Home › Forum › Ask A Member › 1963 Sportwin O-Ring on Upper Crank Bearing?

- This topic has 5 replies, 3 voices, and was last updated 6 years, 4 months ago by

h20lew.

h20lew.

-

AuthorPosts

-

December 23, 2017 at 3:40 pm #8887

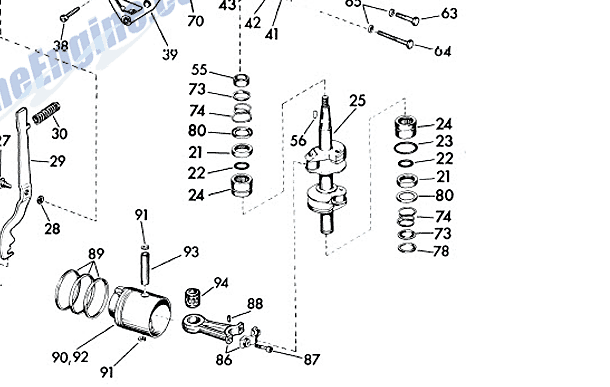

I’m about to re-assemble a 1963 Evinrude Sportwin and was curious about the o-rings. The parts list exploded diagram for this model shows OMC part number 0302035 on the lower crank bearing but not the upper one. There are similar slots for the o-ring on both the upper and lower portions of the crankcase. It seems like the same o-ring could be used at the top similar to the bottom – any reason not to? The O-ring is #23 in the attached photo clip.

December 23, 2017 at 4:34 pm #68916OK, good question indeed….

This engine may indeed use the same goofy oil return system that is on some of the FD/RD engines…Although there is a groove for the oring, please do not use one (at least for now until we have figure out your engine). Look for a vertical groove with a hole in it facing forward in the crankcase cavity where the upper bearing resides (post pictures if you are unsure). Adding the oring to a crankcase with this strange recirculation design will plug it up and actually cause oil to puddle/spray up into the mag plate….December 23, 2017 at 5:55 pm #68923Thanks so much for helping me out with this.

I’ve posted pictures, I think I have the notch in the front crankcase half that you are talking about. So I’ll NOT install the o-ring on the top.

If I could follow up with a related question on these crank bearings – On the back half there are small tubes that I’ll assume are for injecting oil into the bearings… do I line the holes in the bearings up with the tubes or do the tubes just fit anywhere in the slots on the bearings?

December 23, 2017 at 8:07 pm #68924Yes the bearings lock into position. The crank halves will not close if everything in not lined up.

December 23, 2017 at 11:02 pm #68932OK, yes, I see the notch in the front half of the crankcase, so no oring is used….Please check the vacuum/recirc passages carefully, or oil will back up into the mag plate. And yes, those locating pins must line up with/into the holes in the bearings, or parts will be crushed/distorted/damaged when the crankcase is reassembled. Those locating pins may or may not be lubricating holes, try passing a tiny wire/light through to check it out….

The hole in the upper front half of the crankcase is a vacuum port that draws residual oil down and out of the upper bearing area.

Getting back to your original question….You can see that adding the oring to the upper bearing would disable the vacuum port allowing excess oil to build up and spray into the mag plate….December 24, 2017 at 5:42 pm #68955Thanks guys for the advice. Much appreciated.

I’ve got one more re-assembly question on the connecting rods, but I’ll post that as a separate question.

-

AuthorPosts

- You must be logged in to reply to this topic.