Home › Forum › Ask A Member › Phelon points

- This topic has 14 replies, 10 voices, and was last updated 2 years, 9 months ago by

jeff-register.

-

AuthorPosts

-

September 13, 2022 at 1:47 pm #265993

Had trouble with my Mark 25 this weekend. Middle of last week it ran great and had no ignition issues. This weekend…pure misery. On Saturday it seemed to be running on one cylinder. Went to clean the points and found a scratch on my paper so I realized it was time to take a closer look at the points. Found build up/crater on both sets. See photos. The manual says this can be caused by bad condensers. Is that typical? Or are there other culprits as well? Finally, are these salvageable? If so what method do you use to rehabilitate points with similar problems?

I replaced the points AND the condenser with new ones, adjusted the points to .018 and now I have nothing. No spark on either cyl. I realize it could be the coils but would they really both just crap the bed at the same time even though they both gave a great spark middle of last week? Even with the old pitted points I still had a good blue spark on the top cyl before I took everything apart.

I have heard pros and cons of files, emery cloth, etc. What works for you guys? And what’s the best solution to clean them? I’ve heard acetone before but am wondering about other opinions.

Thanks!

Scott

September 16, 2022 at 8:10 am #266114I am surprise no one has responded, so I will take a stab at it…

It is my understanding that bad condensers can cause the issue you see on your points. I clean my points with an emery board and work my way down to a folded-over fine grit sand paper. I just blow them out with a bit of air and then reset the gap.

I agree that it is unlikely both coils would go bad, but have you tested them? My bet on the “no-spark” is either the timing is off or a wire is improperly attached…

Hope that helps.

September 16, 2022 at 7:20 pm #266162You know, I did respond to this before…But somewhere between where I was typing, the website decided to make me sign in again. When I did, all my typing was gone. I said, “[oh darn it all.]” (That’s not REALLY what said, let me tell you.) Anyway, I didn’t bother retyping.

You can pretty much assume that OEM Phelon condensers are junk. I have never seen a brass-looking one test good. The points, you can clean. Testing and setting them can be a real pain, because of the poor access to the screw that holds the wires on the points. So, I just take the points right out, clean each side nicely, install new condensers and reassemble. I put the wires on the points BEFORE I mount the points back on the mag plate. Now the trick to test them and set timing, etc, is this: Disconnect the coil GROUND wires. By doing that, you can put an ohm meter or test light on the points and see when they open and close, and how much resistance there is across the points, because when the points open, there is no path to ground through the coil’s primary winding! Much easier than putzing with that hard to get point screw! When you’re done testing and adjusting, just hook the ground wires back up.

Long live American manufacturing!

3 users thanked author for this post.

September 16, 2022 at 9:34 pm #266191Some good news to report. I suspect I had a bad ground somewhere. I took the condensers/points out and re-installed them making sure tge coil wire wasn’t touching anything. Got a nice blue spark x2 and the motor started fine on the bench. Still wondering what caused the buildup on one side of the points and pitting on the other. I suspect it was a condenser that was out of range.

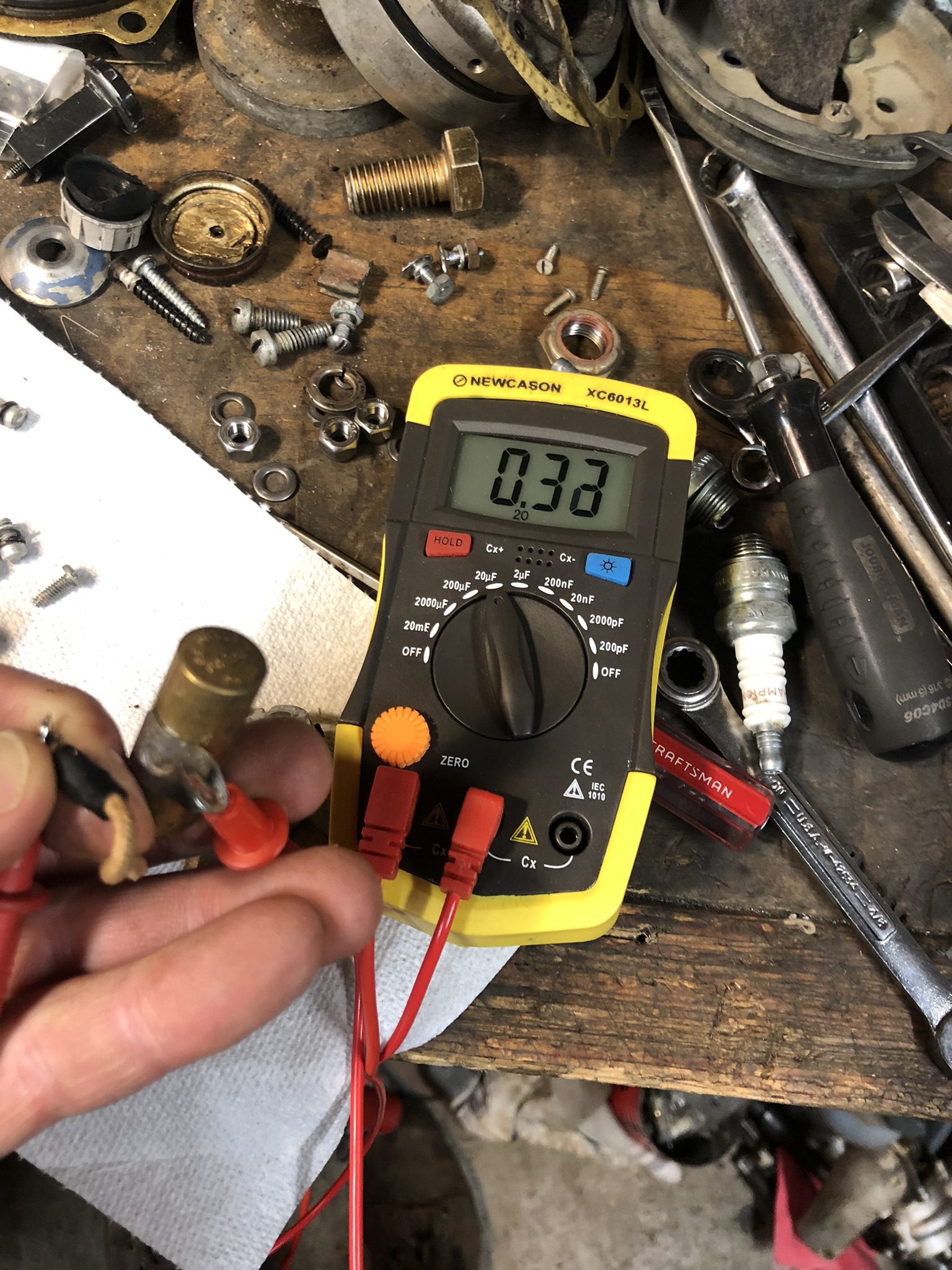

Tested the new (NOS) condenser and it had an acceptable value of .20 mF. See pics below.

Thanks for the help!

September 17, 2022 at 6:28 am #266197Hey, if you have spark, you have spark. Capacity is one test for a condenser. However, the kiss of death for most of them is the leakage test, preformed on a real magneto analyzer, like a Mercotronic or a Stevens. When I say that most original Phelon condensers fail a test, I am talking about leakage. Leakage is such a good test of a condenser that I never bother to test capacity. But again, if you have spark, you have spark.

Long live American manufacturing!

1 user thanked author for this post.

September 17, 2022 at 1:58 pm #266208You know, I did respond to this before…But somewhere between where I was typing, the website decided to make me sign in again. When I did, all my typing was gone. I said, “[oh darn it all.]” (That’s not REALLY what said, let me tell you.) Anyway, I didn’t bother retyping.

You can pretty much assume that OEM Phelon condensers are junk. I have never seen a brass-looking one test good. The points, you can clean. Testing and setting them can be a real pain, because of the poor access to the screw that holds the wires on the points. So, I just take the points right out, clean each side nicely, install new condensers and reassemble. I put the wires on the points BEFORE I mount the points back on the mag plate. Now the trick to test them and set timing, etc, is this: Disconnect the coil GROUND wires. By doing that, you can put an ohm meter or test light on the points and see when they open and close, and how much resistance there is across the points, because when the points open, there is no path to ground through the coil’s primary winding! Much easier than putzing with that hard to get point screw! When you’re done testing and adjusting, just hook the ground wires back up.

I like the idea of attaching the wires first…..and then install the points. I think I’ve done that a few times.

I also have thought of drilling a hole or grinding a slot in the edge of the mag plate….in order to allow a small screw-driver to be inserted for the final tightening. In fact; I wonder why the mag-plate was not designed with that little mod in mind?

My Stevens tester finds very few “good” older condensors when tested for leakage. Very obvious difference on the Stevens.

September 17, 2022 at 10:27 pm #266247I don’t like using a file on points as it usually scratches them leaving a rough surface, which is what you don’t want on them. When dressing them, I use progressively finer and finer wet and dry paper until they have a really smooth mirror like finish. 1200 grit is usually good for the final finish. The paper must be placed on a flat and hard surface and I find a flat steel paint stir stick works good for this. The crater doesn’t have to be completely removed but the high deposit on the other point does. Light use of a file here to remove it is OK and a fine diamond stone works to followed by the wet and dry. The points usually have a thin layer of tungsten alloy on them so you can only dress them so many times before you get into the base metal. A good cleaning with lacquer thinner or contact cleaner will remove any oil or residue from the polishing process.

Yeah, I know, people have been filing points since the wheel was invented but I’m a Virgo and my OCD really kicks in around electrical things, or just about anything else to do with a motor but they must be clean, really clean to work properly.

I notice your old cap is reading .33 uF, far above the original value but typical of old outboard caps. The values of them always seem to rise with age while the values of electrolytic caps used in receivers and amplifiers tend to drop in value with age.

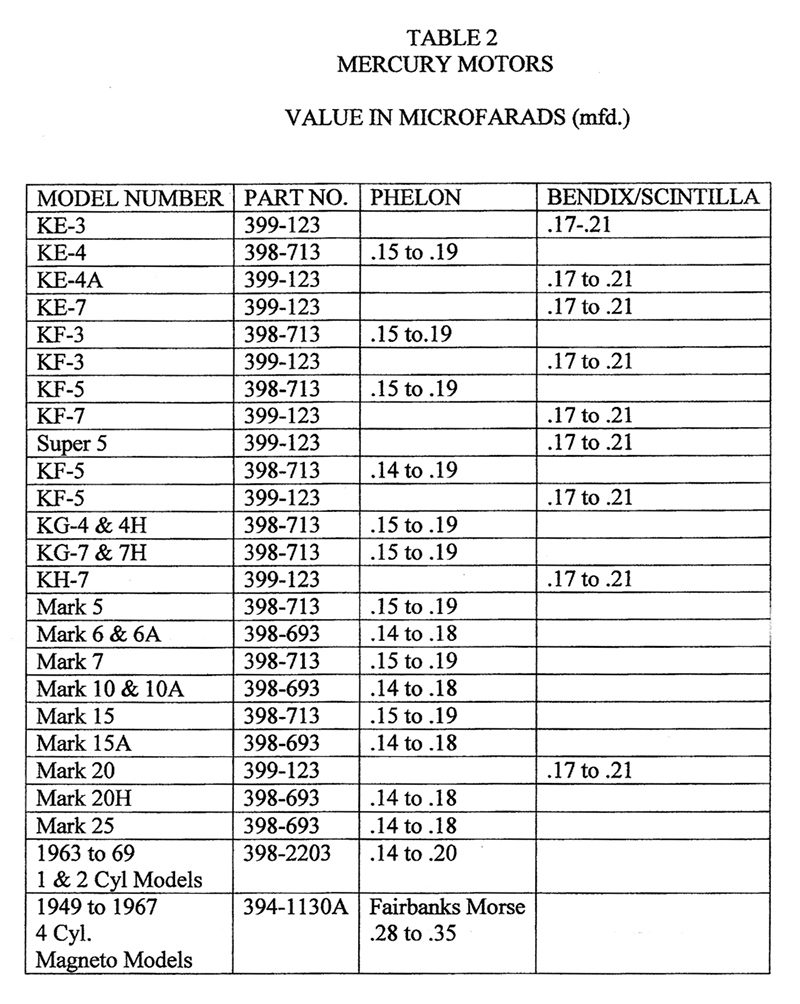

Not sure if it matters or not but your new cap is reading .20 uF, slightly more than the 10% allowable above the maximum .14 – .18 uF shown in Garry’s list for the Mark 25 equipped with a Phelon mag. The motor should run fine but the points may pit a bit quicker than if it was in the .14 – .18 range. I can’t remember what way it goes but one point will pit with too high capacitance while the other one will pit with too low capacitance. The engineers who designed the mag specified a cap with a rating right in the middle, minimal arcing or buildup on either point surface while still delivering a strong spark. If your points pit in a short time, you can always try a Vishay cap with a 0.15 uF rating to see if it improves.

September 18, 2022 at 5:38 am #266257Please follow Mumbles suggestion to refurbish points and you won’t go wrong. I have used that method successfully for over 60 yrs. I find that a points file used as a backing support for the various grades of wet and dry sandpaper works really well……like he said, finishing with 1200grit will give you a perfect mirror surface.

1 user thanked author for this post.

September 18, 2022 at 10:38 am #266263to test leakage …..see the excellent articles from mr. Mohat in the Outboarder or also available on the Western Region AOMCI site .

Building his test box is easy and has saved me a lot of grief from using good “uf tested” caps….. but failed under load at around 275Vdc

see downlables at the bottom of the hist

Joining AOMCI has priviledges 🙂

-

This reply was modified 2 years, 9 months ago by

crosbyman.

September 19, 2022 at 1:35 pm #266327Thanks for all the responses guys! Took a little time (🤣) but I got great info here as I always do!

scott -

This reply was modified 2 years, 9 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.