Home › Forum › Ask A Member › Elto Super A connecting rods

- This topic has 17 replies, 7 voices, and was last updated 5 years, 2 months ago by

Bob Wight.

Bob Wight.

-

AuthorPosts

-

October 19, 2020 at 12:37 pm #218869

As I was checking the rods to the crankshaft for “fit” this morning,

I noticed the one has a “twist” in it.It’s hard to guess if it’s enough of a twist for the intake and exhaust

profiles of the piston top to be an issue with matching cylinder portings,

but I “think” not.I see no physical damage to the rod, so not sure why it’s twisted.

Could have been that way from day one for all I know.The rod appears to be some sort of bronze material.

I’m tempted to try to twist it back in shape, but not sure if I want

to chance damage or snapping it in half in trying to straighten it.Any thoughts based on experience in the matter?

-Leave well enough alone?

-Straighten it (how best done?)?It wont be going to a machine shop, so that suggestion is invalid, lol.

Thanks.P.S.- The last photo is to remind myself to save the next Guerny’s Seed catalog.

My .009 gasket stock is running low!Prepare to be boarded!

October 19, 2020 at 3:39 pm #218882

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

October 19, 2020 at 5:12 pm #218888It seems like it would bind some with the rod end and piston pin not being parallel. Can’t imagine how it got twisted though.

October 19, 2020 at 6:29 pm #218891I’ve already honed the cylinders, but will check the piston again, but

I don’t remember seeing any glaring problem with uneven wear on

the “twisted rod” piston. But you got me thinking that I need to

measure or eye up the piston pin to see if it’s parallel with the crank….

I think the rod is only noticeably twisted, but hopefully not bent sideways

as well.Prepare to be boarded!

October 20, 2020 at 11:44 am #218957

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

-

This reply was modified 5 years, 2 months ago by

Tubs.

Tubs.

October 20, 2020 at 1:10 pm #218963Tubs, somewhere I have seen fixtures for checking connecting rods for trueness.

Not sure if the same fixture was used for straightening them as well.

I’m sure it was common practice for mechanics “back in the day” to rework

all the rods.Prepare to be boarded!

October 20, 2020 at 8:34 pm #218981Buc I just read an article in Motorcycle classics magazine September/October issue. I fella was rebuilding a Honda that dropped a valve and messed up the motor big time. The connecting rod was twisted. He placed the rod at TDC clamped the crank so it would stay there. Put the wrist pin in the crank with a long punch for leverage. Heated the rod nice and red gave it the eagle eye treatment. When he was happy with the position he poured some oil on the rod to cool it off. Suppose to retain the hardness doing the oil thing. That bike runs great, how long it stays that way is another story to come!

dale

October 20, 2020 at 8:38 pm #218982Dale, I haven’t tried anything with it yet. Not sure I’d head it “red” being a bronze rod.

Gotta wonder if quality control wasn’t all that good back in 1932, or if my rod

had a mishap along the way.Prepare to be boarded!

October 20, 2020 at 9:45 pm #218986

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

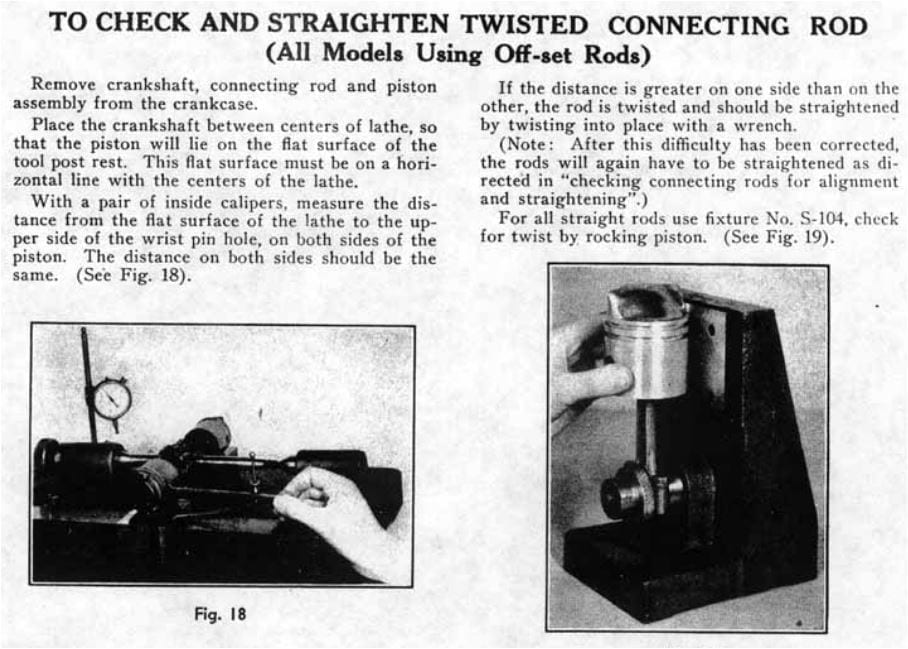

October 20, 2020 at 9:53 pm #218987Here’s the Johnson method for straightening twisted rods. It should work for Eltos to.

-

This reply was modified 5 years, 2 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.