishes, as well.

No, I am not a chemist; I just know something about the practical chemistry of objects.

September 21, 2018 at 5:29 am #83308Apologies for that triple-insertion of the reactivity series. Forums differ in how one may insert images. Next time, I’ll check Preview first.

September 21, 2018 at 9:12 pm #83329I’m glad someone brought this topic up because I was just about to buy some pressure treated wood to replace my transom! Where do you acquire the marine grade plywood?

September 22, 2018 at 4:03 am #83350You should not discount PT plywood for transoms; but understanding the copper’s effect on aluminum, one needs to take precautions. My son made a PT transom for his boat, but he bought a sheet of 1/16" polyethylene to put between the PT and the aluminum of the stern, effectively isolating the dissimilar metals. And do not forget to put a dab of silicone putty on each screw to keep the metal of the screws from connecting copper to aluminum where they pass through the stern.

By the way, marine plywood is not the Be-All and End-All for transoms. Yes, it is much higher quality than construction or cabinet-grade plywood, with no voids, with (sometimes) plies from naturally rot-resistant tropical woods, but it is not treated to resist rot. And it’s not possible to put enough varnish on wood to completely exclude moisture. Wood finishes don’t work that way.

Perhaps I should post a paper I wrote for tinboats.net, about wood for transoms. It’s too long for a single post; Moderator, how do I do a link to it?

This from Wiki about Marine plywood:

MARINE PLYWOOD

Marine plywood is manufactured from durable face and core veneers, with few defects so it performs longer in both humid and wet conditions and resists delaminating and fungal attack. Its construction is such that it can be used in environments where it is exposed to moisture for long periods. Each wood veneer will be from tropical hardwoods, have negligible core gap, limiting the chance of trapping water in the plywood and hence providing a solid and stable glue bond. It uses an exterior Water and Boil Proof (WBP) glue similar to most exterior plywoods.

Marine plywood can be graded as being compliant with BS 1088, which is a British Standard for marine plywood. There are few international standards for grading marine plywood and most of the standards are voluntary. Some marine plywood has a Lloyd’s of London stamp that certifies it to be BS 1088 compliant. Some plywood is also labeled based on the wood used to manufacture it. Examples of this are Okoumé or Meranti.

September 25, 2018 at 1:29 am #83492I wrote the attached paper after going with my son to a number of AOMCI meets, and hearing members puzzle about woods for transoms, hearing many repetitions of "common knowledge", most only partially correct. I have seen similar queries on tinboats.net; the question seems to keep coming up, regularly, and seems a source of constant confusion.

So I decided to explain what I know from experience with wood and finishes, and back it up with citations of studies.

If you really want to know about the properties of wood, check out Bruce Hoadley’s book, "Understanding Wood", Taunton Press, 1980 ISBN 0-918804-05-1. But it may contain more technical information than you want to read; check it out of your library before you buy a copy. And the Panshin & DeZeeuw text mentioned in the paper has a lot of interesting information, but it is mostly intended for wood technologists, for microscopic identification of wood at the cellular level.

Clint Fountain

Graduate, Smithsonian Furniture Conservation Program, Class of 1993.Oh – I know a number of AOMCI members are also subscribers to tinboats.net. Would one of you link this thread to them, please, save me from signing up with another forum? Thanks.

-

AuthorPosts

- You must be logged in to reply to this topic.