Home › Forum › Ask A Member › Pressure rating for OMC 1950’s tanks

- This topic has 31 replies, 14 voices, and was last updated 1 year, 4 months ago by

fleetwin.

-

AuthorPosts

-

December 4, 2022 at 5:42 pm #269665

What’s the difference between a 2 line pressure tank with the cap screwed on tight and a 6 gallon single line steel OMC tank sitting in the sun with the vent screw tightly closed? I will tell you. The 2 line pressure tank will vent to the atmosphere when the 4 to 6 pound pressure moves the relief check valve off it’s seat. The single line tank will continue to build pressure beyond that. Looking to see when a tank explodes from pressure is not a realistic concern with a properly functional and maintained tank. Either tank set up if it built to much pressure would just push the carburetor needle seat off it’s seat and gas would leak out of the carburetor vent. It’s funny 2 line pressure tanks were never an issue till the single line tanks came out. The only problem with a 2 line tank is that they are 60 years old now and would be mechanics do not understand how they work and half ass try to fix them and do not know how to test them and get mad at them when it does not work right. To bad nobody wrote to that show Myth Busters and asked the to do a comparison of safety and pressure. Would have been an interesting show. Regards Bill,

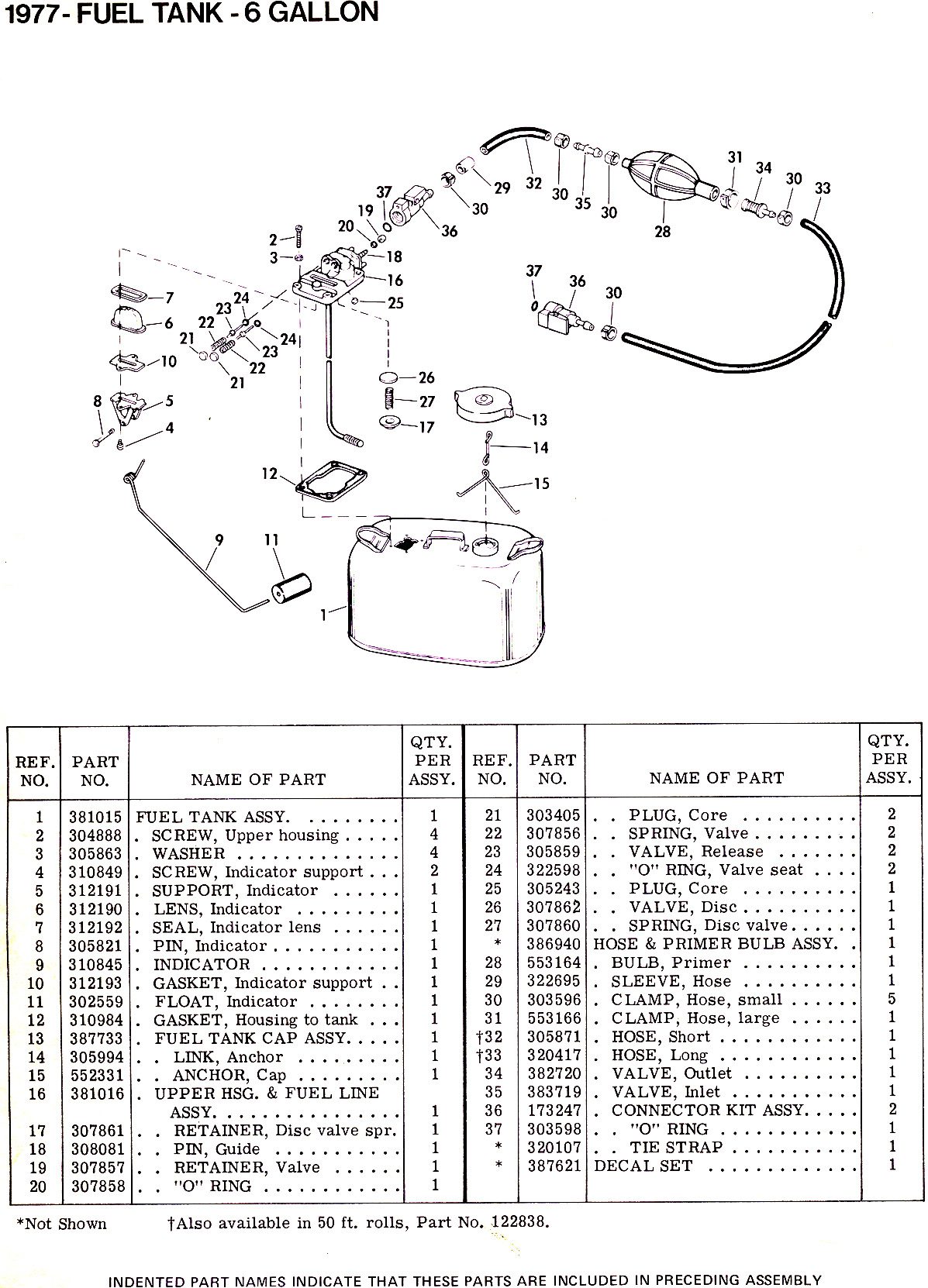

Sorry, I beg to differ. The metal single hose tanks had a pressure relief valve too. Items 26, 27, 17.

December 5, 2022 at 9:01 am #269679Thank you Frank! I knew they did, but my focus was on the twin line tanks.

Ed, thank you too! Any idea where those engineering drawings might be found? BRP probably is of no help since their entire focus was on corporate strategy.

Still waiting to hear from Duke W.

George

December 5, 2022 at 5:31 pm #269689George,

You might get lucky and find them in BRP archives. But, I afraid they are gone. There should be two part numbers, one for tank body and another for the bottom. The ‘Bill of Materials’ on the engineering drawings will be the material specification. I doubt that anyone at OMC did any sort of a fracture/rupture test. Point being many other things would have happened before tank fracture

Ed

December 5, 2022 at 5:49 pm #269690Update: Through other retired OMC top level folks I was able to speak with one of the engineers who is retired. Tanks had to conform to USCG requirements. So I went and viewed those and this is all I found:

§ 183.510 Fuel tanks.

(a) Each fuel tank in a boat must

have been tested by its manufacturer

under §183.580 and not leak when subjected to the pressure marked on the

tank label under §183.514(b)(5).I then viewed the labels on some tanks with good decals from the ’50’s and even the ones for my 1988 Johnson, and none had a pressure designation on the labels. Keep in mind that the USCG standards are updated to the latest, so maybe they weren’t in effect in those days.

So if you wish to help, please see if any of the tanks you have, Mercury included, have a rated pressure stated on the label. The USCG requirement for testing was 150% of the rated pressure.

George

December 6, 2022 at 10:42 pm #269713George, Perhaps the USCG tank rules only apply to built-in fuel tanks. Our portable tanks may be an entirely different story, maybe not even under USCG rules?

Joe B

December 7, 2022 at 5:30 am #269714Joe beat me to it. Today, and for as long as I can remember, tanks permanently mounted in a hull, have had a label that has a number of items listed, including a pressure rating. Since the tanks are often quite large, the pressure ratings are very low. We have a special device made up, that attaches to the vent fitting of a tank, and can use regulated shop air, to test the tanks. Generally, it is no more than 4 PSI, and even at that, the noises the tanks make under that pressure is scary.

Long live American manufacturing!

December 8, 2022 at 6:47 pm #269780Joe, you are correct about the test pressure. Actually, it is 3psi as stated by USCG, and I have a modern Tempo plastic tank that has the test pressure stated as being 3psi. Those pressures are used for testing leaks. But, that is not what I’m looking for and so far, even after talking to retired OMC engineers, there’s no answer to my question.

If you were to go to court to prove a point, there would have to be confirmed documentation to support your argument. So far, I don’t have that documentation that says a tank is safe up to a specified (documented) pressure. So for me to say there is a safety factor of, let’s say for example, 3 to 1, with the vent pressure being 7-8psi, the rated working pressure of the tank would have to be 24psi (3 x’s 8psi).

If we, as the Pioneering Authority, write articles, I’d like to know from my personal standing, that what I write is defendable..

You folks are the best, and I appreciate all the wonderful comments and the fact that you all are interested!

George

December 9, 2022 at 2:36 pm #269800It occurred to me that my 80s 5 gal Eagle gas cans were similar in purpose and construction to the subject OMC outboard gas cans except they do not automatically vent.I called Eagle mfg tech dept. and they told me that every can they ship is pressure tested twice,once at 10 psig for leakage and then at 25 psig for structural integrity.I know this is not sufficient to answer Georges question,but might provide a little insight.

December 9, 2022 at 5:38 pm #269806That does provide insight! I also have 2 Eagle 5 gallon cans, but from the early 1970’s. They have spring loaded caps over the fill spouts, and to fill, there is a notched bracket that engages with the handle used for pouring. That spring loaded cap acts as a vent!

George

December 9, 2022 at 5:59 pm #269812If you need more info,( I’m sure you’d ask better questions) just call them and ask for tech support.They were very responsive.

-

AuthorPosts

- You must be logged in to reply to this topic.