Home › Forum › Ask A Member › Evinrude 25hp Big Twin Model 25018 “The Evil One”

- This topic has 41 replies, 10 voices, and was last updated 3 years, 7 months ago by

Shamus.

-

AuthorPosts

-

September 5, 2021 at 9:24 am #246152

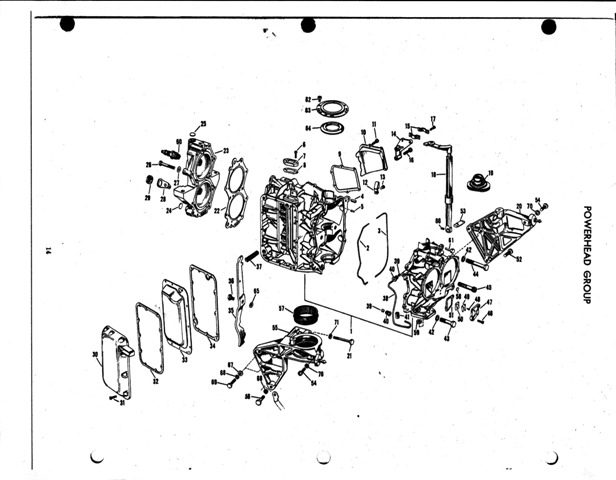

My experience with Big Twins is limited to five motors including three 1956 Johnson 30HP. But I suggest that you just concentrate on getting the motor to run. First address the lower crank seal. You can change shaft length later if you care and address any safety concerns you have once it runs. In my limited experience to correct the lower seal issue you will wind up opening the crankcase anyway. If you do open the crankcase, you should replace the top crank seal too. (easy).

As discussed, to change the seal from lip seal to carbon type you would change the lower bearing, and add the parts associated with the carbon seal.

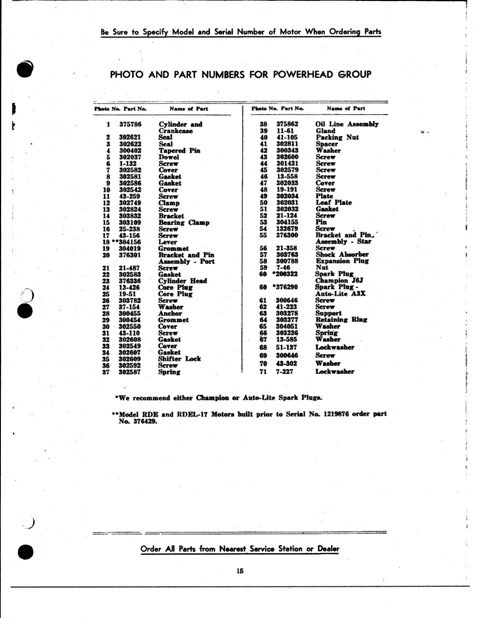

The carbon seal parts are shown in the parts list for the 1956 Big Twins.The 1955/56 BigTwins are sweet running motors worth the trouble and cost to bring back into service.

1 user thanked author for this post.

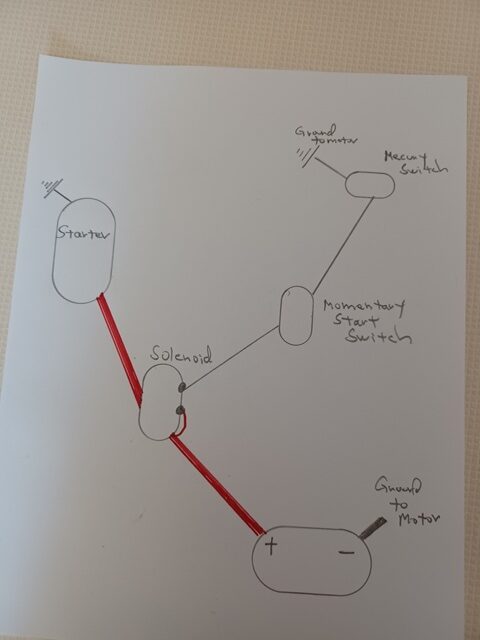

September 5, 2021 at 10:48 am #246163Any micro switch common to industry would work, most are double pole single throw 1 set contacts normally closed one set normally open. Position switch on shift linkage where it can be activated in neutral or use two switches one activated forward one activated in reverse. Either setup will be wired in series between starter solenoid and key or push button switch. If running 2 switch setup wire switches in parallel so either switch will interrupt starter signal to solenoid. Single switch activated in neutral should allow signal to pass to starter whilst activated and be open whilst switch is not activated. It isn’t a correct to build set up but, it is a safety system being retrofitted, therefore I see no harm in modifications being made. Placement may be tricky not too familiar with big twin set up, but on the 22CI motors I’d set it up to activate off the magneto plate detent arm as it is only fully in by the magneto plate in neutral; reverse and froward it moves away from the power head and magneto plate.

-

This reply was modified 3 years, 10 months ago by

Nicholas Keller. Reason: Typing too fast for logic

Nicholas Keller. Reason: Typing too fast for logic

1 user thanked author for this post.

September 5, 2021 at 7:23 pm #246204I sure would like to know how to exactly do this micro switch work around on a big twin

September 5, 2021 at 9:42 pm #246219Studying the photos in this post the lay out is the same mechanically as the Fastwin (19.5-22 CI motors) making a bracket will be required. If solenoid is not mounted under the cowl you may need to add wires. Unsure of how exactly the factory mercury switch works, I would presume it to interrupt the starter solenoid trigger from the ignition switch or starter button if this is the case wiring it in place of mercury switch would work. None of my engines had a mercury switch so I came up with this after a good scare which made stressful situation worse. Positioning can be challenging depending on size of switch. The ones with longer metal arms usually help I don’t like the ones with rollers on the end as they are typically too bulky. Honeywell V3L-1122-D8 is a good switch to work with. Though confirm specifications can handle amperage load of starter solenoid. I used this switch as I had a couple laying around. Currently I don’t have an engine readily available to photograph with modifications I have mentioned. Re sealing power head on my 1970 Johnson 25 hp, which had this modification installed.

1 user thanked author for this post.

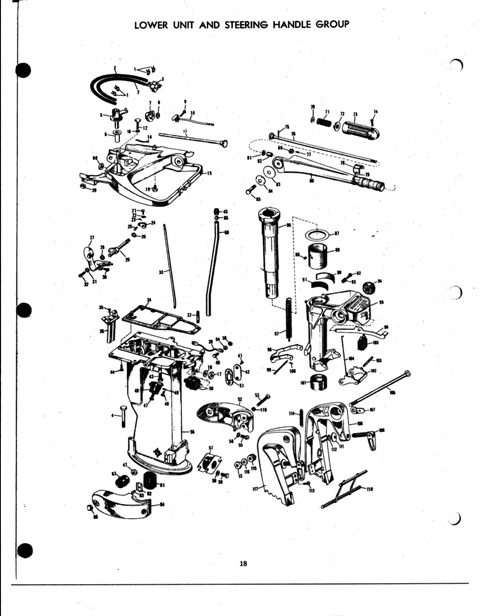

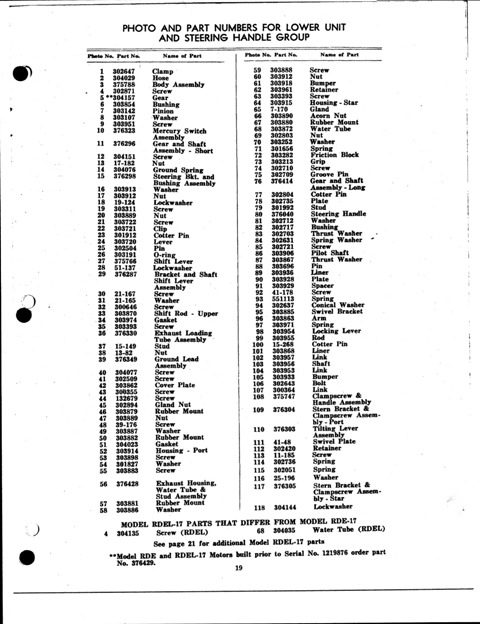

September 6, 2021 at 1:31 pm #246238September 6, 2021 at 1:32 pm #246243September 6, 2021 at 8:32 pm #246275Part 35 “shifter lock” on second photo posting. That will be closest to the power head in neutral

September 6, 2021 at 8:47 pm #246277This winter I will be working on a RD-17 (in pieces now)

I will check out how feasible it actually would be.

ThanksSeptember 7, 2021 at 1:31 pm #246313Sounds good.

December 2, 2021 at 2:40 pm #250576OutboardNut, thanks for your info to date. Its been a great help. Are you back to a place where I could give you a call? I’d like to chat about what parts I will need to acquire to change that carbon seal. I pulled off the magneto found what appears to be oil all over the bottom of the magneto. Is this a sign that both the upper and lower crankshaft seals are gone bad? Is there a test to show where the oil has come from?

-

This reply was modified 3 years, 10 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.