Home › Forum › Ask A Member › my 1941 Sea King

- This topic has 5 replies, 4 voices, and was last updated 4 years, 5 months ago by

fifty20ne.

fifty20ne.

-

AuthorPosts

-

October 31, 2019 at 8:22 pm #186243

I still wish I could find out what that little ball does in the bottom of my motor.. The brass cap, I removed and there is a little ball in there . Is there anything else that goes in there or am I missing something.. I hope someone can help me .I almost think that has something to do with the water problem.

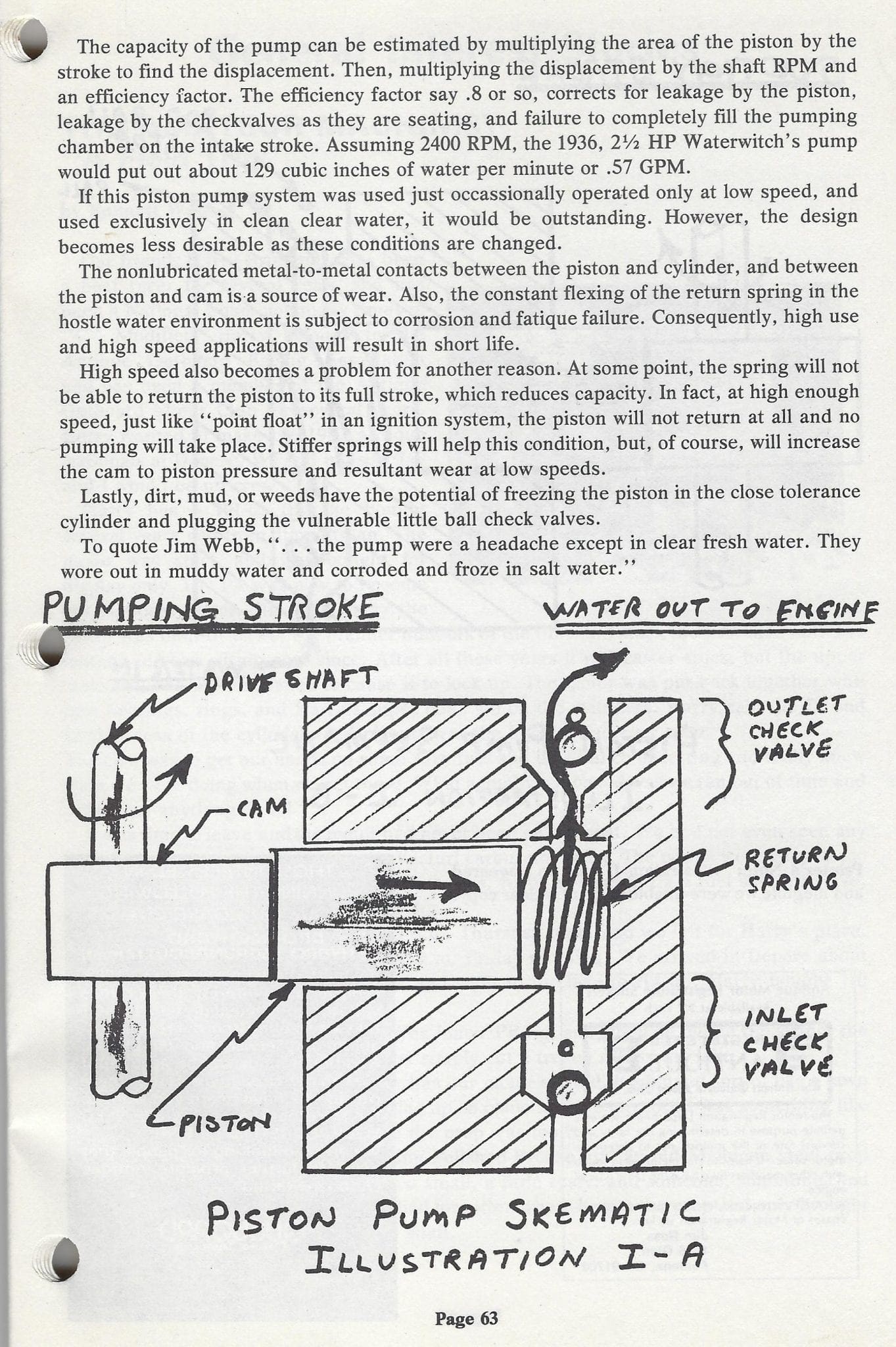

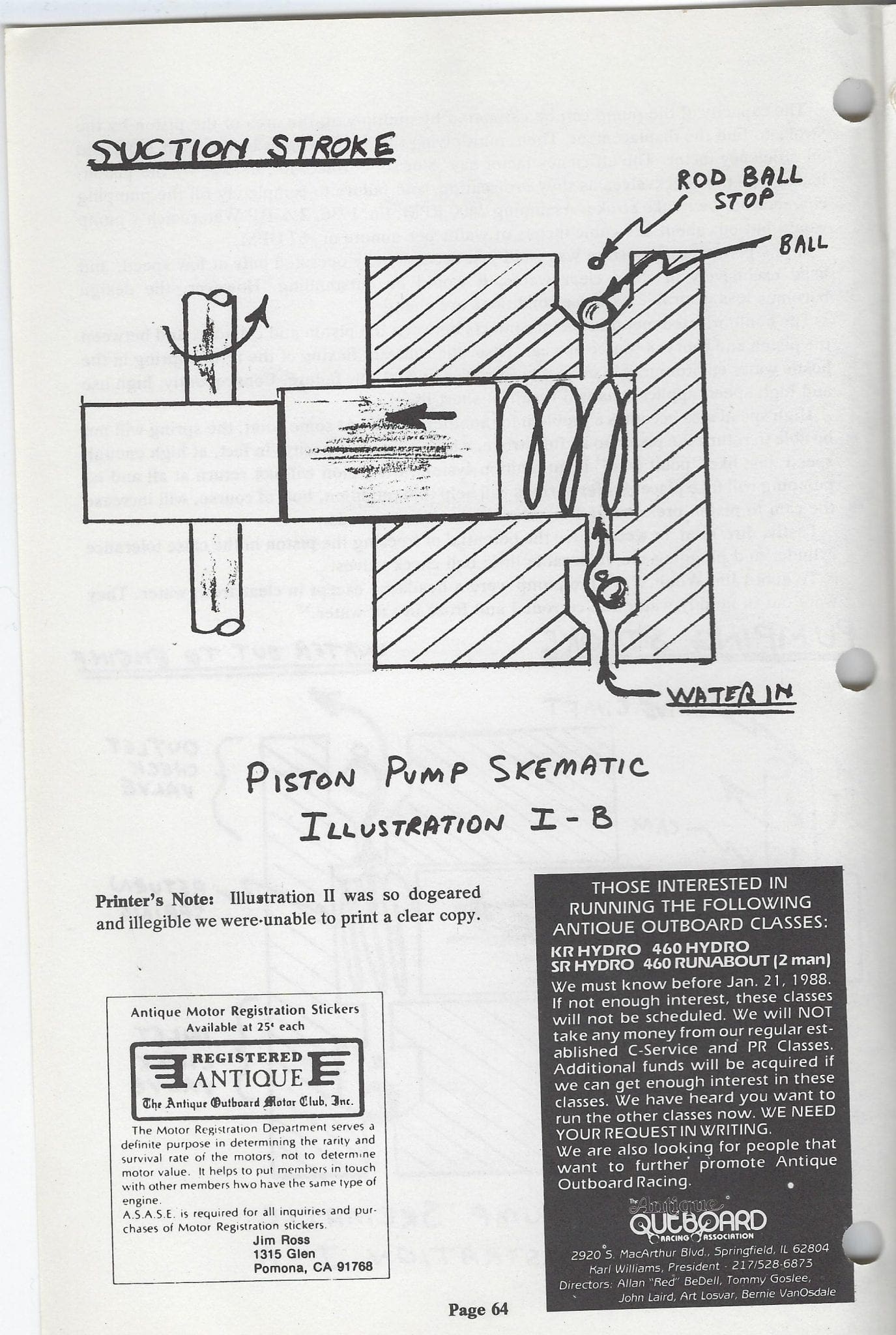

October 31, 2019 at 9:05 pm #186249That stainless steel ball is a valve. It allows water in when the spring in the piston makes the piston follow the eccentric but closes the hole when the piston reverses direction forcing water up the water tube. If the head of the piston has a hole in it from the eccentric or is stuck in place or if the spring is broken, it won’t pump water. There should be another ball close to the base of the water line. Both should move freely.

-

This reply was modified 4 years, 5 months ago by

garry-in-michigan.

garry-in-michigan.

November 1, 2019 at 1:55 am #186255The 1939 and earlier Sea Kings used a piston style water pump. The 1940 -41 Sea Kings used an oscillator style water pump.

The ball bearing in the brass part is the check valve. The ball bearing (check valve) must not be rusted and must be free to

Move in order to work properly! As Gary stated above (See Picture) #2 the red disk is the check valve in diagram.

Also the water intake is on the bottom and the intake holes must be open (not plugged up)Piston pumps are durable, fairly simple devices. The basic piston pump is made up of a piston, a chamber, and a pair of valves. The pump operates by driving down into the chamber, thereby compressing the media inside in a hand pump this is usually air. Once the pressure of the air exceeds that of the outlet valve spring, the compressed media is sent through the open outlet valve. When the piston is drawn back up, it opens the inlet valve and closes the outlet valve, thereby utilizing suction to draw in additional media for compression.

Piston pumps are a type of reciprocating pump, which are positive-displacement pumps that can use a piston, plunger or diaphragm to displace fluids. The input and output valves in a piston pump are check valves; this term is used to describe devices that limit flow in a system to one direction. Piston pumps can be driven manually or automatically, and there are a number of devices that can be used to drive the piston. A common piston pump design is the rotary piston pump, which uses a rotating shaft or wheel to drive the piston. The rotating component is attached to an intermediary shaft at a point away from its center, and this shaft is attached to the piston. As the rotating component turns, it drives the shaft and piston down and then pulls it back up.

A large portion of piston pumps are axial. Axial piston pumps use multiple cylinders grouped around a main axis. The pistons within each cylinder are attached to a swash plate, which is attached to a rotating shaft. The swash plate is also known as a cam or wobble plate. As the shaft turns, the angle of the swash plate changes, which drives the pistons in and out of their respective cylinders. Radial piston pumps are used less frequently, but are preferred for certain applications; both radial and axial pumps are available as fixed or variable displacement pumps.

Although fairly expensive, piston pumps are among the most efficient pump types. They have an exceptional pressure rating (as high as 10,000 psi), but their design makes them quite susceptible to contaminants. They provide an excellent solution for many high-pressure hydraulic oil pumping applications.

Click here to find Piston Pumps Manufacturers

References:

The Efficiency of Reciprocating Pumps

ShareMo

November 1, 2019 at 11:38 am #186275November 1, 2019 at 2:53 pm #186285Oops wrong motor, same principle! Thanks Tubs. Good Luck,

Bob

November 4, 2019 at 10:50 pm #186488 -

This reply was modified 4 years, 5 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.