Home › Forum › Ask A Member › bottom cylinder fouling Big Twin 25hp

- This topic has 31 replies, 9 voices, and was last updated 3 years ago by

jeff-register.

-

AuthorPosts

-

October 27, 2020 at 11:53 am #219421

just curious … what have you measured in ohms value….. boot clip to engine frame ….both should be similar and steady if you wiggle the boots or wires

Joining AOMCI has priviledges 🙂

October 27, 2020 at 12:05 pm #219425Something to think about when using an ohmmeter to test plug leads, the meter can show continuity through the wire indicating it is good. But, if the internal core is broken and still joined by a single strand or there is a poor connection under the boot, the the meter will indicate the wire is good when in fact it won’t be able to carry the high voltage needed to fire the plug. Believe me, I’ve been stumped on this before.

October 27, 2020 at 12:41 pm #219428agree… the best option in this case is to recheck/redoo … replace all the suspect electrical components if any doubt exist on the quality of wires, boots, coil connections etc… at least it would eliminate that part of the puzzle (fuel oxygen…. fire)

the arrival problem coincides with the new cyl head presumably it was resurfaced and installed properly so the external variable here are the wires or plugs . (unless Murphy showed up in the meantime)

a bad plug interchange could move the problem over to the top cyl … end of problem 🙂

the next step is a close look over of the lower cyl HV circuit all the way back to the coil HV pin

jmho

Joining AOMCI has priviledges 🙂

November 10, 2020 at 11:27 am #220542I have been out of town and unable to work on this motor but I plan to do the following this weekend:

1. check crankcase drain

2. check coils with ohmeter

3. check continuity of plug wires. Likely will replace with new wires I have on-hand.

4. check all wiring under the flywheel; solder and re-connect

5. install new spark plugs

6. I have spare Atom modules – I might swap out the one for the lower cylinder with a new one just to be safe

7. verify ignition-throttle synchro

8. remove sintered element in carb fuel bow (I have installed an inline plastic replaceable fuel filter and can’t tell if the bowl filter is clear or not).

9. examine high and low speed needles.any other thoughts on this list or the order?

November 10, 2020 at 12:13 pm #220544#3 above is probably your best option.

November 13, 2020 at 3:58 pm #220779update:

just starting to try and diagnose this motor this weekend.

first step was testing the coils and plug wires.

tested the primary windings on both coils and got a reading of .9 with my digital multimeter set at 200.

I got a reading of 4.55 and 4.50 on each when i tested my secondaries with multimeter set at 20k.

I tested the secondaries by putting one lead in the spark plug boot and the other one to the ground wire on the coil.with this result I think I’m confident i have good coils and the plug wires are good.

I have Atom ignition modules on this motor but do not have any way to test them that I know of.

do you guys think the coils and wires are good from the readings above?

am I missing anything?-

This reply was modified 3 years, 5 months ago by

The red boat. Reason: spelling

November 13, 2020 at 6:50 pm #220792imho.. coils measure fine …yet it is possible to test OK resistance wise…..while a low coil insulation spot allows the high voltage to jump to engine ground.

One way to prove this out would be to swap the coils to see the the issue migrates or suddenly disappears . you may want to do a close visual on the coil feeding the lower cyl to see if you have dark burn spots (assuming the coils are not black to start with 🙂 )

have you ever checked if the coil sparks will jump 5/16 to 3/8 across such a gap … at the very least using an old plug with the ground tip broken off the sparks should jump to the plug body with a SNAP !

Joining AOMCI has priviledges 🙂

November 14, 2020 at 8:41 am #220822thanks for the reply.

my coils are indeed black but I’ll inspect them and see if i see any burn spots.I think I am going to disassemble everything in the magneto and reassemble and swap coil locations. then I’ll check the spark!

November 15, 2020 at 9:02 am #220877Ok so here’s what I found on this Evinrude as I try to diagnose the lower cylinder issue:

when I went to test the coils and plugs wires and rebuild the mag, there was quite a bit of oil on the plate.

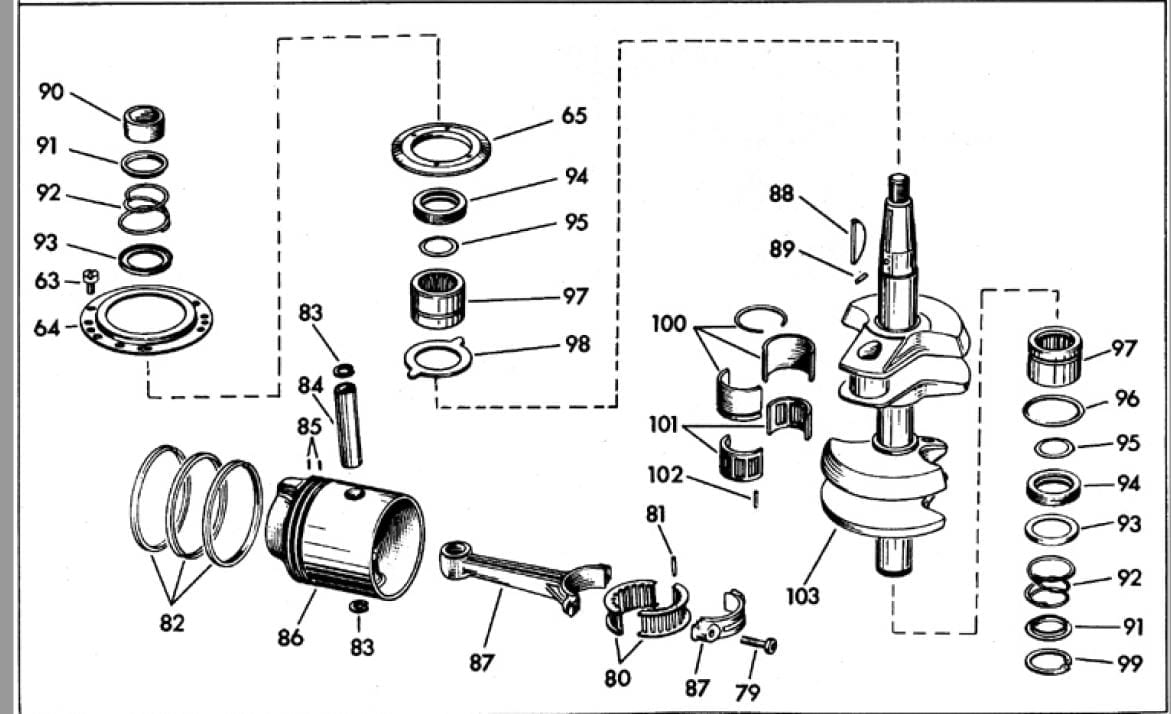

I removed it and the mounting ring below to discover that parts 91 and 92 in the attached diagram were missing. I did have the carbon seal which i promptly chipped and the other items in the upper seal.

I replaced the carbon seal and a new quad-ring and installed the missing parts (dang it – I was saving those and that carbon seal for my Johnson rebuild I’m starting this winter).

I then swapped the coils and installed a new Atom module for the lower cylinder and soldered all wiring connections. Then tested with multi-meter.

I also installed new copper core plug wires just to have all new stuff.could the oil from the upper seal have caused the Atom unit to malfunction and provide week spark?

I wonder where the missing pieces went…I’ve never gone past the magneto plate on this motor.as part of my diagnosis I also inspected the crankcase drain and found nothing. chased a thin wire through the drain opening and blew it out with compressed air after removing the little copper reeds.

Next thing to do is install new plugs and check for spark.

one other thing I noted: there was a lot of oily residue inside the hose leading to the cut-out switch. More than I’ve noticed previously. The hose was original and showing signs of cracking so I replaced that too. When I test this motor I will disconnect the cut-out switch completely so i can test the rest of the components on their own.

could this be one of my problems since the cut-out switch affects the lower cylinder only??-

This reply was modified 3 years, 5 months ago by

Mumbles.

Mumbles.

November 15, 2020 at 6:33 pm #220907Were there any actual running issues with this engine? A problem with the ignition vacuum switch cut out system would kill the cylinder it is connected to…

-

This reply was modified 3 years, 5 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.