Home › Forum › Ask A Member › 1955 25HP Evinrude: How can I block off these ports?

- This topic has 15 replies, 10 voices, and was last updated 2 years, 8 months ago by

garry-in-michigan.

garry-in-michigan.

-

AuthorPosts

-

July 29, 2021 at 5:10 pm #243903

Interesting, I would think that the timing plate would limit that.

July 29, 2021 at 8:48 pm #243928I think describing the switch as a rev limiter is more accurate than describing it as a runaway preventer.

When a certain vacuum is reached, at high RPM, the switch closes grounding out the set of points it’s hooked up to. This kills the spark on that cylinder and the motor slows down. In an outboard motor runaway situation, the motor revs up on its own uncontrollably because of preignition and no spark is needed to keep it running. The preignition is usually caused by an air leak which leans out the mixture and raises the combustion chamber temperatures. As a result, the spark plug or a piece of carbon will become red hot which will ignite the fuel charge before its time. Turning the key off or pulling the spark plug wires off will not stop the motor as by now the ignition system is redundant and just there for the ride. Flooding the motor by choking it to death will bring it to a stop.

A runaway diesel motor is a whole different ball game. When they runaway, turning off the fuel supply has no effect as they are usually running on their own crankcase oil. A blown oil seal in a turbo will cause this and the motor will keep screaming away until it either breaks up or runs out of lube oil. Either way, it’s not good for the motor. Yeah, I know, strangling its air supply will shut it down to but diesels usually have a robust air filter system and by the time it’s removed to gain access to the intake, the damage will have been done.

July 29, 2021 at 9:21 pm #243932I think describing the switch as a rev limiter is more accurate than describing it as a runaway preventer.

When a certain vacuum is reached, at high RPM, the switch closes grounding out the set of points it’s hooked up to. This kills the spark on that cylinder and the motor slows down. In an outboard motor runaway situation, the motor revs up on its own uncontrollably because of preignition and no spark is needed to keep it running. The preignition is usually caused by an air leak which leans out the mixture and raises the combustion chamber temperatures. As a result, the spark plug or a piece of carbon will become red hot which will ignite the fuel charge before its time. Turning the key off or pulling the spark plug wires off will not stop the motor as by now the ignition system is redundant and just there for the ride. Flooding the motor by choking it to death will bring it to a stop.

A runaway diesel motor is a whole different ball game. When they runaway, turning off the fuel supply has no effect as they are usually running on their own crankcase oil. A blown oil seal in a turbo will cause this and the motor will keep screaming away until it either breaks up or runs out of lube oil. Either way, it’s not good for the motor. Yeah, I know, strangling its air supply will shut it down to but diesels usually have a robust air filter system and by the time it’s removed to gain access to the intake, the damage will have been done.

Reminds me of the time I was working on a diesel JD tractor in Vo-Tech.

Not sure what I was even suppose to do to it, or what was wrong with it,

but I was standing next to it and test started it. It started “WIDE” open.

By the time the instructor ran over, I almost had it shut down, by

holding a motors manual over the air intake……. I think the air cleaner was off!Prepare to be boarded!

July 30, 2021 at 2:34 pm #243975I say mumbles is correct—as far as it goes. The words for the situation probably are not correct. I have spent lots of time thinking and pondering over the past 60 years about exactly what is happening in an outboard motor in so-called “runaway” condition.

First, in an outboard the term generally means what happens when a motor is revved up in neutral or no-load situation, and cutting the throttle back does not slow it down. As suggested, it is not true thermal “runaway” It happens often in OMC Big-Twin and RD series motors and the sound is unmistakable when it is happening. The vacuum cut-out switch senses that condition and kills the spark on one cylinder till it slows down.

So what is causing it to run away? In my theory and opinion, it is flywheel momentum and manifold vacuum. Those motors have large and heavy flywheels for smooth running. Get the thing spinning fast and close the throttle, and abnormally high vacuum is created in the intake manifold.

Now consider the carburetor. It has the main nozzle and a large venturi. Great for high speed and lots of air flow. But slow it down and there is not enough air flow through the venturi to make it work. So a second fuel and air flow route is provided for the idle and intermediate speeds. You could compare it to a second, smaller carb. Briefly, it consists of a hole or holes in the throttle butterfly with holes in the carb body critically placed in relation to the butterfly in closed or cracked-open position. At idle, fuel and air flow through these holes are what is feeding the cylinders. The main venturi and nozzle really aren’t doing anything because of the slow air flow through that area.

So…now you create an abnormally high vacuum in the manifold. That high vacuum sucks more air in through the carburetor. Enough more air to also draw in more fuel, possibly even some from the main nozzle. Bottom line is this extra air and fuel is enough to provide the “kick” that is keeping the flywheel spinning rapidly. Killing the spark prevents the extra fuel/air from igniting, and it slows down

BTW, I also have had a couple of hair raising experiences. One was a 40hp Scott-Atwater (no vacuum cut-out switch). I had to pick up a tool and bust off a spark plug to slow it down. Worse, was a Diesel that I accidently got into true runaway. I was so panicked that I don’t truly remember how I slowed that thing down. Suffice to say to me that I shouldn’t be working on Diesels.

That’s my story and I’m sticking with it. At least till somebody corrects me.

-

This reply was modified 2 years, 8 months ago by

frankr.

frankr.

July 30, 2021 at 9:22 pm #244000Thanks Frank, that all makes sense

Joe B

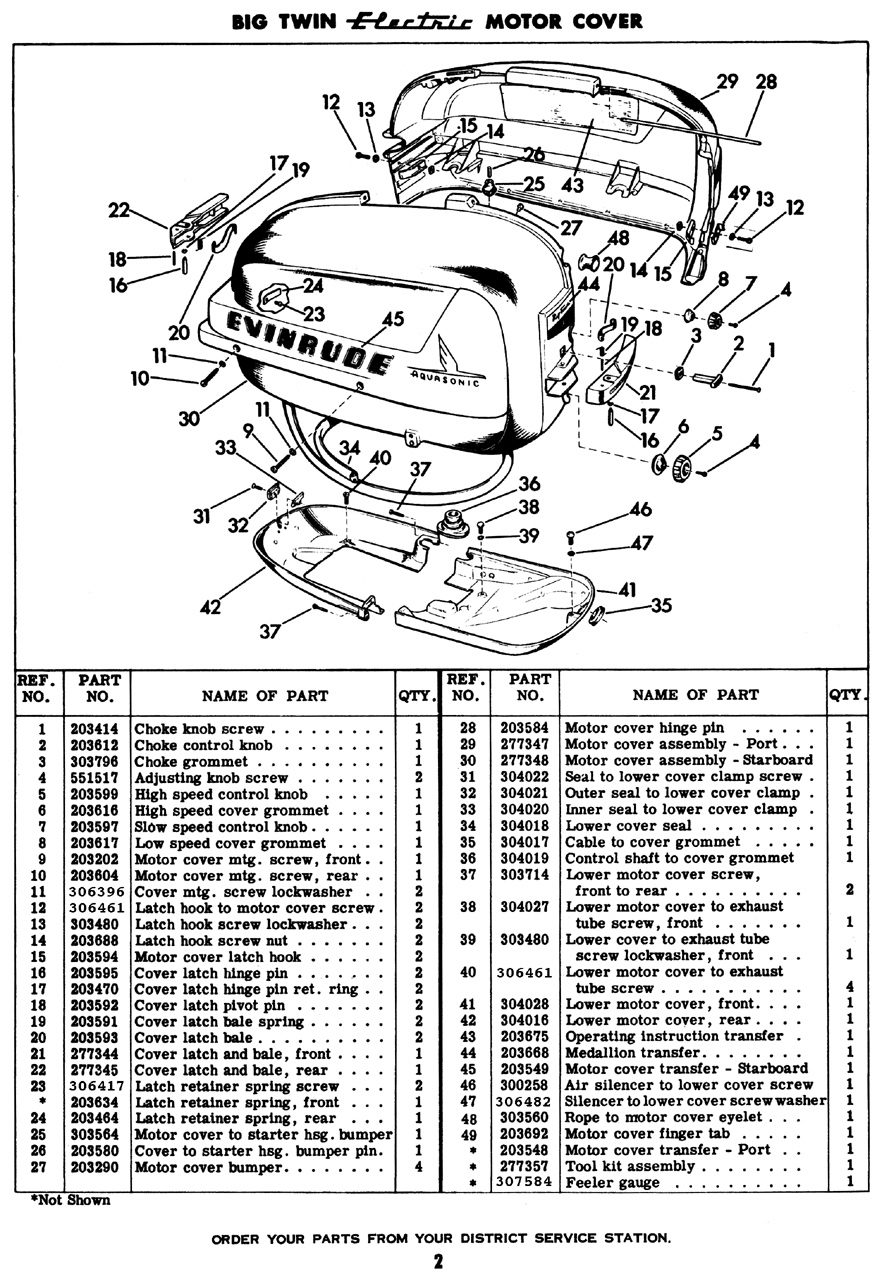

July 31, 2021 at 3:31 am #244001There were several engineering changes in that model. First run had a rubber elbow on the air intake. That was the first to go. It was found the Fiberglass silencing material could collect gas and oil residue and catch fire. That eliminated the tube (15) and fiberglass (16}. Then the quarter inch drain hole in the lower front motor cover was- enlarged to two inches for better breathing.

-

This reply was modified 2 years, 8 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.