Home › Forum › Ask A Member › Help with 65′ Evinrude Fisherman 6HP

- This topic has 94 replies, 16 voices, and was last updated 7 years, 4 months ago by

bakercheese.

-

AuthorPosts

-

March 2, 2018 at 9:05 pm #71852quote outbdnut2:Just to be sure you have checked everything, swap the condensers and see if the spark moves to the other cylinder.

I’ve seen a lot of spark plug wires measure “open” that still work – usually due to the spark plug connector on the end of the wire being not quite connected right to the wire, but spark voltage usually will jump to it anyway if the gap isn’t too big, but ohmmeter reads open. – same can happen where the other end of the wire goes into the coil.

DaveThanks Dave I appreciate it a lot when I put it all back together I’ll try switching them for giggles but they’re both new too, I think I must have done something else wrong or something rather along the line

March 2, 2018 at 9:19 pm #71853ok, gotta admit that I’m confused also…Two sets of coils, kinda hard to keep up with your resistance readings…

So, did similar coils give similar readings? What was wrong with the original coils? Sorry for not following along more closely…

OEM coil resistance specs have changed so much over the years, it is hard to know just what the right spec is. Once you throw in outside vendors, well the possibilities expand even more….March 2, 2018 at 10:06 pm #71854March 2, 2018 at 10:18 pm #71859quote fleetwin:ok, gotta admit that I’m confused also…Two sets of coils, kinda hard to keep up with your resistance readings…

So, did similar coils give similar readings? What was wrong with the original coils? Sorry for not following along more closely…

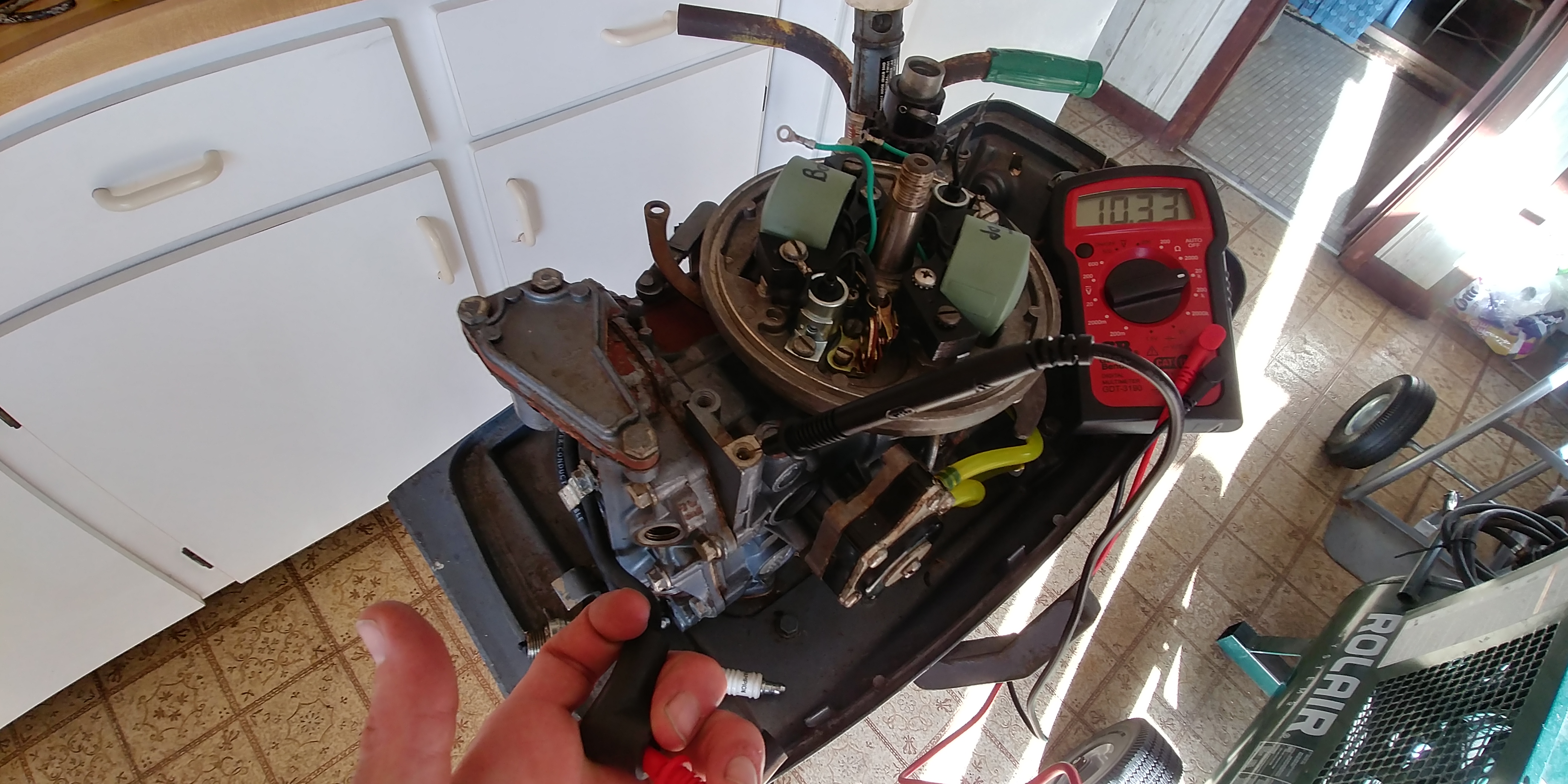

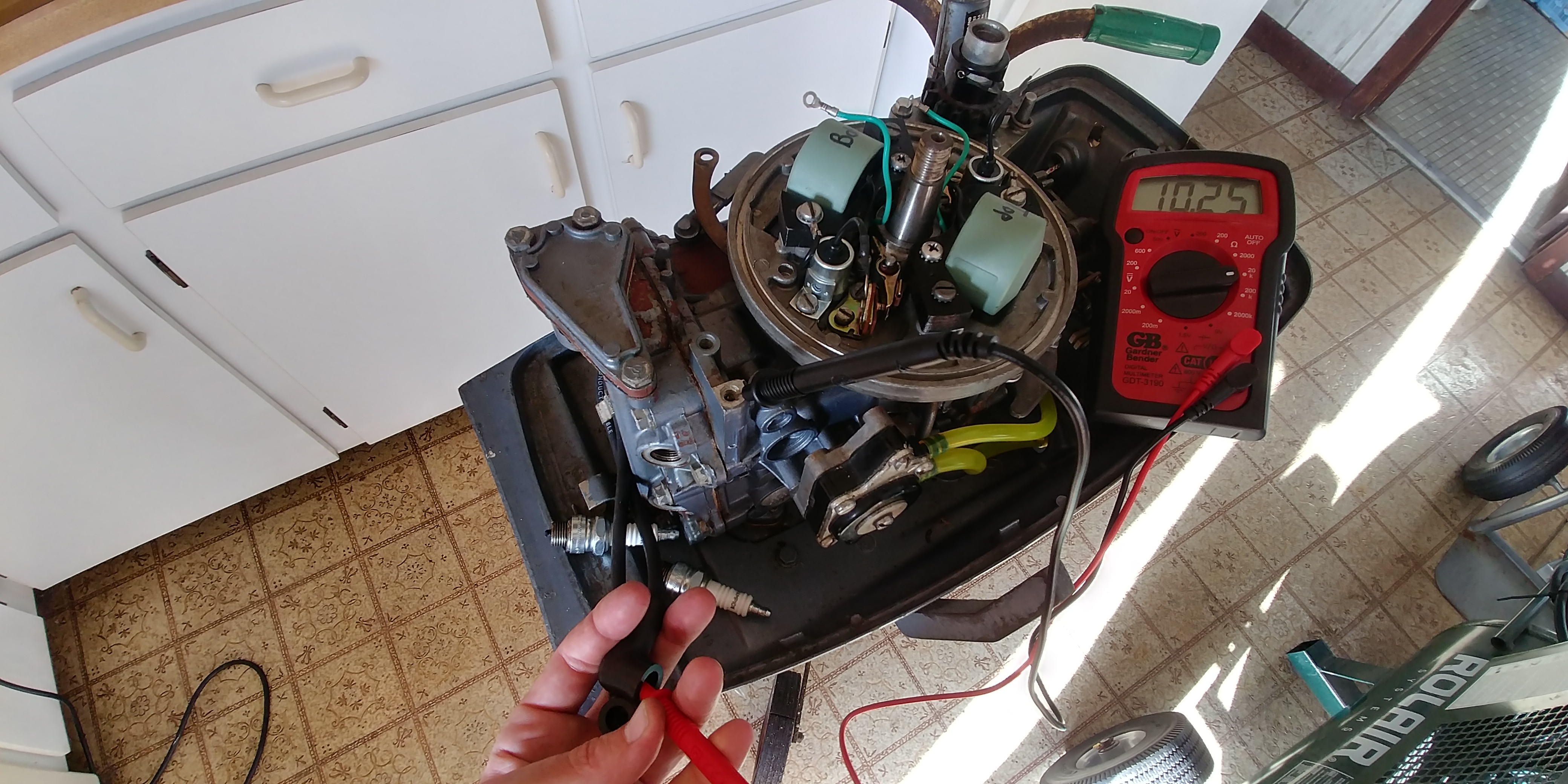

OEM coil resistance specs have changed so much over the years, it is hard to know just what the right spec is. Once you throw in outside vendors, well the possibilities expand even more….Sorry for the confusion, if you had been you’d probably be more confused hahaha it’s starting to hurt my head so trust me I’m in the same boat but I think I’ve got a grasp on it since crosbyman and everyone else have been so helpful! Now to sum it up as best I can, my readings have been hard to keep up with because I was performing them wrong at first, using the right method and test but on the wrong ohm setting all along 😳 I THOUGHT the old ones were shot because I had preformed the test on them wrong! Old coils gave similar readings in the 6’s I think and new coils tested around 10.3 ohms.

March 3, 2018 at 12:38 am #7187010.3 KILO ohms not ohms…. sound a bit high but at least they have continutiy

you should read about same value to engine body (bare metal to booth clip end… ) reconnect everything and adjust the points and CLEAN WITH a business card and acetone carb cleaner.

DO NOT INSTALL THE PLUGS… just clip some fat automotive alligator clips over them and ground both of them out on the engine frame

Spin the flywheel and check for snappy sparks on both plugs if ok … install plugs & go fishing 🙂

Joining AOMCI has priviledges 🙂

March 3, 2018 at 2:07 am #71878I can’t believe you have two bad coils. Are the points and condensers BRP or aftermarket?? I suspect your digital meter is making you chase your tail… it is difficult to get a good connection on the secondary high tension lead (AKA the spring connector inside the spark plug boot. Have you tried an Ohm’s test from the green wire on the primary winding to the secondary post of the coil? Put the coils back in, use the locating ring when installing. Try using a .020 feeler gauge to set each point assembly. Watch the cam as you rotate the crankshaft… when it opens to the widest point, stop and set the points. Reading a feeler gauge correctly comes with experience, but the .020 feeler should slide through the open points with a SLIGHT drag, but not cause the points to open, even another .001 . Take your time. Make sure the screw with the wavy washer underneath it is snugged down after setting the points. Now do the other side. Last, go back and recheck each set again… .020 feeler gauge with a slight drag is correct. If done correctly, that motor will purr like a kitten. The feeler gauge method is a simple time tested method. To check spark, set the flywheel back on and finger tighten the flywheel nut.. no need to torque at this point, just to check for spark. Good luck on your motor! Hang in there.

Forgot to mention, I didn’t see what you have been using for a spark tester? You need an open air gap tester with a 1/4 inch air gap. Neon light testers are inaccurate and will not work. An old spark plug, with the gap opened up will work in a pinch.March 3, 2018 at 2:44 am #71881OK, so at this point is it safe for me to conclude that no problems were found with the resistance readings on the coils….Yes, I know, just cuz the resistance specs are OK, does not mean the coil will fire correctly or is not arcing to ground somewhere….

Again, I see a few sets of coils there. Why was the first set of coils replaced? Did the engine have the same spark problem before and after doing all this work?

Don’t mean to repeat myself, and perhaps others have mentioned this, but there have been reports about new coils (not OEM) having laminations that are not manufactured correctly making it impossible to set the lamination air gap properly. I see you have a coil locating tool there, which is great. Simply place the coil into the locating tool to see if the laminations fit properly against the locating tool.March 3, 2018 at 4:31 am #71891from reading the maze of words it seems all coils are ok.. continuity wise anyway one set at around 6 kohms and a new pair at 10.3 kohms…

he is using the FR tool so points should just begin to open a TDC… no need to worry much about .020 gaps anymoretrue could still be bad coil but out of 4….. 2 should… work

the initial coils got replaced due to the wrong scale used on the VOM scale which was set at…. 2000 ohms

my readings have been hard to keep up with because I was performing them wrong at first, using the right method and test but on the wrong ohm setting all alongJoining AOMCI has priviledges 🙂

March 3, 2018 at 12:41 pm #71896quote crosbyman:from reading the maze of words it seems all coils are ok.. continuity wise anyway one set at around 6 kohms and a new pair at 103 kohms…

he is using the FR tool so points should just begin to open a TDC… no need to worry much about .020 gaps anymoretrue could still be bad coil but out of 4….. 2 should… work

the initial coils got replaced due to the wrong scale used on the VOM scale which was set at…. 2000 ohms

my readings have been hard to keep up with because I was performing them wrong at first, using the right method and test but on the wrong ohm setting all alongI wonder sometimes if auto ranging digital meters and timing pointer tools are too confusing for the novice? (No offense to T. Bell) Some people just want to get grandpa’s fishing motor running again, so I think we should keep it simple.. gap em at .020 and go with it. Just my opinion, respectfully.

March 3, 2018 at 1:51 pm #71901i agree but he already purchased his FR timing tool from RW …may as well use it….for awarm feeling if anything

"timing" was a bit scary for me when I got a free QD 15 years ago from a work buddy … and I used the .020 feeler gauge , moved to the VOM method after watching a utbe and now i’ll be using the "VOM/ timing tool" .. I am sure T.Bell will work it out like we all did.

Meter wise… I prefer quick reacting needles myself and was raised on the universal Telco Ks meter (solid as a rock (with a nice case)

https://picclick.ca/Bell-Systems-KS-145 … 74750.html

Joining AOMCI has priviledges 🙂

-

AuthorPosts

- You must be logged in to reply to this topic.