Home › Forum › Ask A Member › 5 hp seabee

- This topic has 17 replies, 5 voices, and was last updated 5 years, 1 month ago by

Tinman.

-

AuthorPosts

-

December 19, 2018 at 6:52 pm #160749

Hi everyone, maybe have a little problem. Not sure. Have a 5 hp sea bee model # 025-3603. Dropped the lower unit the other day. This has a shift rod coupler down low so you don’t have to pull the power head. Anyway, the cup and the spring came down with the driveshaft but the rest ( I’m assuming it’s similar to a 5.5) the carbon seal, washer and gasket stayed up by the motor and is flopping around up there. Are they supposed to come out too for replacement or is it a different setup and you just get them centered and run the driveshaft back up through them into the powerhead? Thanks any input is greatly appreciated!

December 20, 2018 at 12:40 pm #160796I would strongly recommend that you pull the power head. I don’t know exactly which model you own, but the carbon seal assembly was used for many years.

The o-ring and cork washer/seal within the assembly should be replaced.

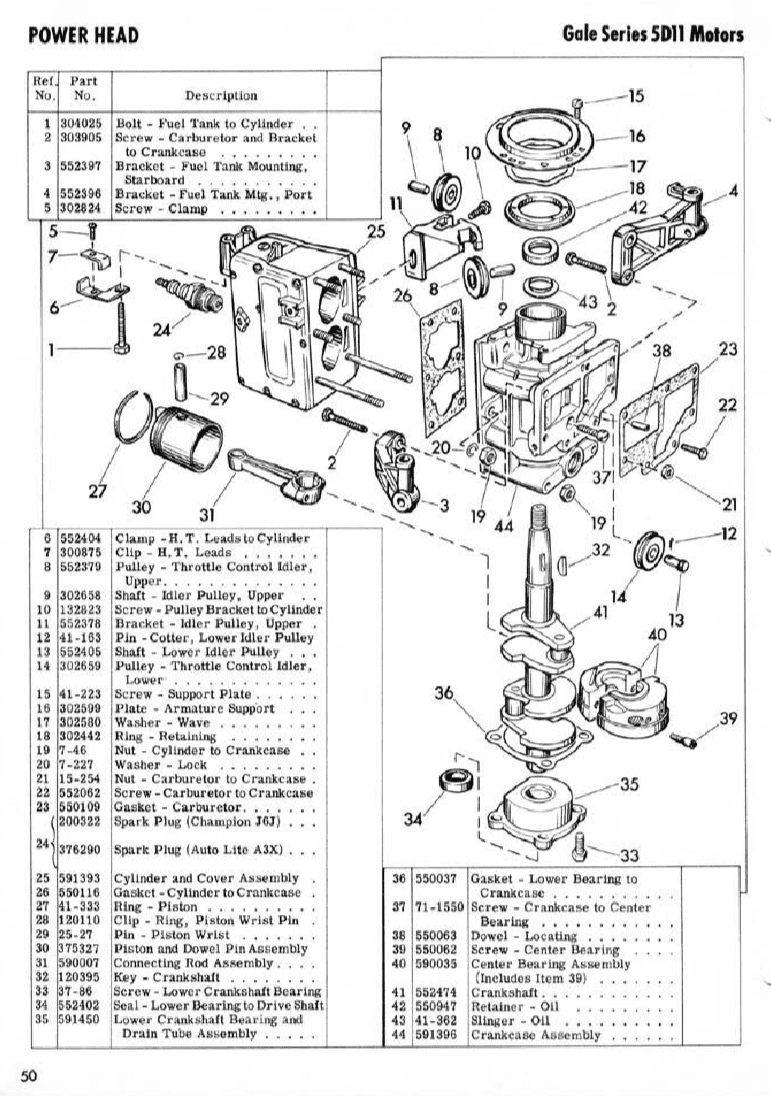

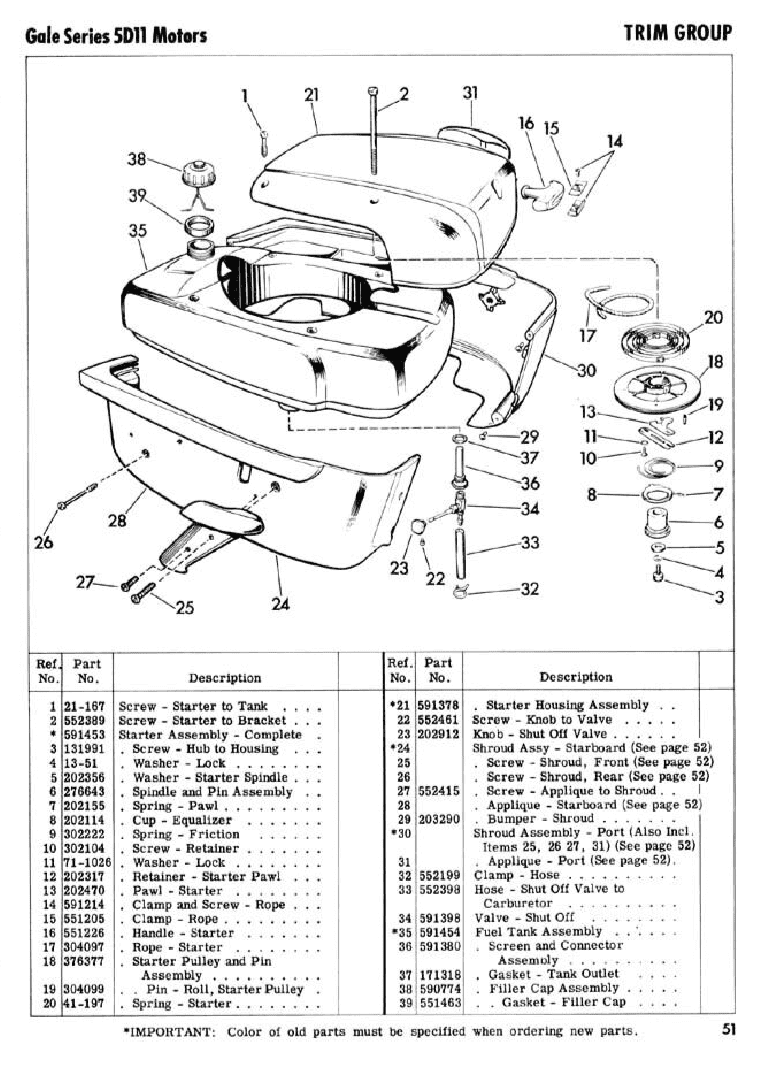

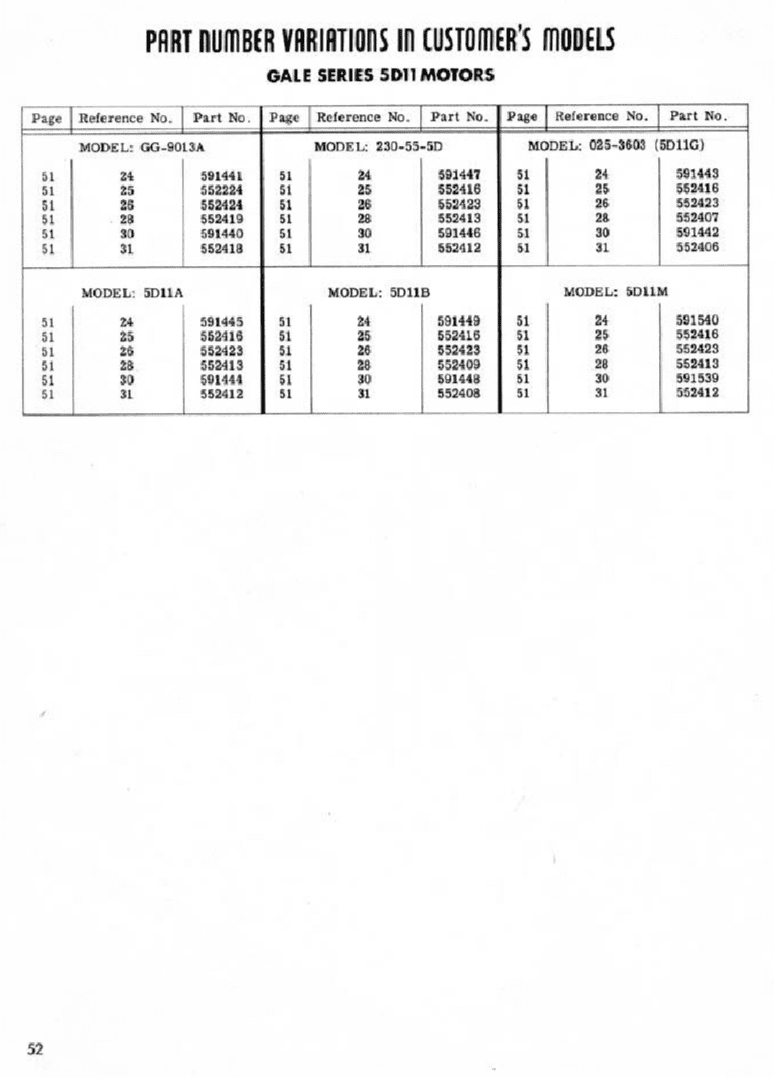

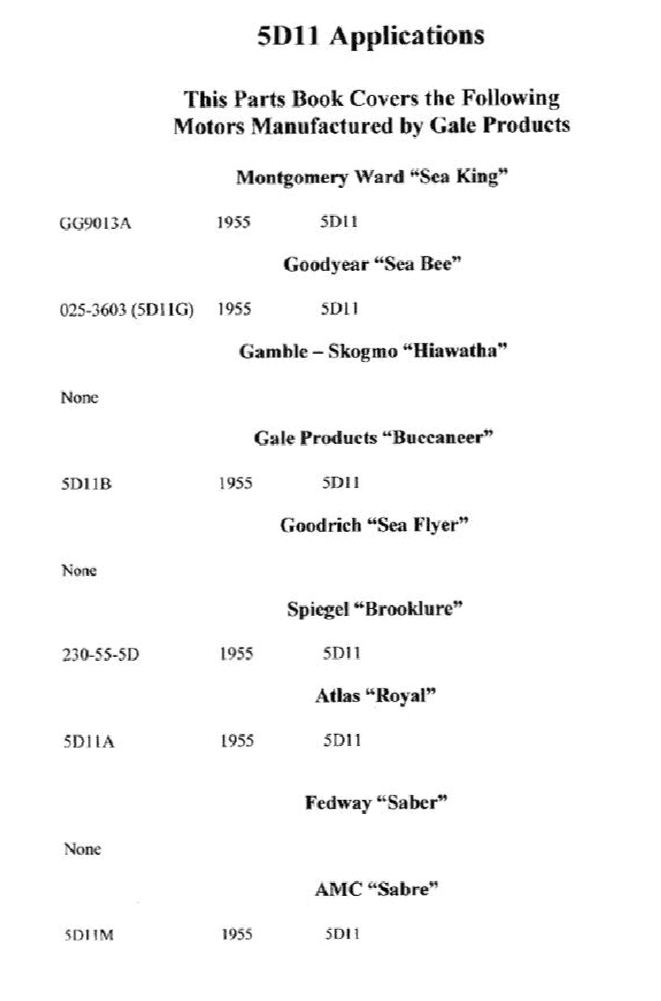

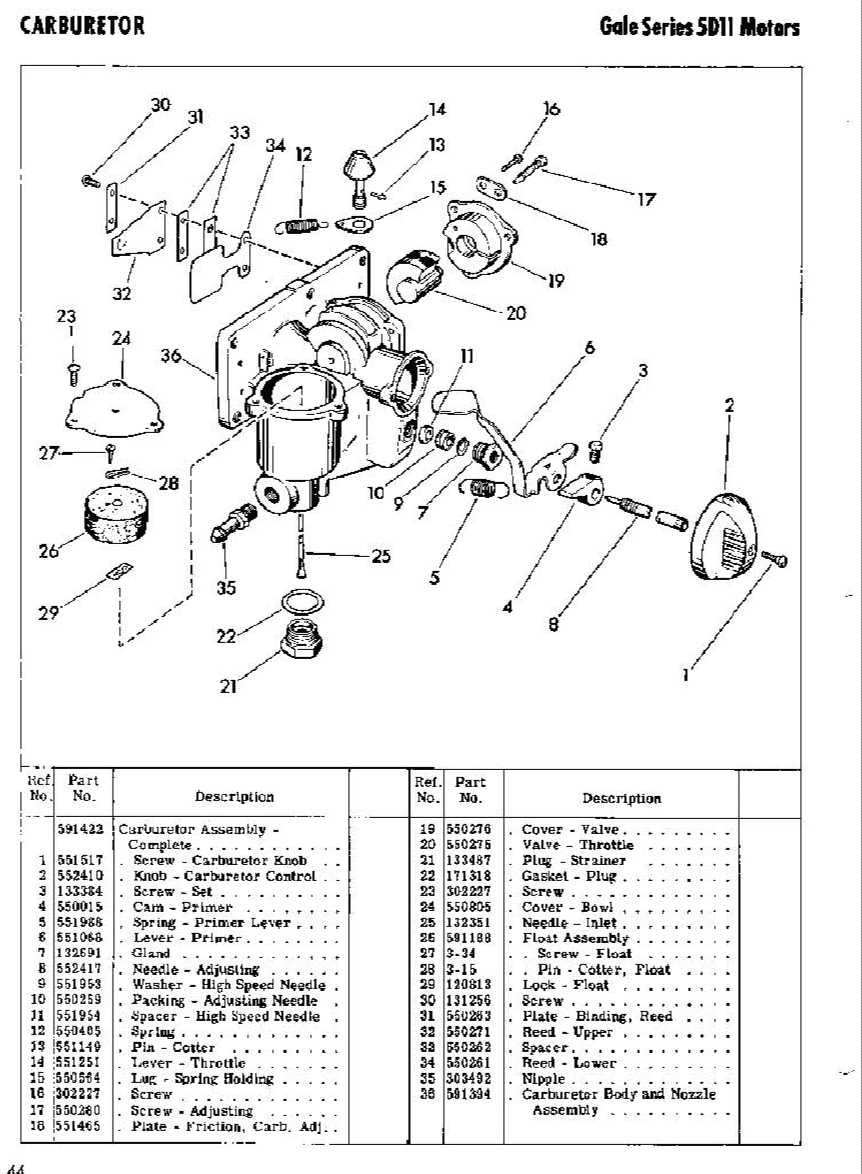

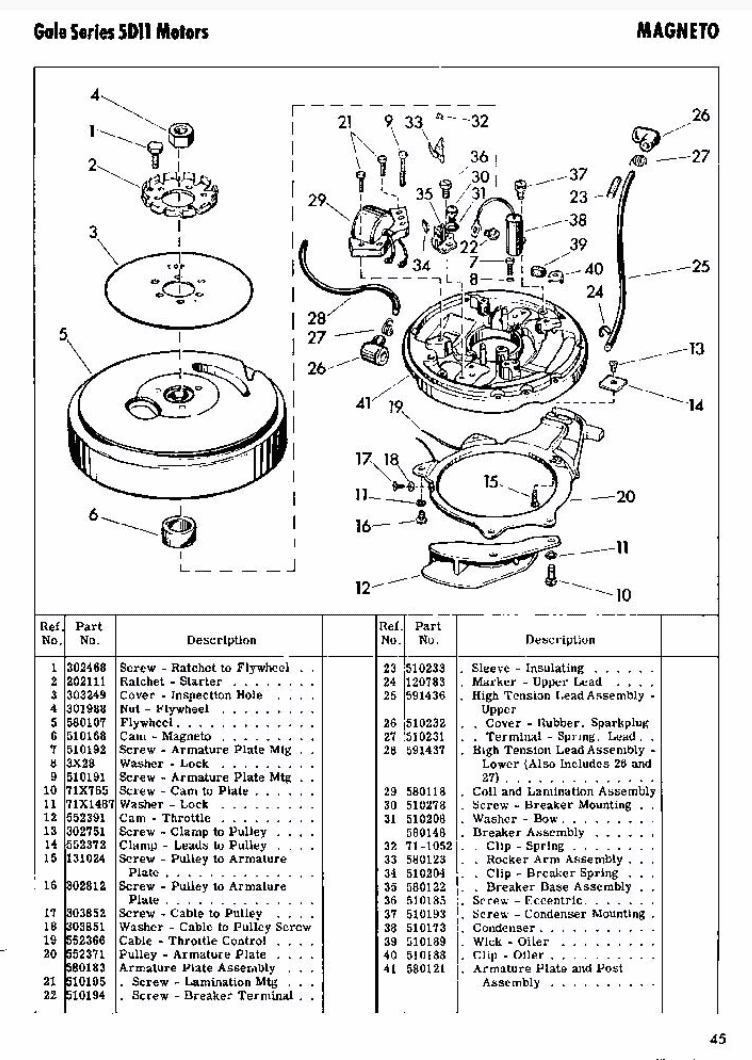

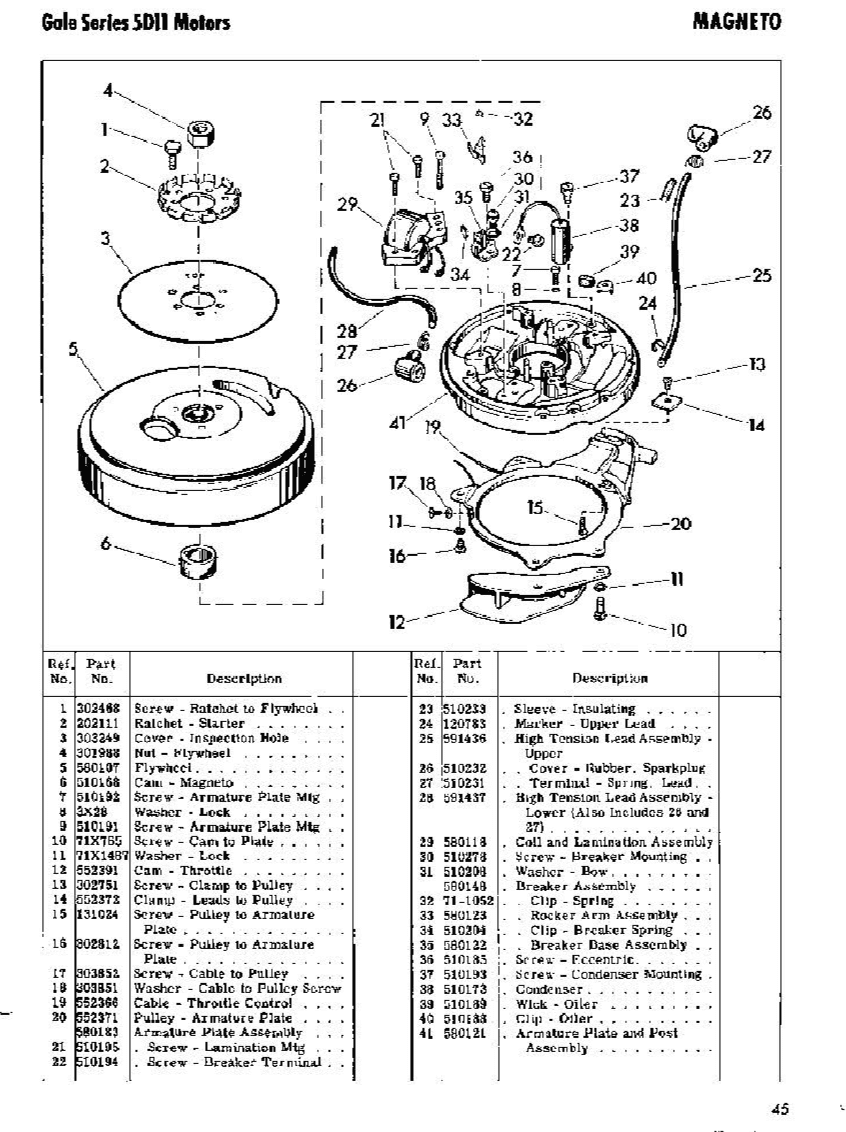

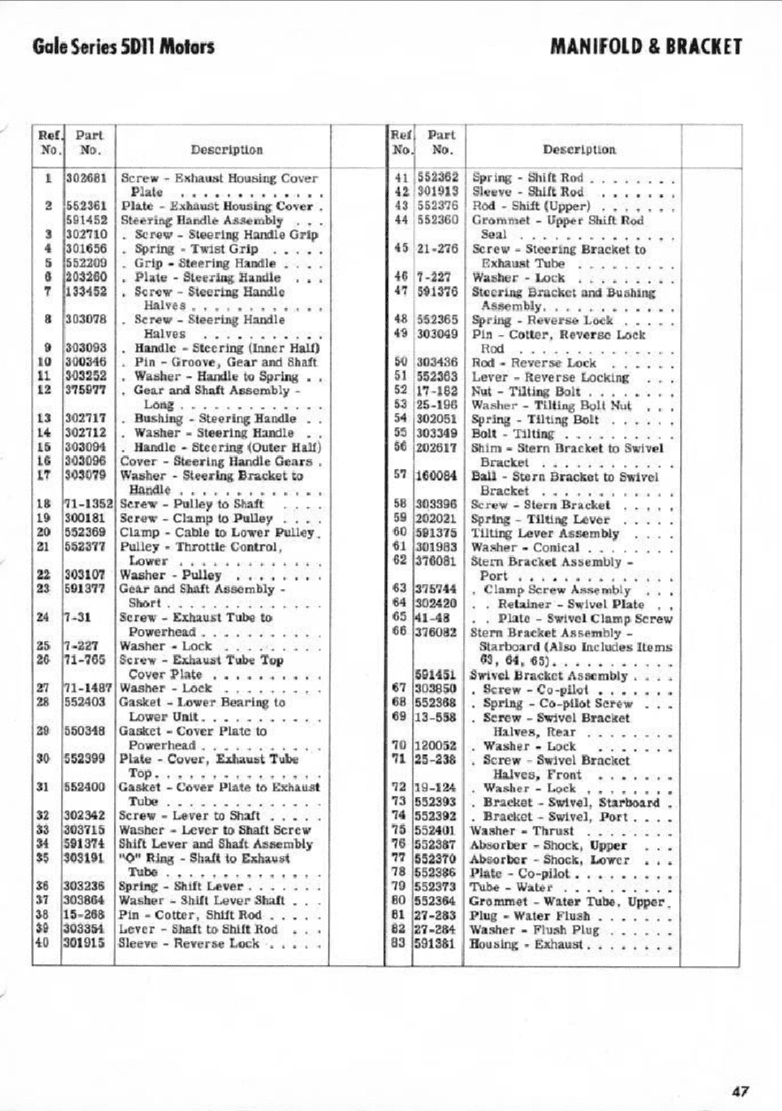

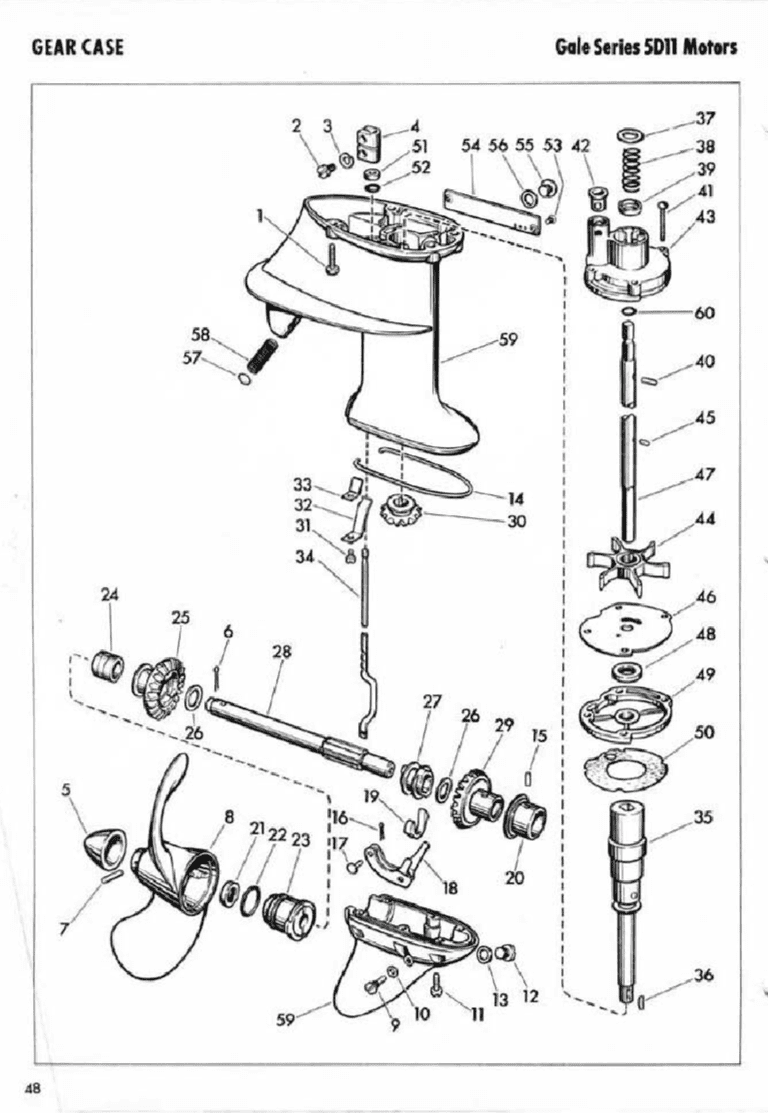

December 20, 2018 at 5:48 pm #160803Your model 025-3603 was built by the Gale Products devision of OMC, makers of Evinrude and Johnson outboards. The year was 1955 and it was Gale model 5D11G. This is from the Gale parts book . . .

-

This reply was modified 5 years, 5 months ago by

garry-in-michigan.

garry-in-michigan.

-

This reply was modified 5 years, 5 months ago by

garry-in-michigan.

garry-in-michigan.

-

This reply was modified 5 years, 5 months ago by

garry-in-michigan.

garry-in-michigan.

-

This reply was modified 5 years, 5 months ago by

garry-in-michigan.

garry-in-michigan.

December 20, 2018 at 6:13 pm #160815December 20, 2018 at 7:54 pm #160824hum…. no seal plate between spring #37 and 38 washer …don’t know for certain but maybe you should add a seal plate

it is a washer like plate with a centered rim facing upwards to center the cork washer

up to you…

Joining AOMCI has priviledges 🙂

December 20, 2018 at 8:47 pm #160833Yes, from the diagrams it doesn’t look like this model has anything but the washer above the spring. That’s what I’m seeing moving around up there. Thank you for the input and the parts diagrams!! Very helpful! This motor is not cosmetically the best but has never been worked on. Everything as it was in 55. Has great compression. Thought it would be a great winter project! Thanks again for the help!!

December 20, 2018 at 11:28 pm #160846seal plate 303356 from TIM’s outboard was only $5 …..cork 303355 was 3$ if you decide to add one in

a bearing seal 303391 may also be needed to push against the seal plate while refraining the spring from touching the seal plate underside

this is just a suggestion on my part some may disagree to “modifying” the design intent

p.s. the diagram is for a 7.5 likely similar to your engine and 5.5 ‘s of the time

all up to you now…

Joining AOMCI has priviledges 🙂

December 21, 2018 at 10:03 am #160860The 5D11 was a one-year model and didn’t have the usual carbon seal assy. Just a “washer” as said n the parts book. Sorry, I don’t remember the composition or nature of the washer.

Due to the different exhaust housing design, water ingestion through the bearing probably was not a problem. I’d guess the “washer” is more to prevent exhaust from blowing out around the drive shaft (???)

December 21, 2018 at 11:28 am #160863The washer looks to be brass from what I can see with a light. while we are in the subject of lower units , do they make a tool to remove and replace the water tube grommet on these older motors? Most of them I can reach with a long pair of needle nose but this one is 15″ up from the bottom right next to the block. Long ways up there!!

December 21, 2018 at 12:30 pm #160870if it works don’t fix it !!!

Joining AOMCI has priviledges 🙂

-

This reply was modified 5 years, 5 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.