Home › Forum › Ask A Member › Backfire/misfire thru carb

- This topic has 105 replies, 9 voices, and was last updated 1 year, 10 months ago by

Beno.

Beno.

-

AuthorPosts

-

August 26, 2020 at 5:37 pm #212759

Well, all you can do is get this powerhead syncronized properly and try again. Pull the carbs apart and inspect the low speed jets if problems persist after proper syncronization. The pictures you posted look as though the butterflies are closed. But, don’t forget to disconnect the link between the two carbs and retest, just in case the linkage is preloaded open.

You still have the carbs from the damaged powerhead, perhaps you could try those as well. Keep in mind that the jet drive and conventional outboard are completely different animals, the original carbs are probably jetted much differently for this application. The one big difference between the carbs is that the old 140 uses a conventional choke, the newer jet drive uses the electric primer. So, you will have to transfer the primer valve and plumbing over also. The carb to intake gaskets are different also, the older gaskets don’t have a hole for the primer hose to spray…

You can’t tell much by revving the engine up in neutral, even though this jet drive doesn’t really have a neutral. And yes, the position of the throttle cam linkage will make a difference….

Good luck, sure hope I am wrong about that older powerhead. Don’t forget to do a compression test…August 26, 2020 at 7:31 pm #212764Ok. I went up and checked into it. The good news is i checked the compression. 128,128,123,122

I realized the trigger plate was siezed.. the connecting linkage came off as i investigated. I put some pliers on the exposed part and started working it. I must have moved it 2000-4000 times and hit it with pB blaster. Its not usable yet but its a lot better.. i advanced the plate just a bit and the idle cleaned right up. So thats the good news.

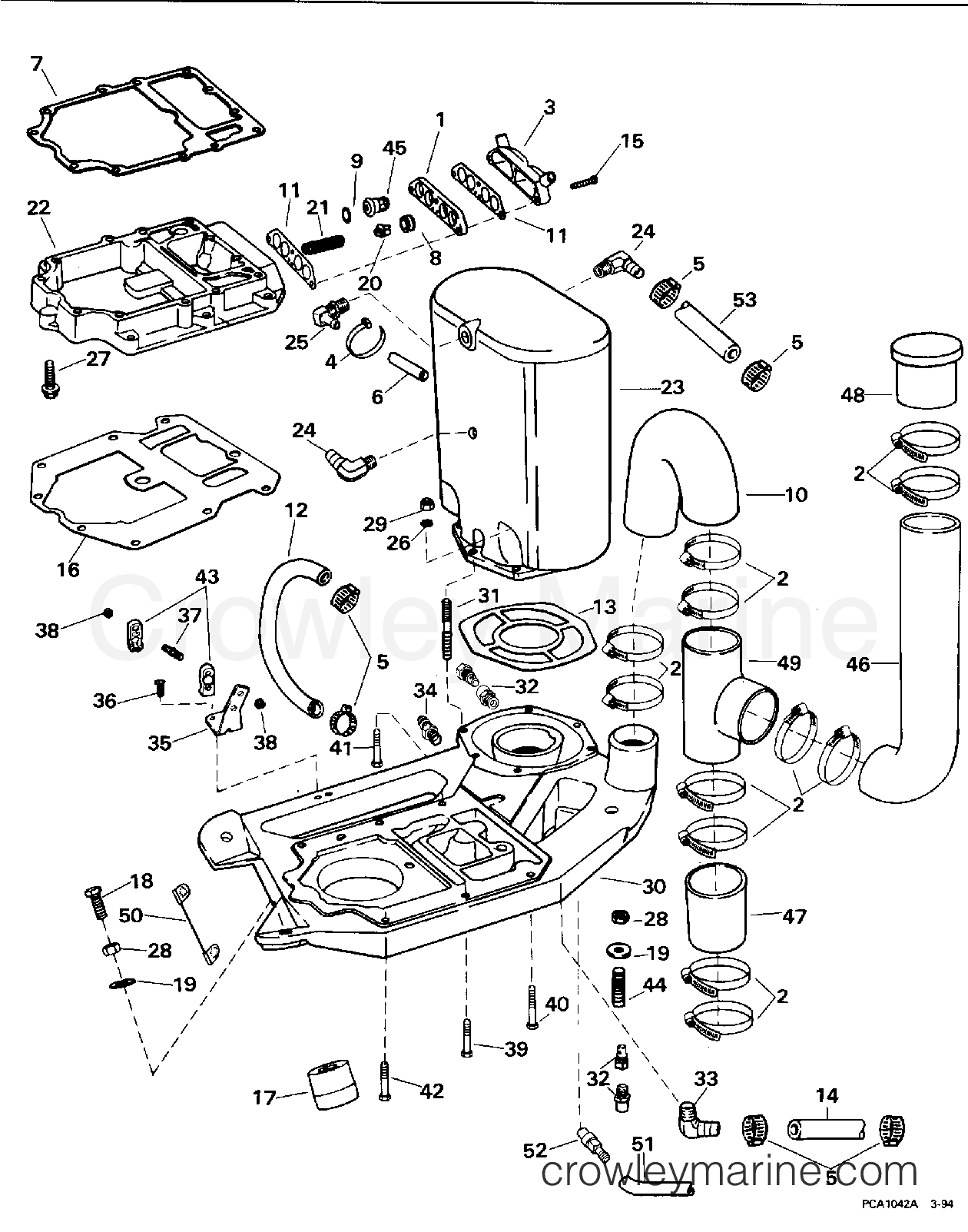

I pulled the cooling water supply hose ans poured some water down it and blew it to pressurize it a bit.. water started coming out under the engine. The exhaust adapter plate is likely frost damaged. Uggh. Ill have to pull the engine and inspect.

Water also came out under the bubbleback… not good.August 26, 2020 at 7:40 pm #212767August 26, 2020 at 7:42 pm #212768So at this point the questions are now.. how can I free up the Trigger/Ignition plate without removing the flywheel? Can I spray PB Blaster down the flywheel puller holes without damaging anything?

and If I have to pull the flywheel what is the correct re-torque ft lb number (and how on earth do you hold the flywheel while torquing?)

August 27, 2020 at 8:00 am #212802OK, well a jammed mag plate will certainly affect sync and running for sure. The sensor/trigger assembly has two different bushing surfaces. One is the pilot bushing on the inside diameter of the upper bearing assembly. I guess it would be possible to spray WD40/PB blaster through one of those puller holes, it will probably make its way down to the pilot bushing. The other surface is the plastic bushing that rides on the outer diameter of the assembly and sits down on top of the outside of the upper bearing assembly. You can see what appears to be a white plastic washer between the sensor assembly and upper bearing. You can try spraying the WD40 around where the plastic bushing is, it might work its way inside. It will be difficult to see this on your turbo jet.

To remove this flywheel, you will need the OMC puller assembly, don’t attempt it with a substitute puller. A big impact gun will remove the flywheel nut, and can be used on the big center puller screw for flywheel removal. Reinstallation will require a big torque wrench and a ring gear holder tool to secure the flywheel while using the torque wrench. Will get back to you with the torque spec.. Unfortunately, sounds like someone left water in this unit during the winter and popped the adapter open….What a mess.

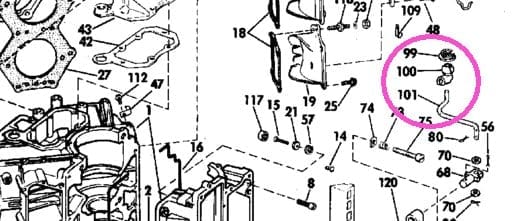

I should have asked how you were running the engine prior to now, seems like you were running it with no water…Won’t hurt anything on this unit, there is no rubber impeller. But, running the unit out of water reduces back pressure and could cause the unit to run lean/sneeze at idle. Maybe a good welder can patch up the cracks…Unfortunately, these turbo jet units were not OMC’s finest hour….August 27, 2020 at 9:07 am #212807Ok I will try the penetrating oil.. personally I’d rather work that trigger for hours than pull the flywheel, I’ve done it in the past and it creates such a issue. usually they just WILL NOT release. also the weird plastic thingie that hooks the linkage to the trigger plate (timing linkage?) is weirdly loose and doesn’t hold the linkage very well, any pressure and it falls down and out .. is that normal? circled:

otherwise I will pull the motor, I have one mystery water leak near this thermostat assembly under the motor shown in the attached picture of a similar motor.

my question is.. does the thermostat (when hot) allow water to “A” Drain down from the cylinder jackets, or to “B” travel up into the cylinder jackets… the only thing that makes sense to me is “A”.August 27, 2020 at 12:34 pm #212832August 27, 2020 at 12:34 pm #212833OK, well those white plastic connectors are fairly flimsy even when in good shape. But, this one has probably been worn out trying to move that jammed mag plate, I would definitely replace the ball/socket assembly.

The water flows out of the cylinders down through the hoses to the thermostats. So, is this the only leak you have?? If so, perhaps the big adapter is not freeze damaged. Perhaps one of the hoses is leaking, or one of the thermostat cover gaskets is NG. This set up is a pain in the butt at best, but near impossible to service with the bubble back exhaust. I have spent many hours trying to wrestle the little springs/seals back together while the powerhead was in place. In the end, it probably would have been easier and taken less time to just pull the powerhead. But, I would try to pinpoint the actual leak prior to pulling the powerhead so you can be sure it is actually fixed after reassembly. The last thing you want is to complete the job only to have the leak persist. I’m not sure if there is some way to run water through the system without running the engine, which might make it less difficult (and safer) to find the actual leak.

Good luck…August 27, 2020 at 3:40 pm #212858No Two leaks, the major one is below/under and the smaller one below the thermostat plate.

But You know whats interesting.. is looking at the design of the plates. I should have noticed a crack of this magnitude, That is a huge miss.

I’ll put the Video scope on it and get you all some pics of the damage thru the scope if I can.

-

This reply was modified 4 years, 10 months ago by

Beno.

Beno.

August 27, 2020 at 5:29 pm #212864I haven’t had much experience with these things, but it seems like the powerhead and adapter are going to have to come out of there in order to have the cracks repaired… I don’t think you could have seen a crack underneath that exhaust/adapter housing very easily. And, it sounds like the powerhead was shot, so you couldn’t run the unit to check for water leaks. Just hoping you didn’t pay much for this rig….

-

This reply was modified 4 years, 10 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.