Home › Forum › Ask A Member › 1953 Johnson Seahorse 25 hp RD-15 not pumping water

- This topic has 25 replies, 6 voices, and was last updated 4 years, 1 month ago by

labrador-guy.

labrador-guy.

-

AuthorPosts

-

May 1, 2019 at 8:38 pm #174646

Here are a couple pictures. I have a ’51 and a ’53 big twin. There is one rubber grommet that seals the up water tube from the exhaust housing. #302636 That might be your problem. The upper end of the water tube has a ferral or flared end that attaches to the small housing between the power head and the exhaust housing. I sealed both of mine up with yamabond last summer and they pump great. The water pump pushes water from two cavities to the back of the exhaust housing where the up water tube hangs. These motors are fun to run but a bugger to crank for an old guy!

dale

sorry can’t post pics today

-

This reply was modified 5 years ago by

labrador-guy.

labrador-guy.

March 6, 2020 at 5:39 pm #196838Still working on the water issue. Found the channels were worn unevenly so I filed the exhaust case and lower unit water channels so they are flat again. Found that when i was lifting lower unit into exhaust case at a steep angle the driveshaft was springing upward and possibly displacing the pin from the impeller groove and then pressing down on impeller and spinning on top of it once running. I will try to install it straight up instead of an angle to start…

I also saw that the driveshaft has scoring where it was rubbing on the oil retainer. There is also lots of play and a gap at the top of the housing around driveshaft. I wonder if a new oil retainer would be a good idea and if there was supposed to be an o ring at the driveshaft inlet of housing like the 54 models need. I currently have water housing number 302613 installed on the lower unit.

I did not try flipping the plate over so the convex side is up. It was flat when I unpacked it from NOS.

I don’t understand why it would be convex towards impeller. I guess I’ll look for an entire water pump repair kit, water tube grommet and a new oil retainer bushing to start off.

Any suggestions are greatly appreciated.March 6, 2020 at 6:59 pm #196840Methinks you are over thinking this. Once the pump is assembled over the drive shaft, it is impossible for the pin to get out, no matter what angle you are holding it. SOME pump plates are slightly convex , some are not You say your NOS was flat, so lets say that is normal. Now, if the pin is touching the plate, something is wrong. Possibly wrong drive shaft. Or possibly the drive shaft support in the gearcase is missing. Either way, you are wasting time and money till it is corrected.

If the original water tube grommet is in there and not rotted away, that part is ok.

No, the water pump housing does not seal to the shaft, except by the fit between the impeller and plate and the fit between the impeller and pump housing, at the drive shaft area. That is why the plate cannot be bent downward

No gasket was needed, nor provided

Finally, I gotta ask–where are you running this thing? It won’t work in a 5 gallon bucket.

Get back with us if it still doesn’t work after fixing the drive shaft pin position issue.

March 6, 2020 at 10:43 pm #196854Thanks for advice! I was testing it in a Johnson service tank. Water was up past screen and over side inlet holes. It looked like there should have been plenty water height but maybe since it’s a short shaft it didn’t have enough water submersion? I don’t think I can use muffs on this model either…

Since the driveshaft doesn’t have a part number stamped on it, how should I verify it’s the correct one without ordering a new one?

The driveshaft seems like it’s sitting on a spring at certain times and it will float up and down freely most of time when disassembled in a springy action. I will take gear case apart if I need to so I can make sure the support is present and not damaged.

I posted a classified for a new water pump kit so that I can have additional parts for comparison and replacement since the plate and housing seem to have been through hell.Thank you Sir!

March 7, 2020 at 3:19 am #1968561. The water pump should be submerged under water before starting the motor. It is a good water pump, but a lousy air pump and lousy at lifting water up to it.

2. The “springy” feel is air pressure inside the gearcase, caused by plunging the drive shaft in like a piston. Loosening the oil level plug will let the air pressure out.

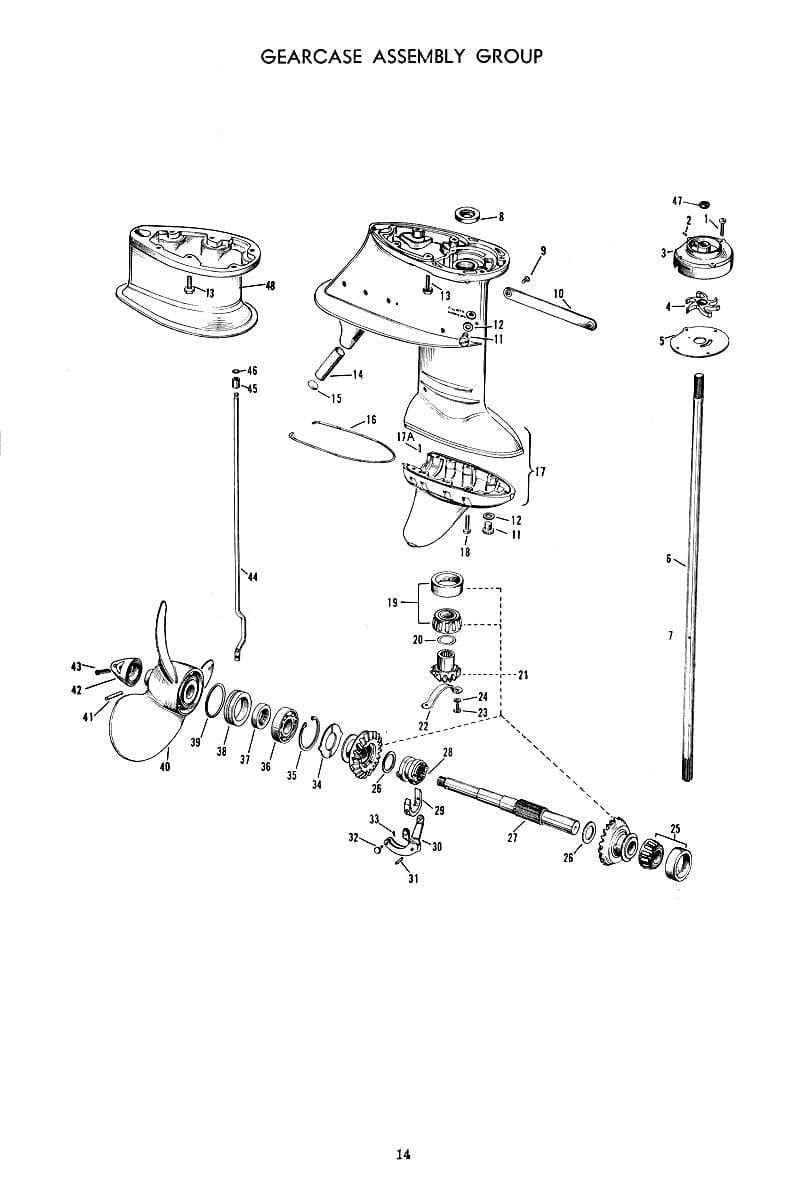

3. As for being the correct drive shaft, that’s a good question. Of course comparing with a known correct one is one way, but an expensive way if you have to buy one. I’d say dump the oil out and use a flashlight to see if you can see the support down in there (#22 in the diagram). It is a curved piece of metal strap, arching upward, and the shaft rests on it. If the support is in there and the impeller pin is not higher than the pump plate, I’d say it just about has to be the wrong shaft.

4. To my knowledge, they never made a pump “kit” for that motor. You had to buy individual parts.

March 7, 2020 at 10:42 am #196876I have no experience with this model, but a few things concern me….. First, like Frank says, that impeller key should not be able to “fall out of place” once the impeller housing is properly installed. So, if the key is falling out, something else is wrong. The other thing that concerns me is that you are talking about flipping the SS impeller plate upside down on the gearcase. There is only one way that SS plate will work properly, and I have never seen an OMC that has symmetric screw holes in the plate, so it seems almost impossible to successfully install the SS plate upside down. But again, I have never had any experience with this particular model…

From what I have read, it seems like you got this engine with the cooling problem, so it is not something you did….I’m guessing there is a mismatch of parts also….Hopefully Frank or someone will chime in to confirm whether or not the SS plate can be inadvertently flipped upside down on this engine….March 7, 2020 at 10:53 am #196879I don’t have one in front of me, but I would say it is highly unlikely to be flippable.

March 9, 2020 at 8:18 am #197008I think you’re right about not being able to flip the plate. I have a 54 And up service manual that doesn’t include the 53. It seems like everything is the same or very similar. I did acquire this motor with the known pumping problem. So can anyone confirm if I need a water tube grommet on the 53 motor? There has been conflicting trains of thought on this for the 53. I see the 54 has one. I also see that the water pump housing is a bit different on the 54 while part hunting.

I will dump gear oil and inspect case for support bracket. Once that is verified should I make another convexity in plate or leave flat (as we hammered it flat after it was pushed by impeller malfunction)? Gonna call Ed Elliot for replacement parts for overhaul in the meantime.Wondering if this motor has to be tested while fully submerged in the lake as opposed to a service tank due to short shaft??

March 9, 2020 at 10:48 am #197030I would try to locate a proper parts list for your 1953 model first. I would definitely find a new SS impeller plate, don’t try and reuse it after you hammered it flat….

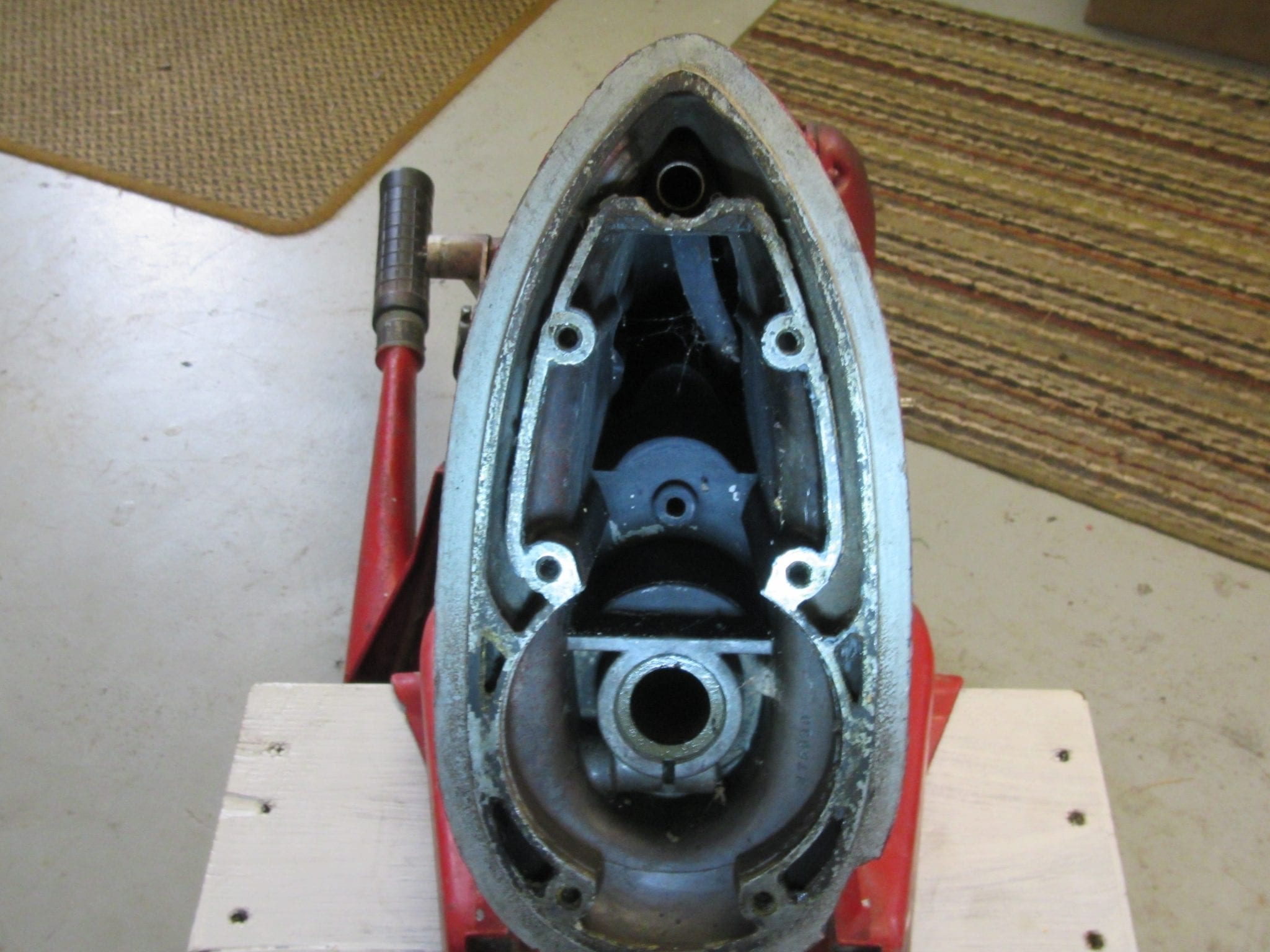

March 9, 2020 at 12:42 pm #197033Here is a picture of the exhaust housing. Looking up towards the power head. The grommet is on the water tube that you see in the top of the picture. If it is bad most of the pumped cooling water will be dumped into the exhaust. This is the first place I would check now that you know your impeller is good. Hope this helps!

dale

-

This reply was modified 5 years ago by

-

AuthorPosts

- You must be logged in to reply to this topic.