Home › Forum › Ask A Member › Johnson RDE-17R?

- This topic has 53 replies, 11 voices, and was last updated 7 years ago by

lindy46.

lindy46.

-

AuthorPosts

-

January 4, 2017 at 7:10 pm #50309

No magnetised parts in these starters. The field coils and armature windings magnetize when they are energised. Just make sure you get all of the Bendix drive parts back in their correct order. Something else to watch for is the lower thrust washer. On these vertically mounted starters, they tend to wear causing the commutator to short out against the lower end plate. Making a new non-conductive thrust washer out of Delrin or something similar seems to solve this problem.

January 5, 2017 at 1:47 am #50346Fast forward about twenty years, and they did start making the fields out of permanent magnets. That permits a more powerful starter with less current draw. Lots of modern cars have starters as small or smaller than your outboard. But don’t drop or beat on one of them. The magnets may shatter.

January 5, 2017 at 3:12 pm #50362That is interesting, you learn something everyday! Thank you guys again for putting up with all of my newbie questions but boy am I learning a lot.

January 24, 2017 at 3:39 pm #51614Sorry to keep bringing up my thread but I have lots of questions as I go through this motor.

I serviced the starter and tested it by running jumper cables off my truck battery to it. It turned over nicely and was smooth and quiet. I made sure not to turn it for long since I was running a 6V starter on 12V. The Bendix portion also worked as it should raising and lowering as I supplied power to the starter. I assumed that it was good to go so I put it back on the motor and proceeded to break one of the mounting bolts off in the process. I was able to get it out of there and replace it without much headache though.

I finished up the rest of the pieces that I hadn’t cleaned yet and re assembled the rest of the motor. The mag plate gave me some headache due to the cut out wire that runs to the vacuum switch not being routed correctly, but once that was sorted out it went in fine. I also re routed the green wires coming off the coils so that they wouldn’t rub on the flywheel and shortened the black wires. Then I gapped the points to 0.020". I then replaced the plug wires to the correct copper core style and routed them along the motor. I installed new plugs that I gapped to 0.030" and then cut the plug wires to length and installed new ends and boots.

I then put the flywheel on and it was hitting something so I pulled it and found that it was hitting one of the laminations on the coils. I reset that and then put the flywheel back on and then tested for spark. I had great spark on top and pretty good on bottom but it wasn’t as hot as the the top was. Then I cleaned and serviced the pull start and re installed that. I also replaced all the fuel lines, vacuum lines and set the carb and roller cam in accordance with the service manual at this point.

I couldn’t wait any longer time to see if it would start :). I put gas to it and attempted to start it by jumping it off a battery out of my boat. The starter would turn enough to the the bendix to pop up and engage and maybe turn through one compression stroke but that was it. I tried multiple times with the same result so I gave up on the electric start and pull started it instead. After a dozen or so pulls it fired up and idled fairly well for just setting the carb where the service manual said to (1 1/4 turns out on the low speed and 1/3 turn out on the high speed).

https://youtu.be/6h0LWBJSxPAI am very happy to hear this thing fire up (not for long since it didn’t have the lower unit on) for the first time in 40+ years but now I am concerned about the starter. Does anyone have any suggestions on what to do to get the starter to work properly? Thank you all for your help thus far in this project you guys have saved me a lot of headaches!

January 24, 2017 at 4:57 pm #51621First of all, what was done to the starter when it was serviced? Was the armature checked for shorts, was the commutator turned and polished with new brushes installed? Were the gaps between the commutator segments cleaned out really good and the insulation between them cut down? Are the field coils and their insulation in good shape with no shorts? What about the bottom thrust washer, is it worn and causing the commutator to short out against the lower end plate? Have you tried bypassing the solenoid and using jumper cables straight to the starters terminal? Are all of the connections clean and tight?

That starter should spin the motor over quite easily so it sounds like you have to go back inside it and do some detective work.

January 24, 2017 at 6:00 pm #51627Mumbles

The starter was rusted tight when I got it so it was broke free and then disassembled. The commutator was turned and polished. The points looked to be in decent shape so they were sanded down a bit and then polished. The bottom thrust waster looked to be in good shape so nothing was done with it. All of the gaps on the commutator were cleaned out but no insulation was cut out of it. All of the field coils looked to be in good shape as do their insulation. I did not check for shorts anywhere though and I am not really sure how to go about doing this. When I was trying to start using the starter I was using jumper cables not through a solenoid. Any further knowledge about what to look for when I get back in there would be helpful. Thanks

January 24, 2017 at 6:31 pm #51629

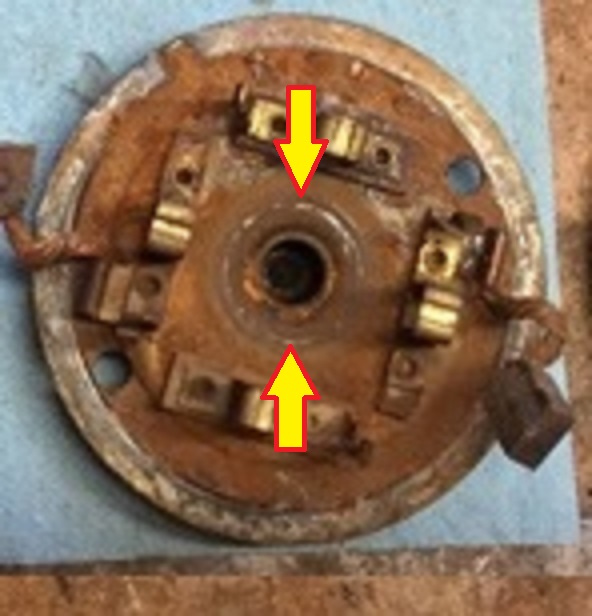

January 24, 2017 at 6:31 pm #51629It sounds like you did a thorough job on the starter but something caught my eye. The lower end plate in the photo shows a shiny ring on it. This could be from the thrust washer (#26) or from the commutator rubbing on it. I don’t see the separate thrust washer in your parts layout so it might be missing. I know it’s a PITA but you might want to go back in and measure the shiny ring against the end of the commutator or pull the armature out slightly with the end plate and brushes attached and visually make sure the commutator isn’t rubbing on the end plate. The thrust washer supports the weight of the armature and starter drive and does wear out, especially if water has made its way in.

January 24, 2017 at 8:53 pm #51636Thank you mumbles for the great info. The thrust washer is in there it is just installed on the end of the commutator in the picture. It looked to be slightly worn but not bad. Is there supposed to be any play up and down when the whole thing is put back together? Mine has a little bit of play to it I’m not sure how much but a bit. I can measure that when I get back into it. I am assuming that the shiny ring that you are pointing out was caused by me breaking the commutator loose. It had been rusted tight so I got a breaker bar on the nut to break it loose enough to get the whole thing apart. I am guessing that this is where that bond broke but I could be wrong. I will be sure to post updates as I get back into it but at least now I have a good place to start to look for a problem. I now see why it was never used as an electric start by the previous owner. At least it is turning so there is hope.

February 13, 2017 at 5:24 pm #52947Sorry to pop this back up to the top of the page again but I wanted to provide an update on my motor.

The original starter is an Autolite MAK-4033M and for the life of me I couldn’t get it to work so I finally gave in and bought an Autolite MDH-4001M off of ebay that was supposedly working and it came off of a RDE-18. I was told all of the 6 volt starters would just bolt up so I figured that this was the way to go instead of rebuilding the one I had (it was cheaper). As soon as I received the new starter I noticed that something was wrong, it is WAY smaller in size compared to the 4033 which meant that it couldn’t just bolt up even though they are both 6 volt starters. Luckily however the 4001 came with the bracket (part #376507) which just happens to have the same bolt hole locations as the original so it would bolt up. The bendix needed rebuilt on it so I did that and put it on there and wouldn’t you know it cranked it right over, so finally past that problem I just now have red bracket on a green motor.

I also was able to get the rear cowl bumper post fixed. I got this motor without a cowl and was able to purchase one for it from another member on here (thanks Scott) but one of the rear bumper posts was completely gone. I drilled and tapped the spot for the new post and then threaded in a new 5/16" bolt with some lock tight on it. Once it was in I cut the head of the bolt off to the same height as the original post and filled it down to smooth it out. Now it works just as good as the original.

Now all I have left is to finish the lower unit and water pump and put that back on and it is good to go for some sea trials to make sure there isn’t anything majorly wrong with it before I tear it down for paint. I also need to make a wiring harness now that I know everything electrically is working.

As always thank you to everyone who has helped me through this project I have learned a ton.

February 13, 2017 at 6:42 pm #52950Nothing wrong with or unusual about having a red bracket on a green motor, or a blue bracket on a red motor, etc. I have a blue powerhead on a white motor ;). It may not be 100% original, but neither is a beautifully restored motor. If this one was cosmetically restored no one would even know except you. The most important part is to have fun.

-BenOldJohnnyRude on YouTube

-

AuthorPosts

- You must be logged in to reply to this topic.