Home › Forum › Ask A Member › OMC Pinion Shaft Shock Absorber

- This topic has 18 replies, 10 voices, and was last updated 6 years, 5 months ago by

fisherman6.

fisherman6.

-

AuthorPosts

-

January 8, 2019 at 4:56 pm #162243

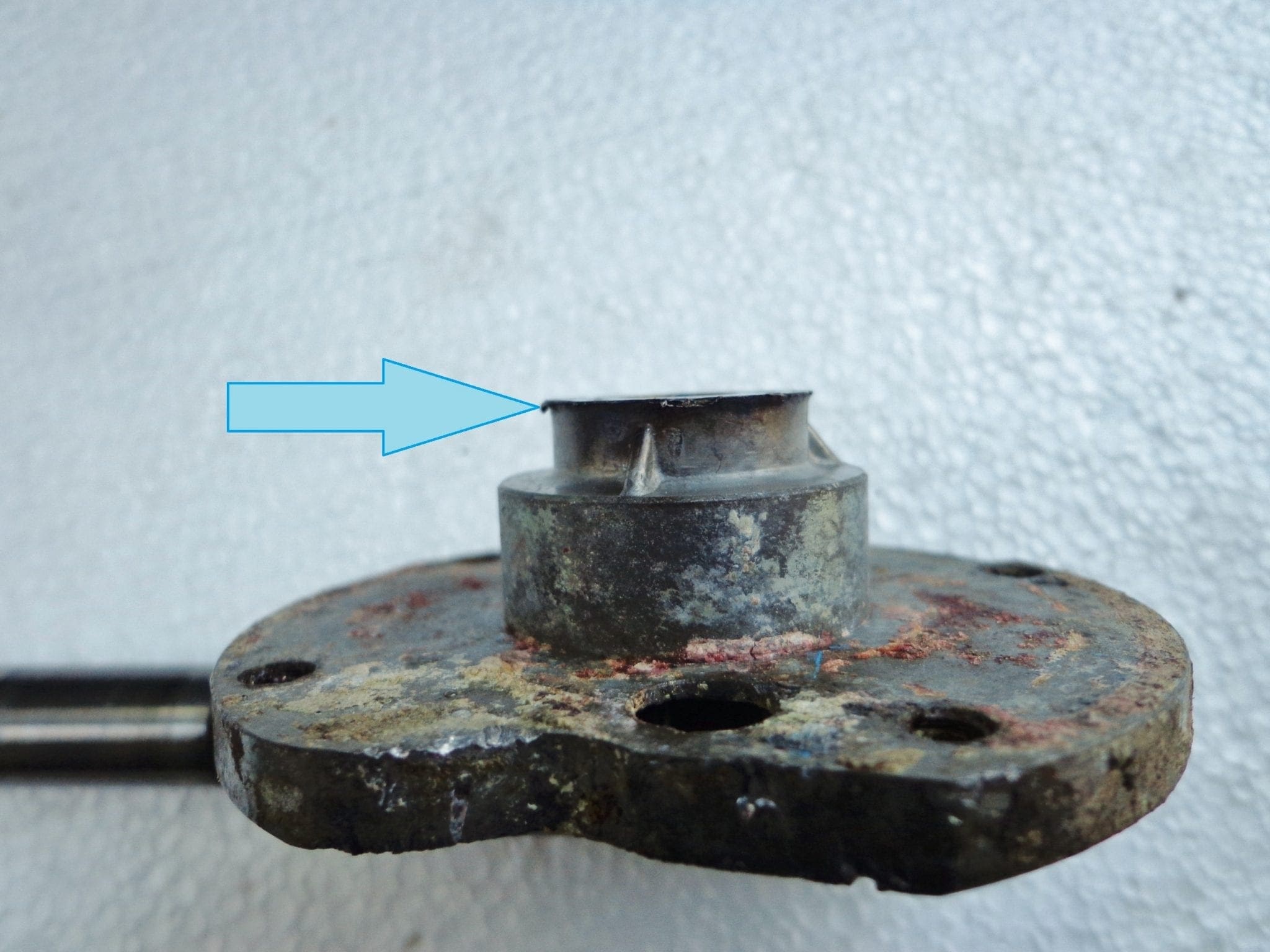

Today I came across a perfect example of a shock absorber used in the pin drive 5.5 and 7.5 horse motors which has done its job and is now oversize in length and rubbing on the bearing housing causing a stiff or tight motor syndrome.

When I measured it, it was 0.142″ oversize. That’s more than 1/8″ so something had to be done about it.

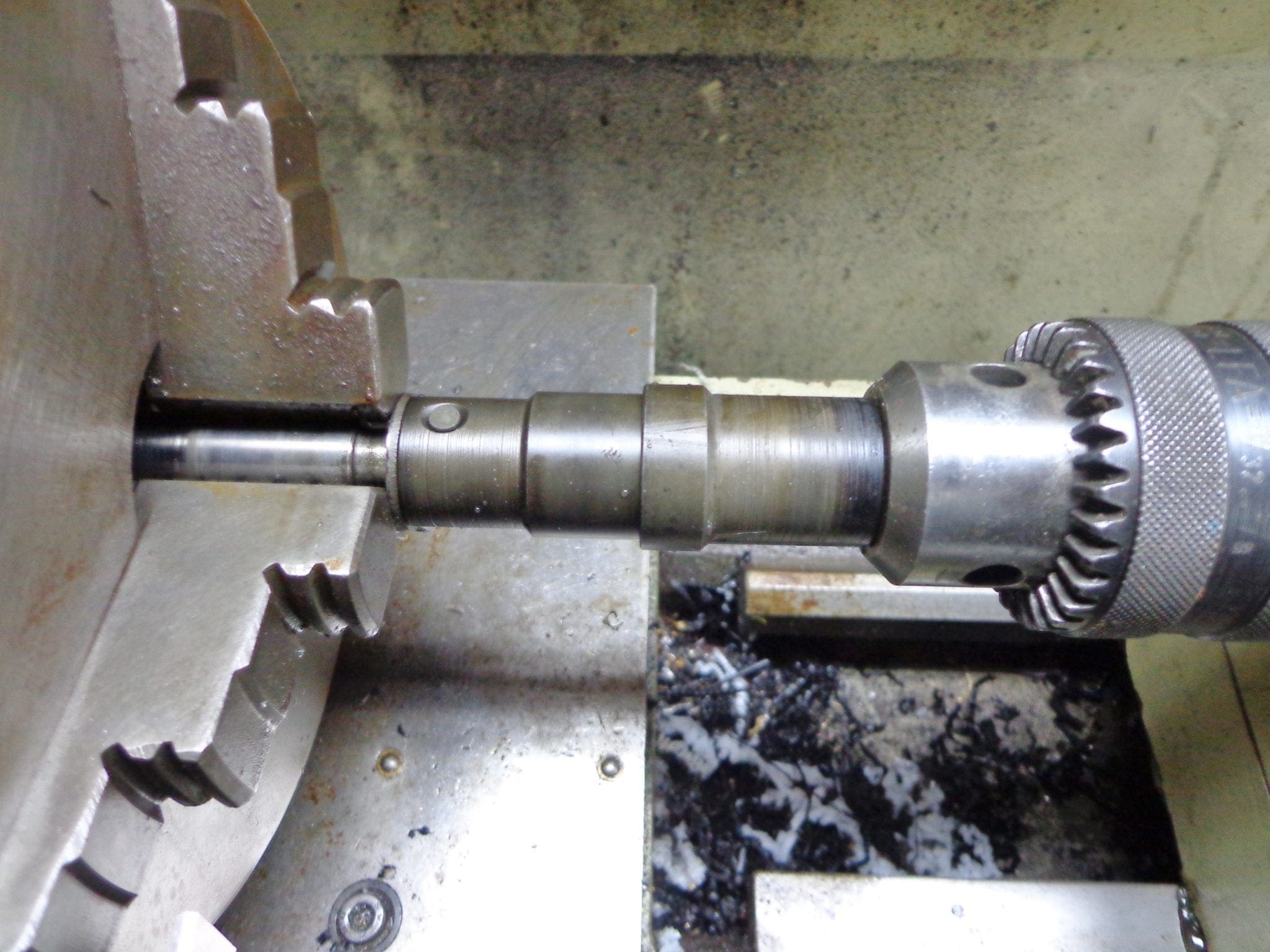

Usually these can be shrunk in size by pressing or pounding on them but when I mounted it in the lathe and tried to press it using the tail stock feed, it didn’t want to budge. The twelve ton press is hard to get at right now so I switched it end for end and coaxed it with a few blows from a two lb hammer.

6 11/16″ is the length I was aiming for and the two pounder did the job!

January 8, 2019 at 8:00 pm #162366I always put them back together with a 2-3lb hammer. It’s qiuck and very effective. The welder prevents this condition from happening again.

-BenOldJohnnyRude on YouTube

January 8, 2019 at 8:01 pm #162367Good info and good fix – thanks for sharing.

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1955 Johnson QD-16

1957 Evinrude Fastwin 18

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."January 11, 2019 at 7:32 am #162750Great Thread. I have an Evinrude 5.5 shock that I found the spring to be broken.It fits back together with no force needed and I have a question or two.

Is the total length of the shaft to be 6 11/16 ” (which mine is)

And if I were to weld it (my welding skills are limited) what would be the best method?

Thanks Kenwww.kenadianoutboards.com

-

This reply was modified 6 years, 5 months ago by

Ken Smith.

Ken Smith.

January 11, 2019 at 9:52 am #162754I’ll leave it to others to advise the procedure. But just for a FYI, the one I attempted turned out to be unusable due to resulting mis-alignment. I suppose it has to be held in alignment while welding.

January 11, 2019 at 11:22 am #162756Like Frank says, they have to be kept in alignment if you’re going to weld them. The bottom of the drive shaft fits into a slot or something inside and if they aren’t straight, they won’t work right.

I braze welded a few before realizing compressing them back to length would work but I used the handy dandy lathe to keep them straight. Spinning it dead slow while doing the job allowed it to heat up and cool down evenly while being held in position. A lathe isn’t really necessary but keeping it straight is.

January 11, 2019 at 11:57 am #162761When I weld mine I use a MIG welder. Once the shock absorber is pressed back to its correct dimension it has to be cleaned thoroughly. Residual oil will seep out once it is heated and adversely affect the weld. I do not find that I need to hold them during welding to keep them straight as long as it is straight before I start welding and I use some care and judgement during welding. I normally use 4 good tacks around the circumference of the joint where the upper and lower halves come together. As long as you get decent weld penetration into both halves the 4 tack beads will never break loose under any amount of abuse that an OMC 7.5hp engine will throw at it, especially if you go to a brass shear pin in the prop. The gears will give up before those welds will.

When you weld something, it tends to draw together at the weld as it cools. The object here is to control the amount of heat and therefore the amount of draw, as well as the direction of the draw. When I make the welds I start with the first bead and there is no need to pour a bunch wire into it. Just make a good solid tack bead. Turn the shock 180° and do it again directly opposite the first bead as close to the same size bead as the first one. Allow it to cool a couple minutes and then either quench it in water or use a wet rag to remove most of the remaining heat from the part. The third tack goes right between the first two and repeat the process 180° from that one again and either let the part cool or quench it again after a couple minutes. Using this method I have never had one turn out crooked. If you start at any given point and just pour the coal to it all the way around the part until you meet up with where you started, well… there’s a good chance it won’t turn out so great.

-BenOldJohnnyRude on YouTube

January 11, 2019 at 12:31 pm #162763this is all great info since this has happened to me twice.after you weld it,what is the preferred shear pin to use? the original or something else? thanks

mn

January 11, 2019 at 12:33 pm #162764is it ok to use the bearing housing even after it has been worn down a little

mn

January 11, 2019 at 1:33 pm #162768Use a brass pin instead of the original steel one after welding the shock absorber. This will save the gearcase should you hit a submerged object or run aground.

Yes, unless the bearing carrier has been very badly damaged / worn, you can continue to use it. Remove the burr on the worn end and reassemble it. Even if it lost a bit of the bearing length, it will still be serviceable for a lot of hours as long as it hasn’t been washed out / egg-shaped by water in the gear oil.

-Ben

OldJohnnyRude on YouTube

-

This reply was modified 6 years, 5 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.