Home › Forum › Ask A Member › 1949 TD 20 low speed jet question

- This topic has 16 replies, 10 voices, and was last updated 2 years, 7 months ago by

Mwohlenhaus.

-

AuthorPosts

-

September 21, 2022 at 10:03 am #266415

I have been scouring the pages of this forum for about a month since I acquired a 1949 TD 20 in rough shape cosmetically. I was at the local dump and always check out the metal bin. I saw a prop sticking out of the pile and dug a bit to find the rest of the motor apparently intact. Due to it having other stuff on top of it the gas tank is a bit dented and scratched and the recoil rope was wrapped around the motor fully extended. The paint and decals are in rough shape. I brought it home and put some fuel in it, and tried to fire it up, no go. When I turned the fuel shut-off on it filled the bowl and started running out the overflow on the carb cap. The primer leaked when I pressed it down as well. spark was blue and strong, compression at 75 PSI +/- 1lb. The filter screen/check valve in the idle circuit of the carb was clean and check valve worked. I did a bit of research to find info about the needle, seat and float. I pulled the carb, took it apart and found it to be really clean considering it was in the dumpster. I was able to get the primer assembly out with very little struggle. I just contacted Lloyd to see if he still has primer seals available and will order them. I found that the recoil spring had broken and I haven’t decided if I will just order it or wait to see if I can get it running first (all signs point to a healthy motor). I suspect a grandkid was cleaning out grandpa’s garage, found the motor, put fuel to it and pulled until the recoil spring broke, or it broke the last time grandpa went to use it and he put it on ice for years. It did not have fuel in the tank and didn’t stink like rancid gas.

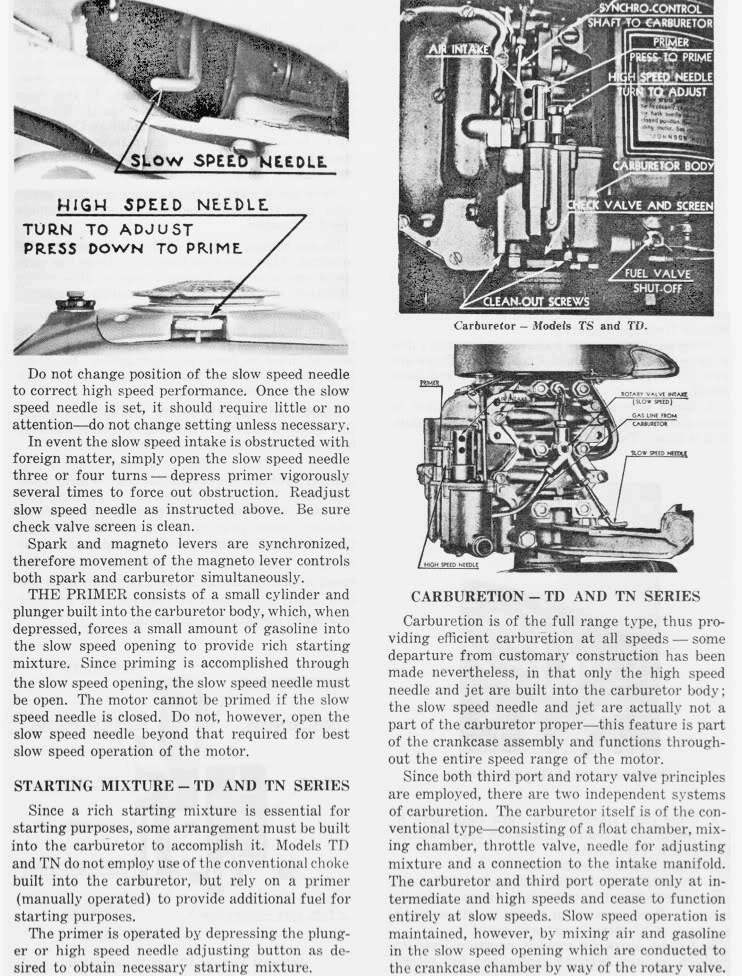

Anyway that is the history of the motor thus far. My question is this, on the low speed needle housing is that open into the crank? When I took the needle out to clean it I got looking and saw that there was a passage directly to the crankshaft. I get how it works and am intrigued that the idle circuit is separate from the carb, but is there supposed to be a baffle or something over the hole. In all reality the carb is open to the air with just the baffle on it and boat motors don’t run in dust but just having a hard time wrapping my head around it. I have read descriptions about the needle but no mention whether it is directly open to the crank.

September 21, 2022 at 10:58 am #266417Basic Carburetor Servicing Johnson H and T Series (pochefamily.org)

Joining AOMCI has priviledges 🙂

September 21, 2022 at 11:16 am #266418Nothing over the hole. Interesting thing is, if you are peering at the hole and the motor lean-sneezes, it will spit in your eye.

1 user thanked author for this post.

September 21, 2022 at 12:36 pm #266419September 21, 2022 at 3:13 pm #266422A lot of the times, the uglier those motors are, the better they run! They got beat up because somebody used them. Just run the proper oil mix when you do get it running. They aren’t 50/1 like later motors, they ran 16/1 back in the day.

September 21, 2022 at 5:30 pm #266423I have your primer seals ready to go. It should run great with 75 psi compression. Sounds like you may need to make a new float.

September 21, 2022 at 6:24 pm #266424I am going to test the float like I saw on youtube, attach fuel line and a funnel to the copper line and fill it to see if it runs over. there was some corrosion on the needle and seat that I cleaned off. Blowing into it when the float is upside down holds air back I didn’t get the rancid gas taste either! The float seemed to be intact, however blackened.

September 21, 2022 at 8:09 pm #266437Good to be back, almost died from covid & west nile virous. Check the compression first, then your capicitors if you have no fire. Like Lloyd spoke of 75 compression is good. Won’t idle with low compression. Please check the lower unit for a good waterpump & oil in the gears. Nice find too. The plug wires can be replaced but be VERY CAREFUL with too much heat, it will destroy the coil. I did desroy one before I learned how to keep the heat down on the coil terminal. Never put the heat on the terminal heat from the top of the wire & get off fast!!

Good Luck

Jeff

September 22, 2022 at 8:31 am #266446The fuel overflow is most likely caused by the brass float pin sticking within it’s passage. A float in poor condition adds to the problem. Polish the float pin, clean the seat, fabricate a new float, coat the float with dollar store super glue, let the super glue cure for a week or more, and install the float to the correct height on the float pin using the groove and clip.

The sticking problem can sometimes fix itself by running the motor for a period of time. The vibration from running and the motion of the float helps loosen any crud that is contributing to the sticking float problem.

Improvise-Adapt-Overcome

September 22, 2022 at 10:02 am #266453Thank you guys for all the replies. Fortunately, I did not get Covid as bad as you Jeff! My symptoms hung on for about a month with shortness of breath and tiring easily, but no taste or smell difference.

I learned a valuable lesson not so long ago with motors… Before tearing carb apart, put fuel to the motor and see if it runs, no need to fix a problem that isn’t.

-

AuthorPosts

- You must be logged in to reply to this topic.