-

Search Results

-

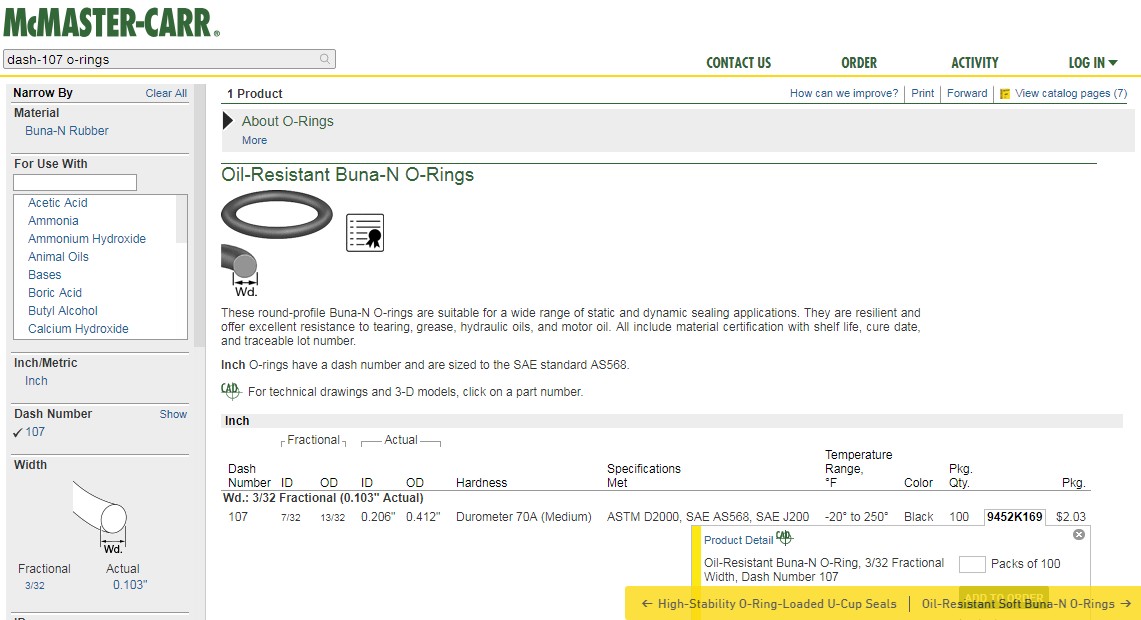

At the last meet, I purchased a batch of dual fuel line connectors to practice rebuilding and to have on hand. I have Richards Aluminum rebuild fixture and pushed out the spring, valve, washer,and front brass retainer. I already have the McMaster Carr o rings from an old topic in the past. I have 7 to rebuild all needing different parts.

Water appears to have gotten into either the air or fuel side which has oxidized or rusted apart the springs. I want to replace with new springs but need at least 14 for these but would like more for the connectors on my current tanks. The outboard sites want $5 per spring if I remember correctly. Does anybody have A McMaster Carr less costly replacement spring PN that works. I would rather purchase 25 at $25 if possible to save money as well as have them on hand?

Am also looking for 3 or 4 reasonably priced brass retainers and 1 or two valves.

After removing the connectors inside parts and ultrasonic cleaning the connector housing in Pine Sol, I noticed that some of them have in the smaller middle spring cavity a roughness of pits or possibly hardened fuel mixture. Even after cleaning again. I assume it should smooth. I thought about gently scraping or lightly sanding (600 grit) the spring cavity. Is there a downside to doing this.

Also when I used Richards fixture on my other connectors ( retainer,washer, valve ) they pushed out with little or no effort and fell into the drilled cavity below with the connector looking evenly spaced on the fixture. These 7 connectors insides were hard to push out with multiple blows. I had to pivot / rotate the connector 1/8 inch to exactly align the retainer over the cavity so as not to be on the top aluminum surface Stopping removal. I then had to rotate as much on the other side of the connector for the other side.Has anybody had this alignment issue before? Did the connector casting tolerance vary that from suppliers OMC used?

Any feedback is appreciated.

I am restoring an Evinrude Cruise a day 6 gal fuel tank. I have replaced the o-rings in the connector, replaced the dual fuel line, replaced the gasket on the tank itself, and put in a new diaphragm. The original diaphragm had a hole for the plunger, the new one did not so I punched a hole in it. When I pump it up, I get no pressure build up. I removed the mechanism several time to make sure everything is in correctly. Best I can tell, everything is in correctly.

What I was wondering is, are the diaphragms with the hole in them different than the one without a hole? Are they interchangeable or not?

Or, could there be another reason why a tank would not develop pressure?Topic: O-Rings and Expansion Plugs

I’ve been searching for sources to buy individual O-rings and expansion plugs

online, and found these sites. The later is for "carburetor sized" expansion plugs.

I ordered some O-rings for .06 cents a piece. Little 3/8" expansion plugs

that I was looking for that "others" wanted $6.95 for, they have for .97 cents

a piece if you buy 5 or more.

Of course, shipping cost inflates these prices, but if you buy enough at

a time, it brings down your cost per item pretty reasonable.http://www.carburetor-parts.com/search. … rch=search

http://www.theoringstore.com/I still haven’t learned of the size of the little o-rings in the OMC single

line tank assembly. May tear an old assembly apart and see if I can measure.What size o-ring is in the single line connectors, and do they come apart

like the dual line connectors?

Thanks.Prepare to be boarded!