Home › Forum › Ask A Member › 1930 Johnson V-45 Crank Bearings

- This topic has 20 replies, 6 voices, and was last updated 2 years, 7 months ago by

Buccaneer.

Buccaneer.

-

AuthorPosts

-

October 11, 2022 at 11:54 am #267483

Powerhead on this project is laying on the workbench, awaiting my

decision on how far to proceed.

I know at least one of the compression relief valves are leaking through,

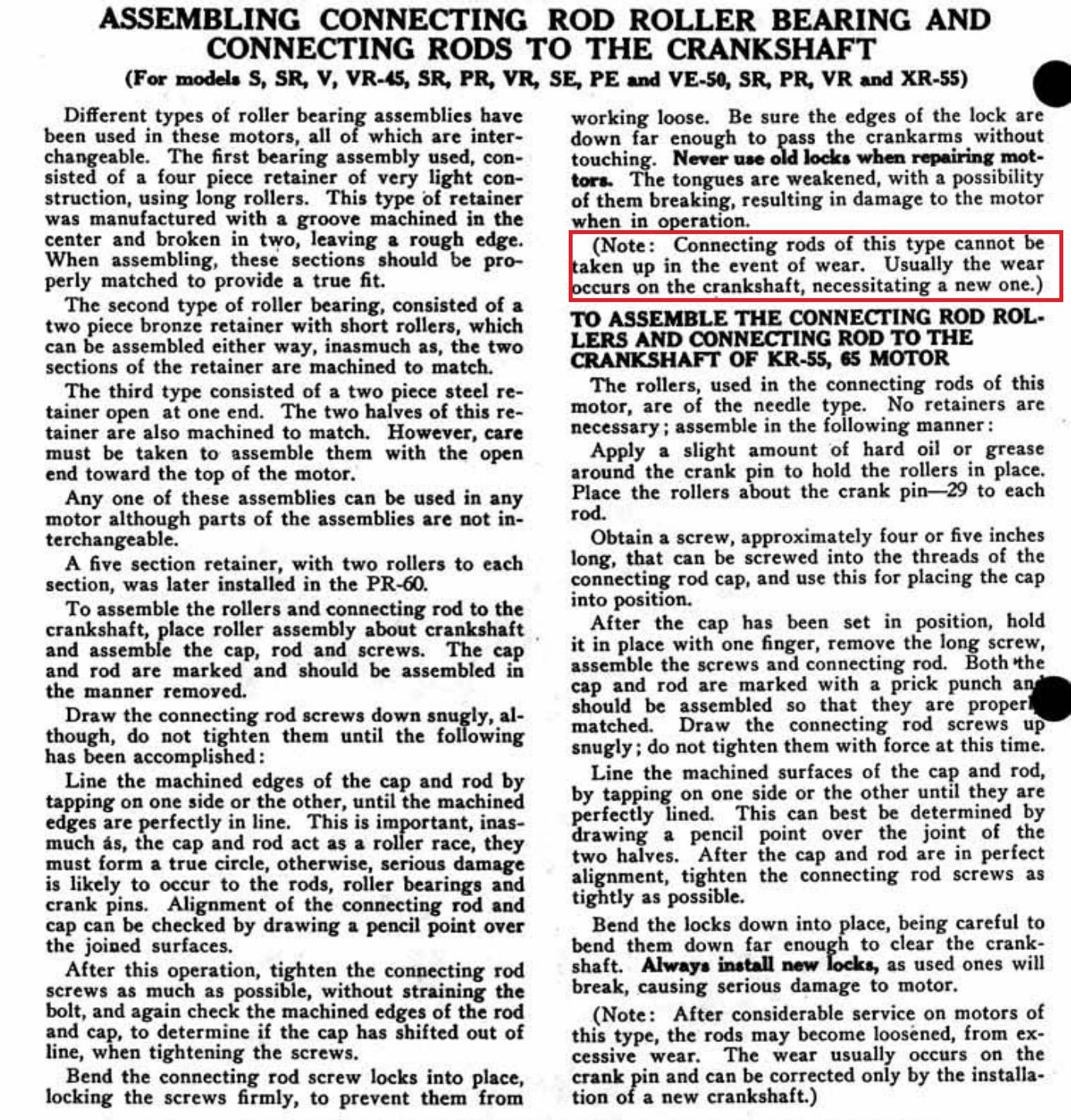

so that needs addressed.After reading the page below in the service manual, where it mentions

three different types of roller bearing cage assemblies were used

in these motors, and that the wear usually occurs in the crankshaft,

and must be replaced if worn………I’m not too hopeful about parts availability of just the roller bearings,

let alone of a new crankshaft.

Unless I find an obvious amount of rod bearing wear, would you

just leave “Well enough Alone” and not tear into the crankcase?90% of my motors go for a boat ride or two, and back on the rack for

eternity……. especially one this heavy!Prepare to be boarded!

October 11, 2022 at 12:59 pm #267488I see the rod and cap are machined for alignment purposes as is done on later motors. You’re probably aware, but it’s always a good idea to check and record for future reference which surfaces are lined up on each assembly before taking them apart. This step is really important on later motors using rods which have been fractured. Sometimes, if the rod/cap have four machined surfaces, only three of them will be in perfect alignment with one of them having a bit of overhang. Reassembling them with the same surfaces in alignment will ensure the inner bearing surfaces are perfectly aligned. Here’s where a sharp dental pick comes in handy.

October 11, 2022 at 3:38 pm #267502Mumbles, I always mark the rod caps, if not done already, before taking them

apart, so I don’t get them on 180 out of whack.

The manual seems to suggest that the rod and cap mate perfectly for the sake

of the roller bearings inside.

Haven’t decided yet if I’m tearing into the rod bearings.

Right now, trying to get the port head off so I can inspect the compression relief valves.

Thanks for the heads up!Prepare to be boarded!

October 12, 2022 at 7:17 am #267522Those bearing cages and rollers were used on a bunch of early Jonson engines.I replaced the rollers on a S45 and had no problem finding new ones.

October 12, 2022 at 8:58 am #267524Those bearing cages and rollers were used on a bunch of early Jonson engines.I replaced the rollers on a S45 and had no problem finding new ones.

Stanley, are you saying you found brand new rollers to put in the old cages,

or replaced the bearings assemblies from another motor?The part that worries me, as stated in the manual, is that most of the

wear will take place on the crankshaft, instead of the bearing rollers.

Thanks.Prepare to be boarded!

October 12, 2022 at 2:36 pm #267532I used new rollers and cages.The crankshafts wear and there is not much you can do about that without finding a better one.But the cages and rollers also wear and those can be replaced.So,back to your original question,if it’s going to keep you from sleeping at night,tear it down and check the crank.

October 12, 2022 at 2:46 pm #267533I used new rollers and cages.The crankshafts wear and there is not much you can do about that without finding a better one.But the cages and rollers also wear and those can be replaced.So,back to your original question,if it’s going to keep you from sleeping at night,tear it down and check the crank.

Thanks Stanley, no idea how you found new bearings for a 90 yr old

antique, but I’ll look up the parts numbers tonight for kicks!Prepare to be boarded!

October 12, 2022 at 4:30 pm #267537Search the roller dimensions.I’m pretty sure the rollers and cages I found were actually listed as Harley Davidson parts.

October 12, 2022 at 5:39 pm #267538Search the roller dimensions.I’m pretty sure the rollers and cages I found were actually listed as Harley Davidson parts.

Interesting about Harley Davidson parts!

Being that Johnson used three different size / style bearings and cages,

it’s going to be hard to research what size I would need, unless I

take it all apart first. I’m on day two and still trying to get the port head off!Prepare to be boarded!

October 17, 2022 at 5:43 pm #267798OK,–So, there were several variations of cages and roller length. There were the bronze (Harley Davidson) type that used the short rollers, and the streel cages that used the longer rollers, both of which are available. The problem with the crank came from the short rollers and that they ran them loose. That, coupled with over-propped, made the engine lug and it beat the crank causing a groove in the center of the crankpin. The short rollers with the bronze, thick cages, didn’t allow the roller to cover the full area of the crankpin.

Bill Salisbury is the one who studied all this and had oversized (larger diameter) rollers made. He would then assemble a rod in incremental stages to the point the rod would get tight, then back of in sizes so there was free movement. Sometimes it required different sized rollers per crankpin.

Chances are, if your motor has the longer rollers, that the crank is OK. If so try increasing the roller diameter .005 and see how it feels. I can tell you all the S/V engines I’ve done needed oversized rollers, and when you got it right, that motor would be smooth! Once finished, check rpm”s and if it isn’t reaching full rpm’s, go to less prop.

I think those engines got a bad rap simply because they were over-propped from the factory for light boats and were used on heavier boats.

George

-

AuthorPosts

- You must be logged in to reply to this topic.