Home › Forum › Ask A Member › 1954 CD-11 Convert from 2 line to 1 line fuel

- This topic has 25 replies, 7 voices, and was last updated 2 years, 4 months ago by

drifter.

-

AuthorPosts

-

November 10, 2021 at 5:35 pm #249501

Mumbles, ty very good point about the drain hole, i didn’t think about that…..I will definitely go with the vacuum cap solution.

1 user thanked author for this post.

November 10, 2021 at 5:38 pm #249502TY bobw! I realized that would have made a big mistake Not going with the vacuum cap solution….so that is the way I will go!

-

This reply was modified 2 years, 5 months ago by

Gary Pasquale.

November 10, 2021 at 7:00 pm #249507actually .. been wrong before but… looking closely at the film there does not appear to be a drain hole at the bottom of the channels to block ?

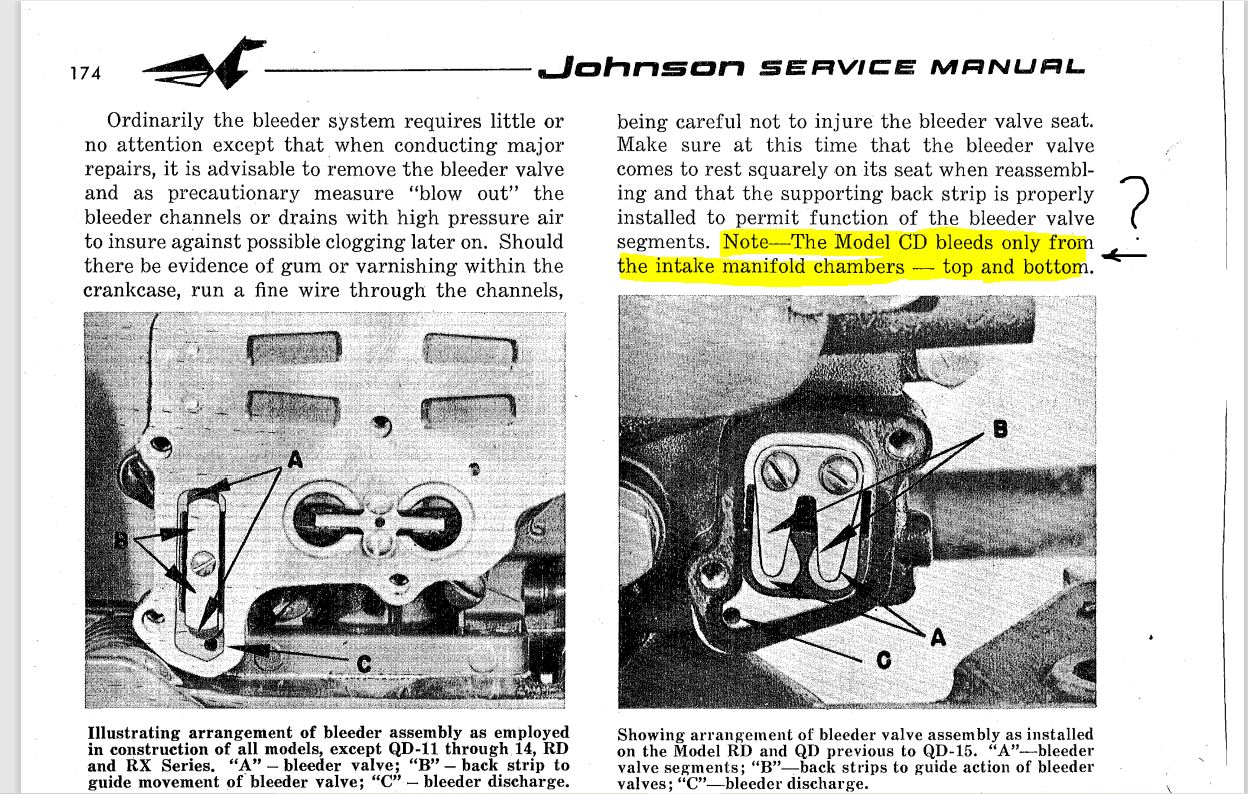

Johnson manual shows some on one PH …

I suspect main internal drainage would be out the purge valve since it is the lowest point of the crankcase where fuel would puddle anyway.

I modified my 5.5 and do not recall this concern nor did it affect the performance

I have another nice golden 5.5 to work on this winter and will be on the look out for that tiny drain.

I may need to rework the 5.5 with caps for my friendly neighbor to whom I sold the 5.5hp. He did report what was to him..abnormal fouling during trolling sessions !!!!

Joining AOMCI has priviledges 🙂

November 12, 2021 at 3:56 pm #249567I checked for drain holes in some later 5.5 or 6 horse motors I have in pieces here and could only find a drain hole in the left channel for the lower cylinder, nothing in the right channel for the upper cylinder. The left channel drain hole is connected to the lower half of the check valve and I’m not sure where the upper half connects to the top cylinder. Maybe I’ll blow some air thru it to find out if it is connected or not.

I don’t have a ’54 or ’55 block nearby but I’m sure they had puddle drain holes in both channels. If I move a bunch of stuff around I will pull one out to check.

November 12, 2021 at 5:22 pm #249579GREAT NEWS….Mumbles thanks for that close up shot !

I modified my 5.5 with the right side channel plugged with JB weld so I think I am good .

Also found this comment about CD route ?? see picture

That said I guess plugging the right sire ain’t so bad

Also, I think in a worst case scenario plugging the left drain would simply force any fuel/oil to go via the alternate route …. mainly via the the top side then internally down the bottom the crankcase

cavity to be purged out

Joining AOMCI has priviledges 🙂

-

This reply was modified 2 years, 5 months ago by

Mumbles.

Mumbles.

November 13, 2021 at 7:54 am #249594fyi

https://forums.iboats.com/threads/1954-cd-11-restoration.506115/Joining AOMCI has priviledges 🙂

November 15, 2021 at 8:34 am #249669OK, TY ALL for your advice and efforts!!!!!!!!!! Does anyone have the ID of the bleeder valves? I am looking at using this as a “block off solution” Plugs

-

This reply was modified 2 years, 5 months ago by

Gary Pasquale.

-

This reply was modified 2 years, 5 months ago by

Gary Pasquale.

November 15, 2021 at 9:42 am #249672can you clarify…?

Joining AOMCI has priviledges 🙂

November 15, 2021 at 9:45 am #249673instead of using the vacuum caps I am thinking of using the “plugs” to block the holes. I haven’t had time to open the motor and take the measurement of the size of the hole.

November 15, 2021 at 10:08 am #249674why not just fill in the right side channel with JB weld and remove the air check valve . Keep all parts and if later you want to “go original” you can just clean up the channel with a Dremel tool to restore it.

the air nipple will become your pump’s pulse line.

see link for the RD mod. the right hand channel picture from mumbles shows no drain hole at the bottom of the right channel so check your’s on the CD

https://www.aomci.org/forums/topic/gas-fuel-leak-help-on-a-1954-25hp-johnson-rd-15/

if you have no such drain hole on your rightand channel JB weld won’t hurt things anyway and the left channel will supply the pulses

up to you…

the purge valve mod is a whole diff. subject

Joining AOMCI has priviledges 🙂

-

This reply was modified 2 years, 5 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.