Home › Forum › Ask A Member › bottom cylinder fouling Big Twin 25hp

- This topic has 31 replies, 9 voices, and was last updated 4 years, 3 months ago by

jeff-register.

-

AuthorPosts

-

October 25, 2020 at 1:31 pm #219302

Ok – I’m getting stumped on an issue I’m having with my ’55 Evinrude 25hp powerhead.

The motor has been hard starting recently but once it starts, it’s good to go for the rest of the day. idles perfectly; runs strong all day.i recently swapped out the spark plugs (to NGK’s for better starting) and somehow stripped the lower plug hole so I installed a NOS cylinder head and new gasket. While doing this i inspected the cylinders and made sure the rings weren’t stuck. it looked really clean and nice inside the cylinders.

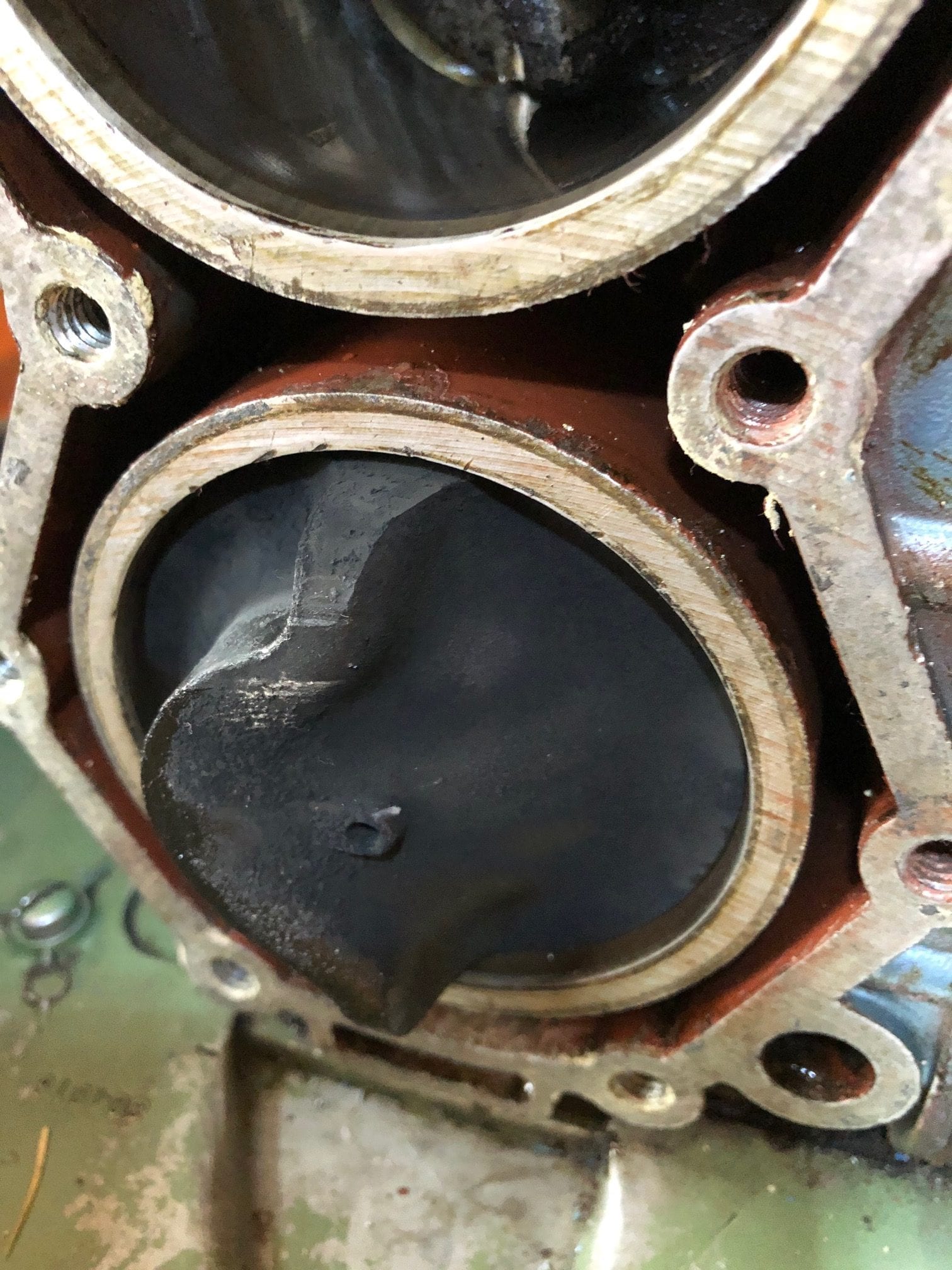

I went to start the motor yesterday for the first time since the new head was installed and i’m severely fouling the bottom plug. I pulled the head this morning and you can see the carbon on the piston (that wasn’t there before).

Yesterday when i finally got it running, i pulled the plug wires one at a time to make sure it was running on both cylinders and it was. fuel delivery seemed fine.to me it seems like the bottom cylinder isn’t getting spark (or enough spark) and building up carbon from unspent fuel very quickly. I thought maybe i had a broken ring which is why i pulled the head this morning but they checked out ok when inspecting them thru the bypass cover.

i have coils that are 2 years old and Atom electronic ignition modules that have never given me any grief. new plug wires too.

compression is 90 to 95 on each cylinder.any thoughts?

-

This topic was modified 4 years, 8 months ago by

Mumbles.

Mumbles.

October 25, 2020 at 8:48 pm #219341Kind of hard to say…. Did you decarbonize the pistons while changing the head? What does the other piston look like? What do the plugs look like? You seem to indicate that the engine runs just fine, except that it is hard to start cold. What is it that got you to pull the new head back off?

October 26, 2020 at 4:29 am #219347Just a guess but wondering if the head gasket was weeping water into the cylinder causing incomplete combustion.

October 26, 2020 at 8:29 am #219351The pistons didn’t need decarb when I swapped out the head. They were pretty clean with the normal amount of darkening. The top piston still looks like that.

The bottom plug was clean initially but after running like crap for about 5 minutes I pulled them. The bottom was completely black and somewhat dry and the top one was tan and just slightly damp (oil).

I pulled the new head back off because I thought maybe I screwed up the gasket or something since it wasn’t fouling plugs before. Gasket looked fine but tore when I removed the head – waiting for another one now.October 26, 2020 at 9:01 am #219352What about the “oil drain system” and that little flopper check valve in the front crankcase cover.

If that’s not working will you get excess fuel and oil in the bottom cylinder, causing

your symptoms?Prepare to be boarded!

October 26, 2020 at 9:08 am #219353What about the “oil drain system” and that little flopper check valve in the front crankcase cover.

If that’s not working will you get excess fuel and oil in the bottom cylinder, causing

your symptoms?Good point…I guess my question is how did the engine run/plugs look before the head change?? If all was well prior to the change, then something changed with the new head….How do the combustion domes look in the new head, and irregularities?? And, like someone else mentioned, perhaps there is a water leak somewhere, but usually this causes the opposite issue, pistons domes cleaned up from water bath…..

October 26, 2020 at 3:03 pm #219366Quite possibly you have weak spark at the bottom cylinder. Since the plugs are new, the problem might be with the spring connector inside the boot. Rust, corrosion, and old age can all cause a poor electrical connection here. Weak spark could also be caused by dirty points or a failed condenser, or an old coil starting to go South. With the Atoms installed, points or condensers won’t be an issue here.

October 26, 2020 at 7:13 pm #219385just wondering if you converted this engine to a fuel pump. i had a similar problem that was caused by a fuel pump diaphragm that was slightly torn.just a thought

mn

October 26, 2020 at 9:07 pm #219391Jim, I’m thinking the same thing with electronic type trigger. When I did research on the caps the rep said a mag is very hard on solid state parts. Tried looking up Ford transistor type switching with darlington type transistors failed too. Ford discintuned that ign so the transistors were hard to find too.

I too would look at leaf seating on the reeds too or a piece of dirt holding the leaf plate from a 100% seating position. Has the compression changed during repair process too?October 27, 2020 at 10:12 am #219418thanks for all the replies.

I’ll try to answer best i can.

– the compression is the same as it was before

– the cylinders and pistons looked pretty clean when i changed the head – normal darkening but no carbon build-up

– i too thought about the plug wires and connections since it was becoming very difficult to start even before the head swap. That is what i am going to check next although my plug wires and boots were replaced 2 years ago. perhaps the bottom one is loose.

– I do believe the bottom cylinder has a weaker spark because when i pulled plug wires when it was running there was a significant difference between the 2 cylinders and how smooth they ran individually.

– no fuel pump on this one; just the pressurized tank

– i haven’t checked the oil drain system – will check that also. what is the fix for that? new assembly or just clean?i have cleaned the new head and pistons; checked the rings to make sure they aren’t frozen; replaced a dirty inline plastic fuel filter;

now i am waiting for a new head gasket but in the meantime I will start with the plug wires and go from there.

the thing ran great all summer and only became hard starting in the last month or so – prior to the new head. so something has changed without me being the cause of the foul-up 🙂thanks again

-

This topic was modified 4 years, 8 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.