Home › Forum › Ask A Member › Backfire/misfire thru carb

- This topic has 105 replies, 9 voices, and was last updated 1 year, 10 months ago by

Beno.

Beno.

-

AuthorPosts

-

August 27, 2020 at 10:25 pm #212885

I stopped by the boat in Amsterdam for a second, i hit the 3 puller holes full with PB Blaster and walked away..

a minute later I looked and there the PB was.. topped off and sitting in the holes.. They don’t see to go all the way thru the flywheel!!! augh! so i worked the ignition plate some more.. it gets a tiny little bit better each time..unfortunately I had a electrical problem to go to tonite… buss bar burnout on a 6-meter panel in one of our trailer parks… ever get to work on a hot system with unlimited amps? melted wires everywhere. One mistake and an arc so bright you cant see for 10 seconds… sure makes this omc engine job seem like tapioca pudding.

Actually the Sunbird sizzler is gorgeous. I paid 900 for the sizzler, 115hp motor, and trailer, all papers, then $300 for the Donor 140hp+boat+trailer

sold the 140electric transom for $200, gave the 2nd boat away, tossed the cowling (did TRY to sell that tho..no luck)

Sold the 115hp for $400something to an acquaintance (after stealing the power packs off it that is!)

sold the redplug controls for 200,.. ish?

Donor boat trailer brought about $350i plan to get $2500 or so for this 97 Sunbird when its running again some day. I think it would run in the Mighty Mohawk/Hudson right now if it werent for the water issue.

August 28, 2020 at 7:52 am #212902What is a 140electric transom?? Is that the rest of the old 140hp after you removed the powerhead? OK, seems like you don’t have much into this project except your time and frustration. The newer 115 turbo jet powerhead only has one powerpack, but that won’t fit/work on your older 140hp which does use two powerpacks.

Didn’t realize the puller holes don’t go all the way through the flywheel, keep spraying WD40 on the plastic bushing. Glad you didn’t have a big fire or weld yourself to one of those panels.August 28, 2020 at 3:52 pm #212941August 28, 2020 at 5:24 pm #212947I think you are referring to all four coils, not powerpacks. This is just a terminology issue… I’m guessing that “brain box” equals “powerpack”, and “powerpacks” equal “coils”. Both engines have four coils, the 78 140 has two powerpacks, one on either side of the engine. The turbo jet powerhead has only one powerpack mounted on top of the engine.

And yes, the throttle linkage is completely different between the two engines.

That transom assembly with the power trim unit looks to be in nice shape, must have been a fresh water unit….August 28, 2020 at 6:04 pm #212953ok i have the engine out.. the plate has been repaired before. im not sure if it’s a failed repair or it re-froze.. regardless I have to get it tig welded back together.

I would do it myself but I’m only AWS certified to weld 6011/7018.in the meantime I’m looking for that leak near the thermostats, and it seems to have disapeared at the moment! ack!

now…. I put pressurized water in the water inlet, i can get the engine to fill (it seems) but I cannot get any water to come out the exhaust?.. is the ONLY way for water to get out thru the thermostats??? I guess that would kinda make some sense.. but if the thermostats fail shut the engine is toast.. not so sure that’s so smart.

August 28, 2020 at 6:09 pm #212957additional pics

August 28, 2020 at 7:43 pm #212963The thermostats have small relief holes in them, so some water always can flow through them…Also, there are two pressure relief valves in there that I’m sure would pop off their seats with pressure from a garden hose…So, if no water passes through the system, something is plugged up….Perhaps the cooling passages in the housing are plugged with sand from being beached or something like that….

How about pulling the hoses off the thermostats and retesting to see if water exits the heads….August 28, 2020 at 7:50 pm #212964ok.I cannot get the slightest bit of water out of the exhaust port. I can produce about 7psi with just my mouth (9psi of hot air if you ask my girlfriend) and nothing out of the exhaust.

I pulled the little L-hoses to the thermostat and then i can push air/water out of the bottom of the cyl cooling jacket.. but here’s where it gets weird.

if I blow into the little thermostat pipe it comes back out the cylinder hole (yes it does)… and vice versa… That is just WEIRD

I put a heat gun on the thermostat and still get zero water coming out the exhaust …

lost on this one.

also I’ll need a new trigger strategy.. Ive worked the stator over 3400 times and it’s really not getting any better. I noticed there are little copper wires on the other side.. I doubt they can take that kind of repetitive abuse and not break.

I’ll get a picture of the flywheel puller I do have and see if it’s going to work.

August 29, 2020 at 10:16 am #213006I am assuming that when you blow through one of the thermostat pipes/hoses, the other hose is still connected to the other head. If so, what you describe makes sense. The water can not get out its intended exit through the unit, so it just sneaks out of the other thermostat hose, re enters the other head, and exits through the opposite open head…

I think you need to concentrate on the thermostat housing and where the water is supposed to exit from that adapter housing(s). I am not familiar with the actual cooling flow through the turbo jet unit, but it shouldn’t be hard to figure out with the engine/adapter out of the boat. I’m guessing the passages in that adapter housing are full of sand.

Not sure what you have for a flywheel puller, but I wouldn’t chance using it, unless it is the OMC puller and proper hardware. I’m sure you have some friends at local repair shops, they probably have the OMC puller. I would just put the engine in the truck, take it to one of your friends, he will pop that flywheel off in a minute or two….August 29, 2020 at 3:26 pm #213033Pictures of thermostat.. unit seems basically clean.

The purple springs appear to be some sort of safety release in case the water pressure exceeds 1.21 jiggiawatts.

this design is less than desirable. water cannot get into the engine without the air being displaced. the thermostats have no pinholes in them whatsoever to let any water thru.

the only way I see this motor filling with water is if the air escapes, and they only place i see the air escaping is thru the one little tiny hole shown by the red arrow in the picture. the hole’s placement is an additional problem because water is much heavier than air, so if any water did make it’s way down to the this hole in the thermostat, then it would leave before the air. (since this little hole is at the lowest level).

to me this design spells Engine failure by overheating as I don’t see how the motor could properly consistently fill with water.

perhaps there’s some fancy passageways going on inside the motor to compensate for this problem?

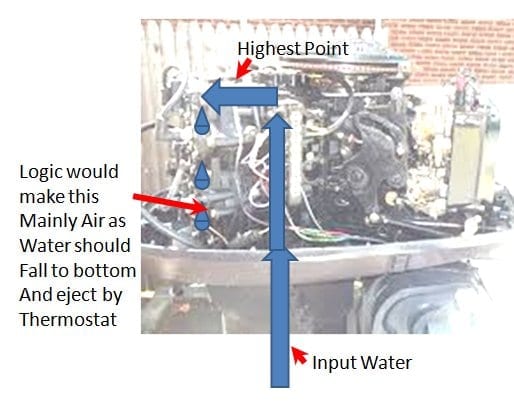

I created a quick picture of how physics would dictate water flow of a generic omc engine.. but since these omc motors tend to run and not self destruct, there must be more to the story..

-

AuthorPosts

- You must be logged in to reply to this topic.