Home › Forum › Ask A Member › KG7 Water pump replacement

- This topic has 8 replies, 8 voices, and was last updated 3 years, 2 months ago by

fifty20ne.

fifty20ne.

-

AuthorPosts

-

January 19, 2021 at 6:04 pm #228175January 19, 2021 at 6:57 pm #228190

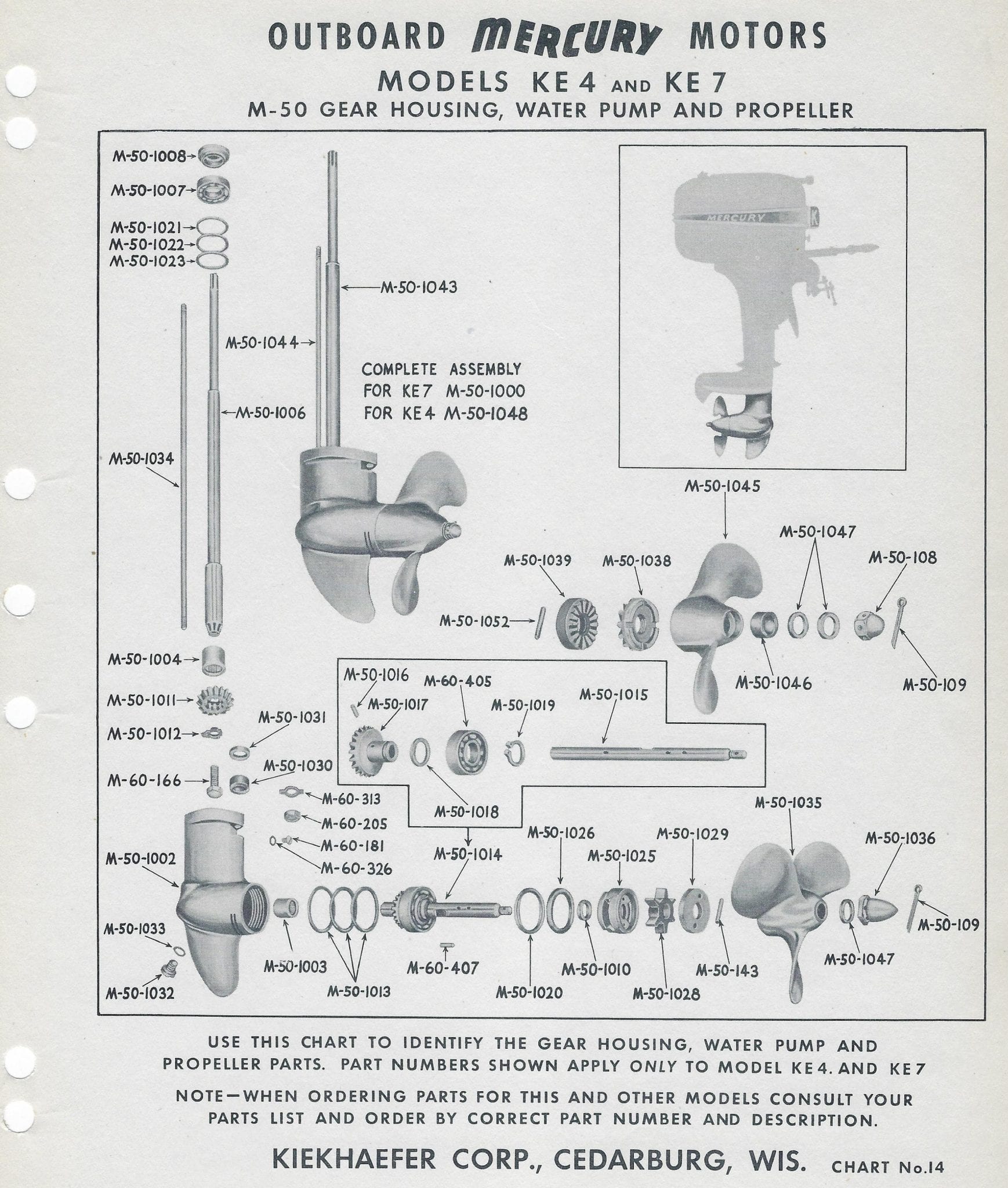

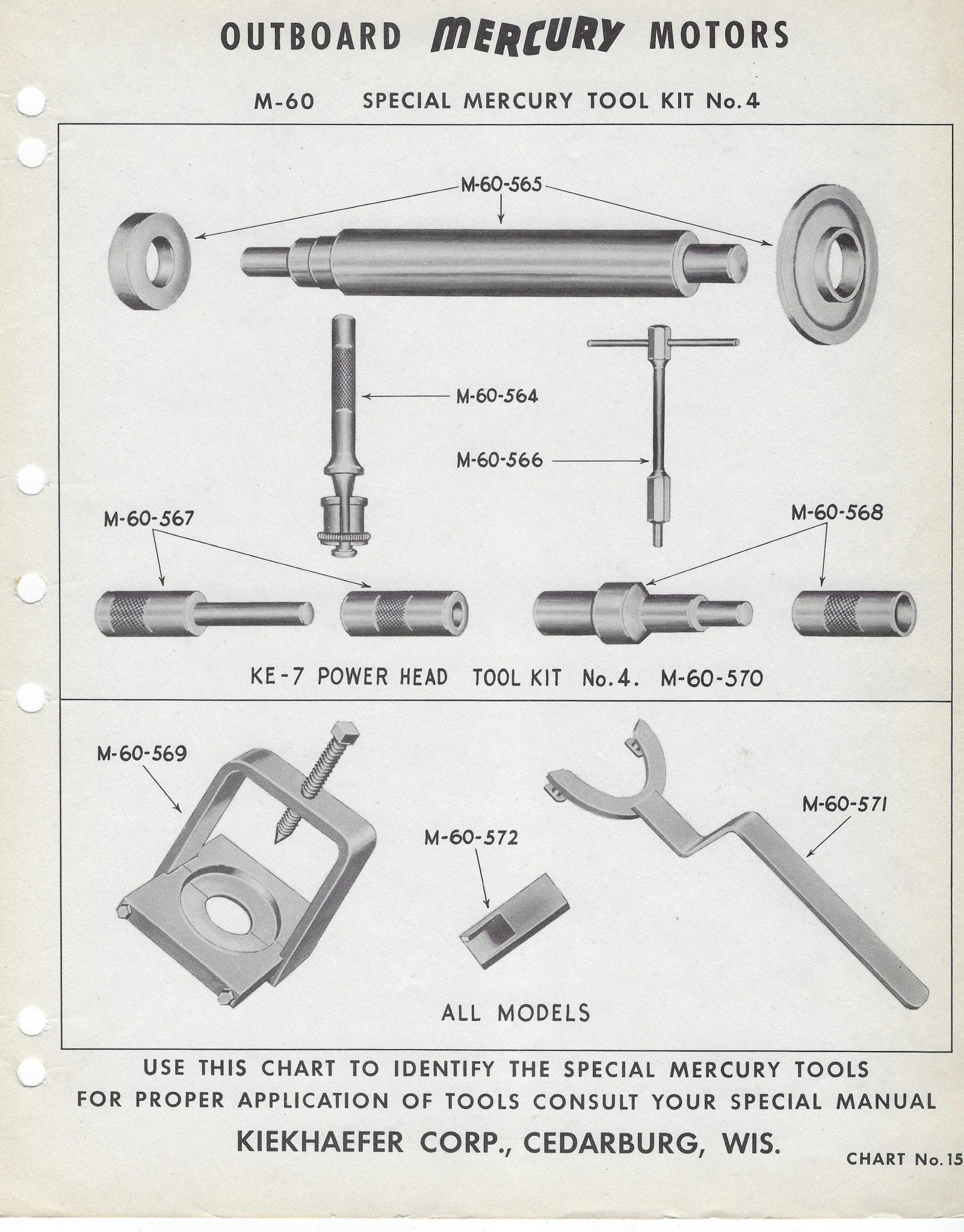

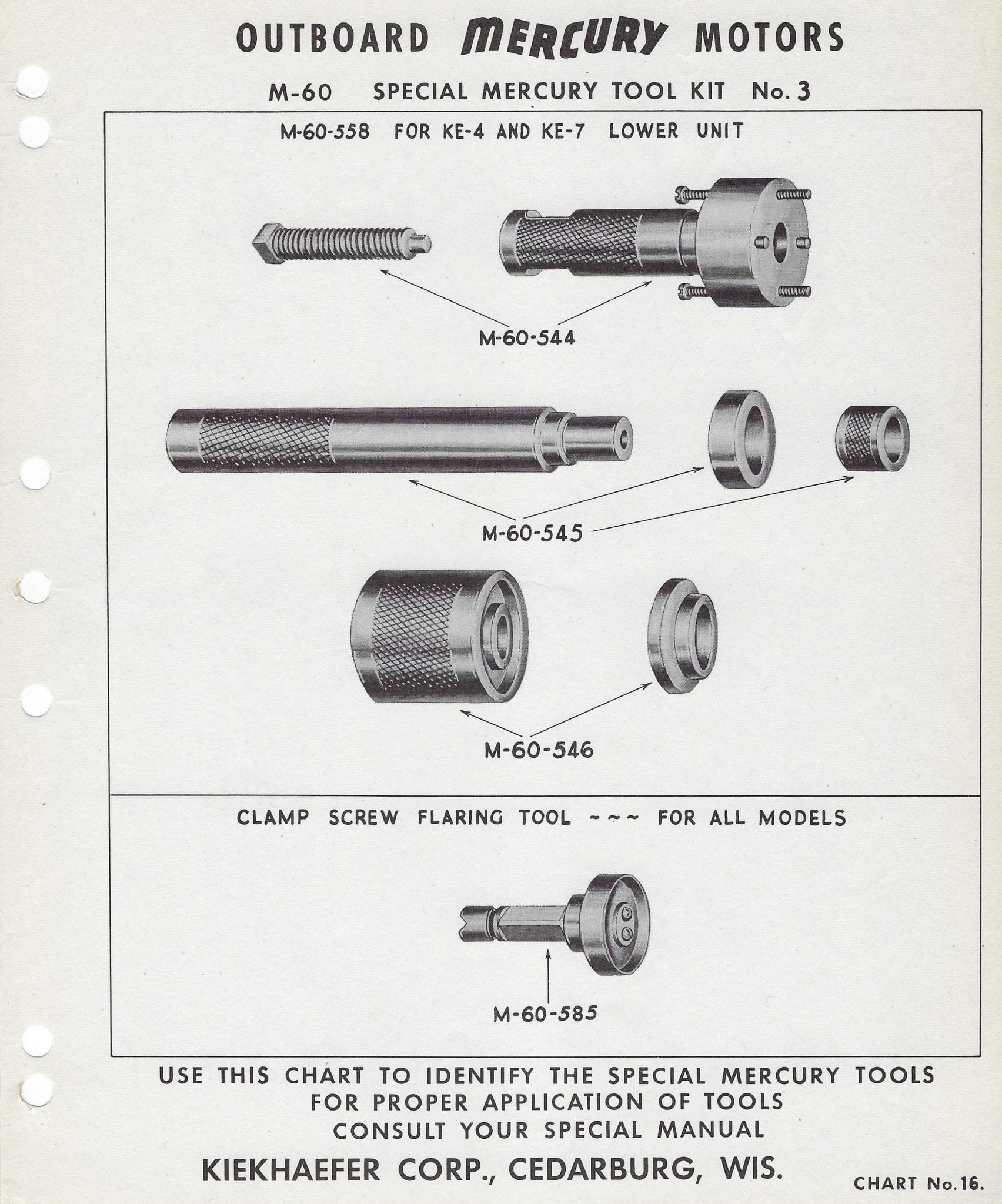

I don’t recall that thrust washer being difficult to remove. I think it just slides off. But the plate under it with the two holes can be very difficult for several reasons. First of all you will need the special Mercury tool that engages the two holes so that you can unscrew the plate out of the hole to access the impeller. Second of all the plate has backwards threads on it, and that is critical!!!! Normal threads are “Righty Tighty” and “Lefty Loosey” but the threads on the plate and inside the gearcase are backwards to keep the plate on during prop shaft rotation. So if you try to unscrew the plate in the usual left hand direction it will just get tighter and make it even harder to unscrew the correct way. I made a special tool just like the special Mercury tool and it worked perfectly. You can borrow my tool if you are here in my shop but I will not sell it. It will be included with my restored and serviced KG7 that has custom made steering bracket for remote steering, Quincy Exhaust manifold, A variety of stock and speed props, etc.

January 19, 2021 at 6:58 pm #228191sock and tap first then try 2 large screwdrivers behind it . cover is left hand threads. call me for tips first.

1 914 310 7086,January 20, 2021 at 5:34 am #228231Tools can be made in various fashions, to engage those two holes used for removal. Agreed that you will be turning it clockwise to remove, when looking at it from behind the motor. One trick is, after making a tool, use some bushings, washers, etc and and a spare nut that fits on the prop shaft threads, to gently tighten and hold the tool engaged into the holes in the cover. If you don’t do this, the tool will want to walk up out of the holes and round out the holes. Once the cover starts to budge and turn, back off the nut on the prop shaft accordingly, as the pump cover backs out.

Long live American manufacturing!

-

This reply was modified 3 years, 2 months ago by

billw.

January 20, 2021 at 9:53 am #228243 January 20, 2021 at 7:10 pm #228322

January 20, 2021 at 7:10 pm #228322Personally, I have no use for a Mercury. But, with that said, one needs to understand why those w/p covers are so hard to remove. It has to do with the threads of the disc. Aluminum will easily gall. When those discs were made, the threads were rough, which didn’t affect it going in, but, as you try to back it out, the burrs in the threads will try to reverse position, and when they do, they act like anchors. Imagine a water pump impeller. As it turns, the blade curve backwards and take that position. If you try to rotate the impeller the opposite direction, the blades will act as a brake. The same holds true for the burrs on that disc.

Before you install a new disc, rotate the disc in some 320 grit, or close, wet/dry sandpaper to remove the burrs. Then clean the threads well before you install. It should screw in easily,–if not, clean them again.

George

January 21, 2021 at 9:09 am #228357I have removed many of these covers on Mercs. I have never had a problem with threads, and only had one that would not come off without drilling holes and breaking it out. I am sure that a good part of the reason is that I do not have to deal with motors from salt or brackish water. I made my own pin spanners to fit different covers. Coating the threads with anti-seize before reinstalling will assure easier removal next time.

January 21, 2021 at 10:24 am #228364That worked, I got the thrust collar removed. I am soaking the plate now with PB Blaster.

January 22, 2021 at 3:00 pm #228497 -

This reply was modified 3 years, 2 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.