Home › Forum › Ask A Member › TUBE BENDING

- This topic has 28 replies, 17 voices, and was last updated 8 years, 1 month ago by

jeff-register.

-

AuthorPosts

-

November 4, 2017 at 1:25 am #66996

There is an alloy of 50% bismuth, 26.7% lead, 13.3% tin, and 10% cadmium by weight that was developed by Barnabas Wood in 1860. It has a melting point of 158 degrees Fahrenheit. Woods Metal has many uses. . . 🙄

November 4, 2017 at 2:20 am #66998

November 4, 2017 at 2:20 am #66998Try freezing the pipe. Check about 3 mins into this vid. Vid is pertinent to tbis thread in a couple ways!

November 4, 2017 at 3:24 am #67002That is a pretty tight radius for that size tube. I think you will have trouble with anything other than a proper tub bender. I don’t know what you are making but have you considered making it up out of fittings? You can get return bends (180 deg) from a refrigeration supply house.

December 26, 2017 at 4:12 pm #69012quote ratrodz:Anyone have good luck bending soft copper with spring benders? I have a 5/8 OD soft copper

tube that I want to bend 180 degrees to a 2" radius. Should I try a 5/8" spring, I heard they get stuck, or 3/4"?

Bob HuffA "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

December 26, 2017 at 5:24 pm #69015If anyone wants to pick up the spring set that Tubs recommends.

https://www.ebay.com/itm/Spring-Tube-Be … 0305!US!-1

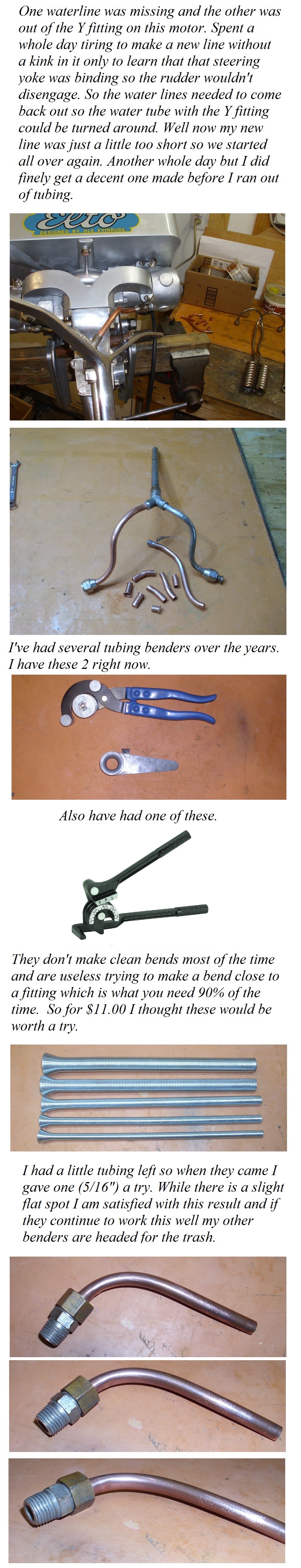

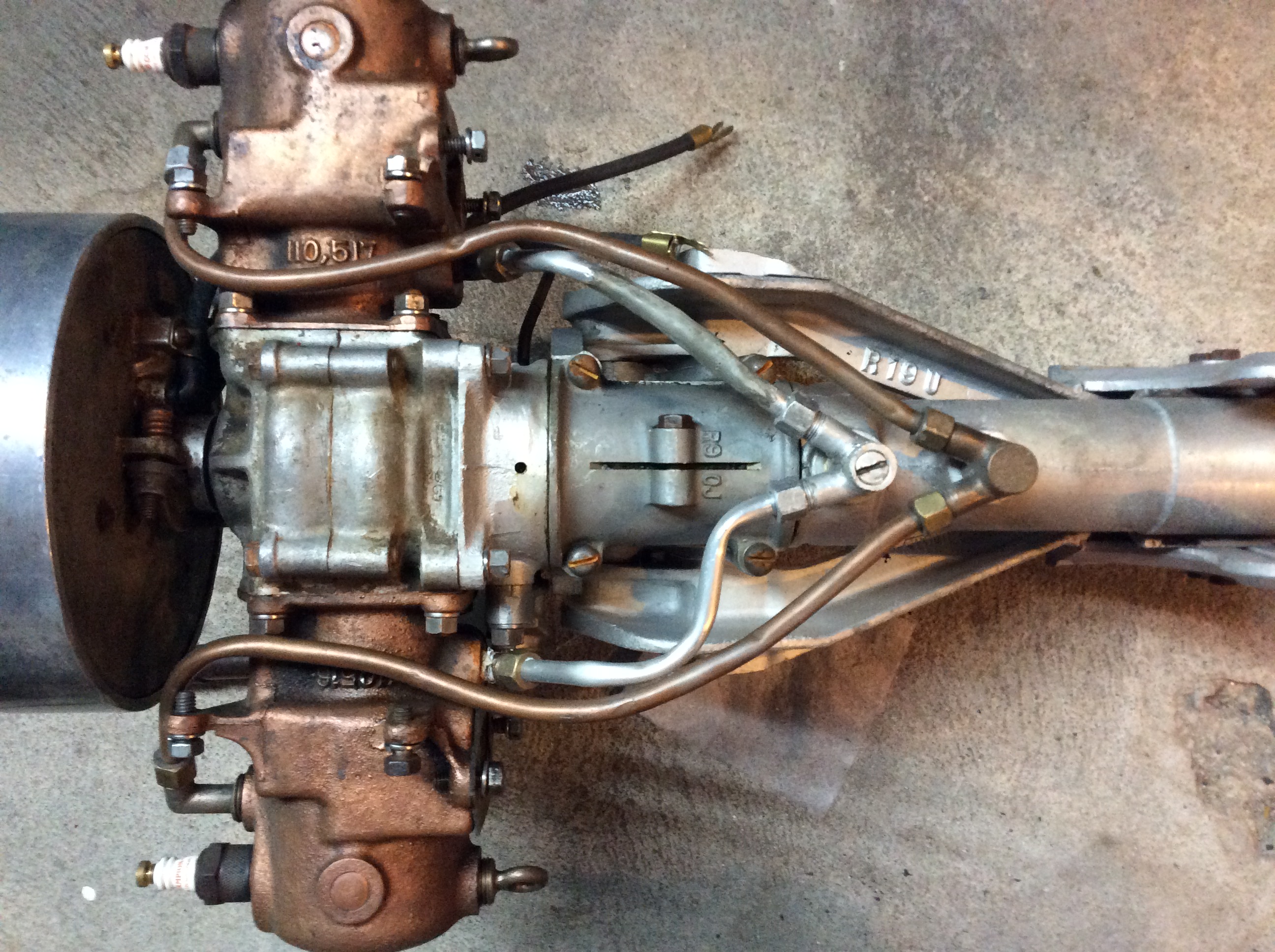

I’m going to get a set, as I have also tried all of the other methods without success. The aluminum water lines on a 1929 Evinrude Fastwin were a killer. After most of an afternoon they still had a load of kinks.

Bob DDecember 27, 2017 at 2:36 pm #69025Bob, What size is the tubing on your Fastwin

and what are you using for replacement tubing?A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

December 27, 2017 at 4:19 pm #69028Anyone know how the tubes were originally manufactured?

December 27, 2017 at 10:26 pm #69029Tubs, I used a 3/8” OD thin wall tubing I found on eBay. I looked for the link, but didn’t see that posting anymore. I could dig around through my receipts if you want to buy from the guy.

I’m almost embarrassed to post pictures of my tube bending expertise.

I even cracked the right one, and put some JB Weld on it…. geese what an armature I am.

Thought it would be ok with the low pressure application. Never got the motor to start, and put it on the back burner. Don’t even get me started on those bizarre end fittings that Evinrude used in the 20’s.

Bob DDecember 27, 2017 at 10:44 pm #69030Meant to say amature, but maybe I am an armature as well!

December 27, 2017 at 11:38 pm #69032Is the aluminum tubing pretty soft

and bend easily or is it hard to bend?A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

-

AuthorPosts

- You must be logged in to reply to this topic.