Home › Forum › Ask A Member › ?????? Question Johnson QD-16

- This topic has 39 replies, 15 voices, and was last updated 4 years, 1 month ago by

fleetwin.

-

AuthorPosts

-

May 27, 2019 at 11:19 am #176113May 27, 2019 at 11:57 am #176115

I have jumped around on this forum like a squirrel on crack but to clarify, I’ve kind of given up on the Johnson QD-16 at present as it DOES have noticeable scores in the cylinder walls that would seem to make it impossible to obtain good compression. I did manage to get the water pump working and it DID start but wouldn’t idle and smoked to high heaven (bun your eyes and throats smoke) after it ran a bit the compression went from 50 up to 60 but still really low from my understanding. So as I say I set this one to the side for now. The one I’m working on now is a 497 Scott Atwater . Compression felt really weak when I pull the pull rope. Checked compression and it was less than 40. Cylinder walls look great, no scratches. So I was looking for other suggestions for causes of low compression. I noticed the underneath of cowling was oily, sticky, greasy so I got to thinking maybe the crankshaft seal could be causing low compression. Even though underneath cowling is sticky oily, the engine is really clean. You wouldn’t look at it and say wow that’s a worn out piece of junk. As I’ve said I have 8 non running engines and EVERY ONE that I’ve check d compression on shows 50# or lower. (I have a 30 hp mariner on my boat that runs great and it shows 85 psi per cylinder so I’m thinking my gauge is ok. Are there any other “fixable” causes of low compression. I really do appreciate yalls patience and willingness to help

It's a jungle out there.

May 27, 2019 at 12:24 pm #176121I got to thinking maybe the crankshaft seal could be causing low compression.

The condition of the crankshaft seal will minimally, if at all, affect the cylinder compression in a two stroke motor. It’s there to maintain the pressure/vacuum cycles in the crankcase itself. The sealing capabilities of the rings to cylinder wall and the condition of the head gasket are the major players in determining cylinder compression.

May 27, 2019 at 12:53 pm #176126Ok that’s the answer I was looking for. Not the one I wanted but it gives me something to go on. I understand what tubs was saying with the re ring theory. Never anywhere in any manual for any motor do they recommend installing new rings without checking the bore to see if it’s in spec or if it’s egged so bad that you need to bore it and install oversize pistons. I KNOW this is the correct procedure …..BUT we are talking about a 70 year old engine and parts are scarce to nonexistent for internals so for the sake of getting an old low compression engine up and running for a while longer, would it be acceptable to hone the cylinder (can this be done without removing the pistons?) install new rings and see what happens? Or do you just say ok compression is too low so I have a 70 year old conversation piece? yall have been doing this a lot longer than me so I’m open to suggestions. I’ve been tinkering with painting and cleaning it while I’m debating what it will take to make it run, so it’s gonna look like it rolled off the showroom floor regardless.

It's a jungle out there.

May 27, 2019 at 1:21 pm #176127.

A "Boathouse Repair" is one that done without having tools or the skills to do it properly.

-

This reply was modified 6 years, 1 month ago by

Tubs.

Tubs.

May 27, 2019 at 1:24 pm #176128If you are planning on installing new rings, you’ll have to break the case open and pull the pistons anyway. If it were my motor, I’d pull it apart and check the bores for being round or out-of-round. If bores are within spec, then hone them, install new rings and crankshaft seals, then re-assemble. But even before that, as Tubs suggested, I’d run the motor for awhile and see if it’s just stuck rings causing the low compression. Running for awhile with modern oil and maybe some OMC Engine Tuner might clean up the rings and improve compression.

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1955 Johnson QD-16

1957 Evinrude Fastwin 18

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."-

This reply was modified 6 years, 1 month ago by

Bob Wight.

Bob Wight.

May 27, 2019 at 4:17 pm #176140Thanks for the input. On this Scott Atwater, the crank rope jammed up before I began disassembling so I didn’t attempt to start it. Since,it’s,partially torn apart I think I’ll check the bore. hone and re ring if possible. maybe I’ll get one running before too long. If it wasn’t challenging it probably wouldn’t be near as much fun

It's a jungle out there.

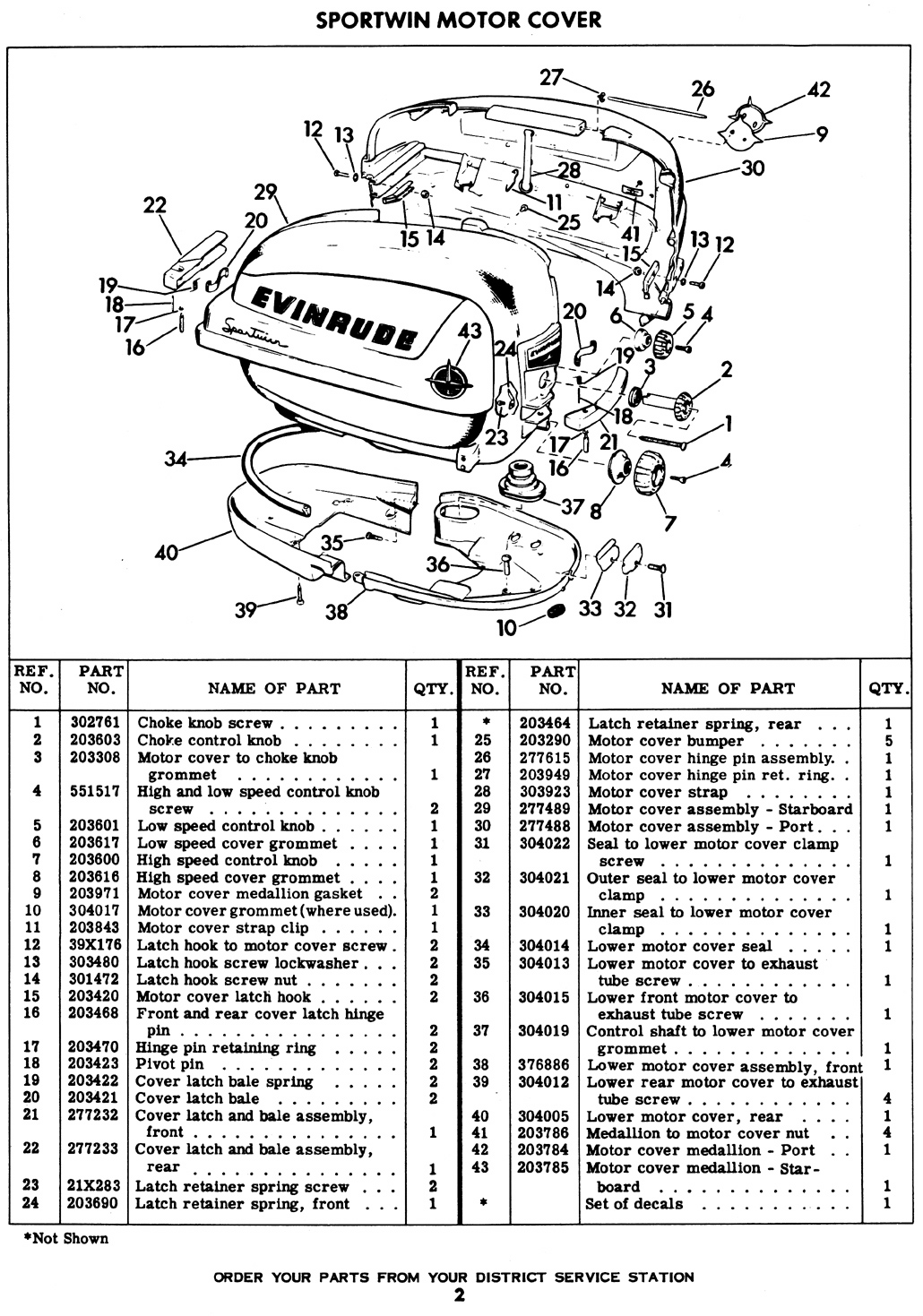

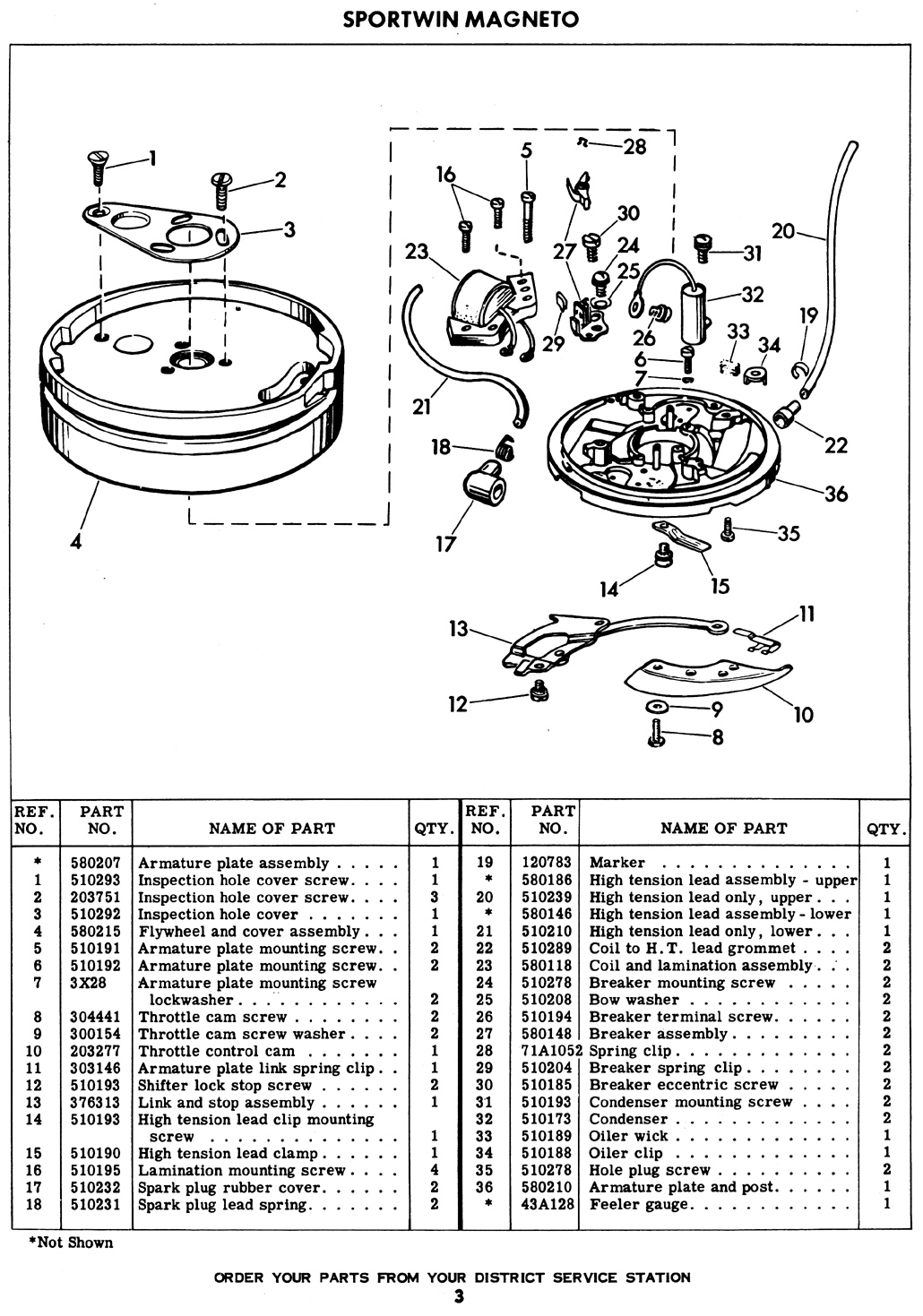

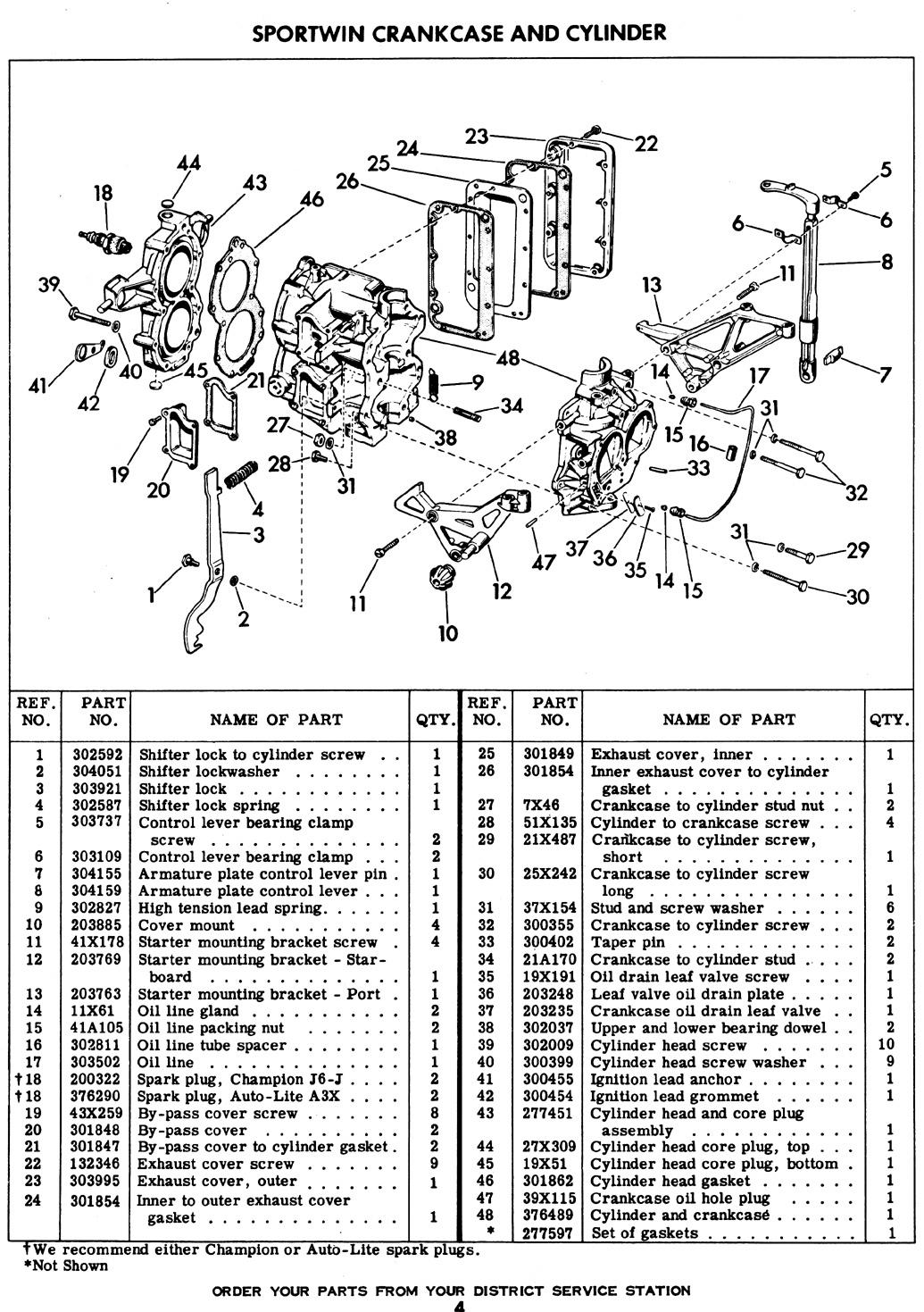

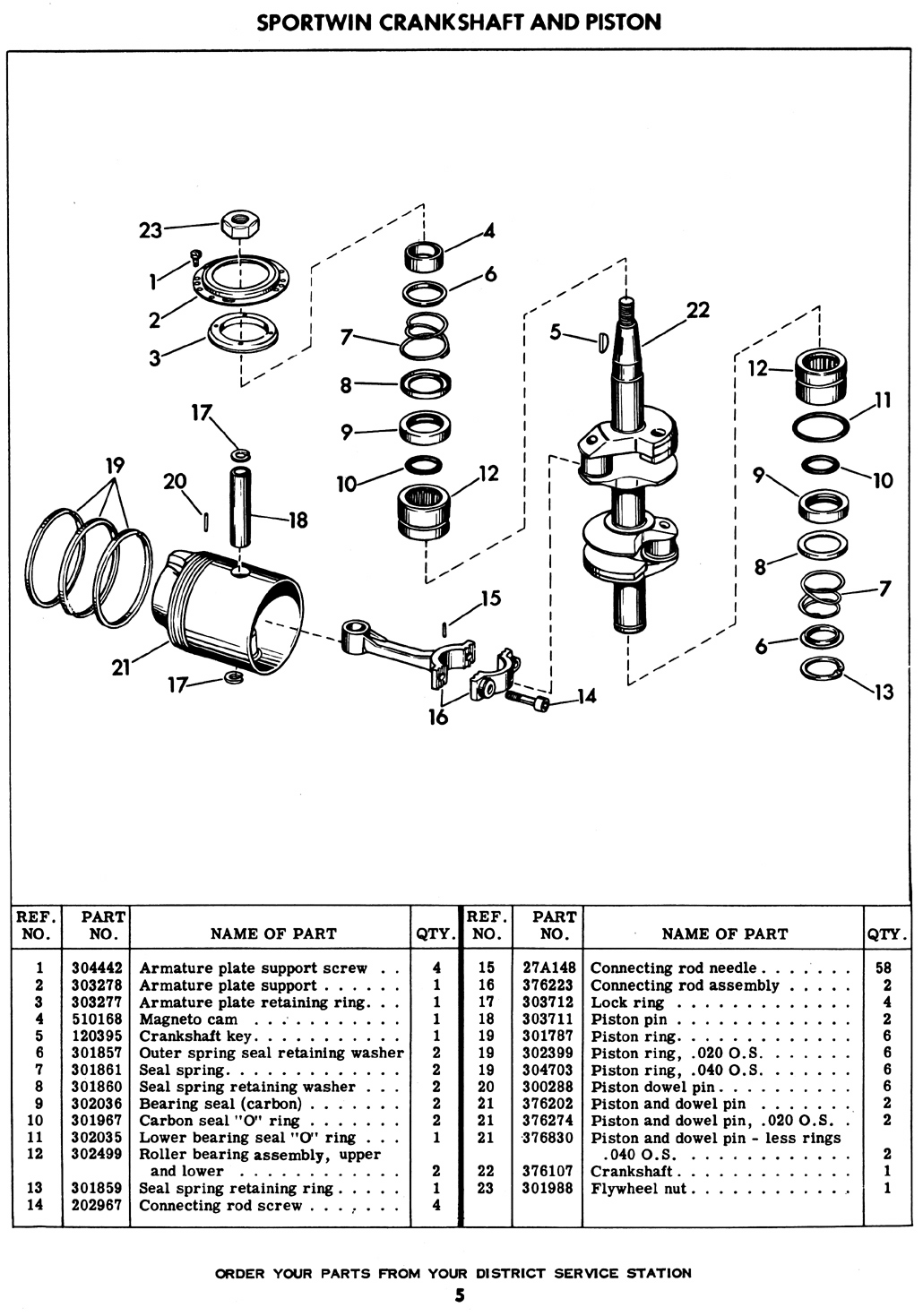

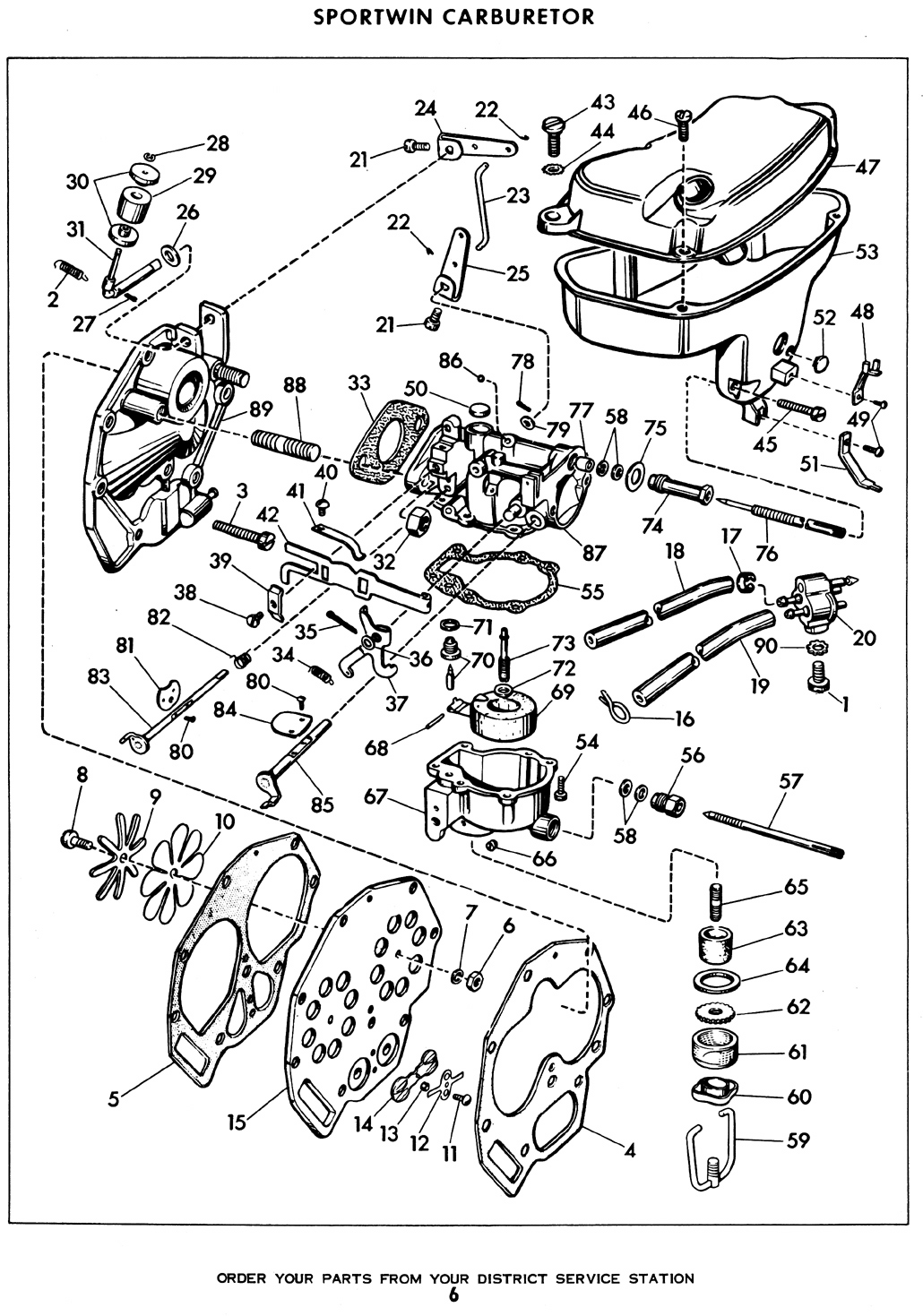

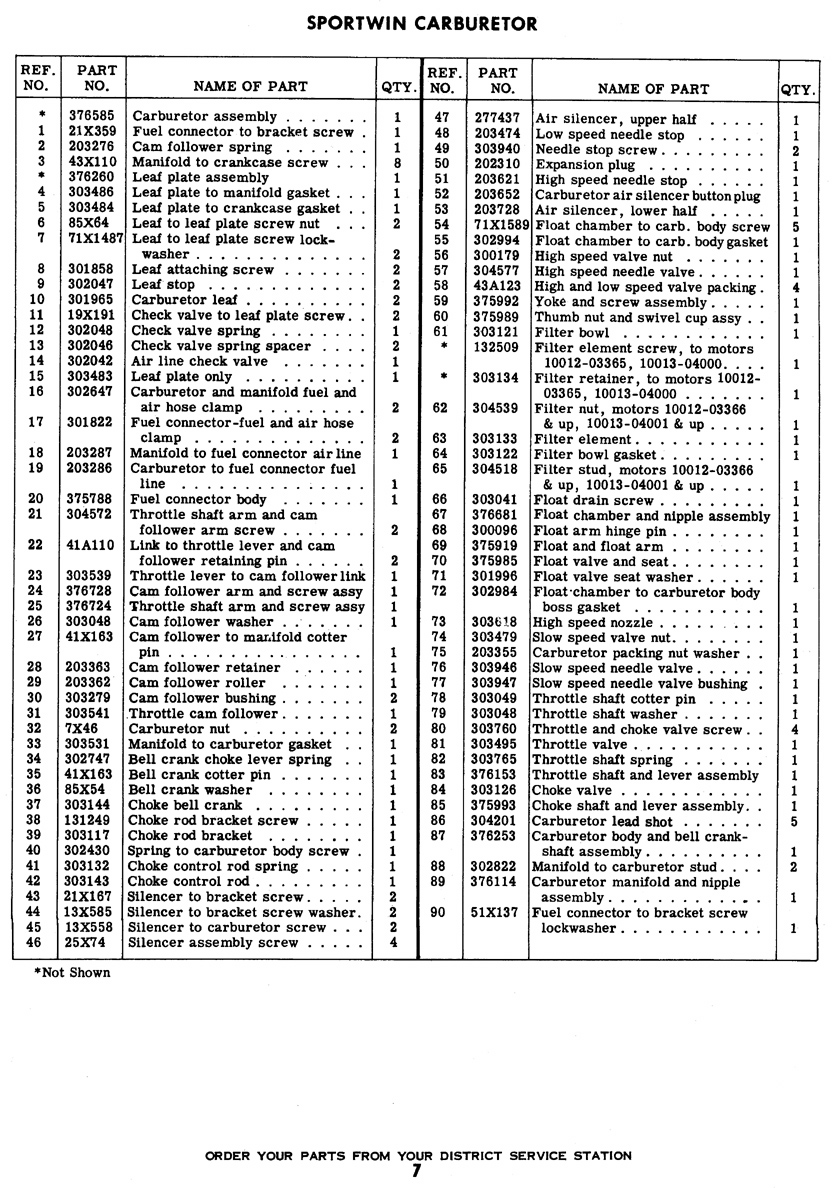

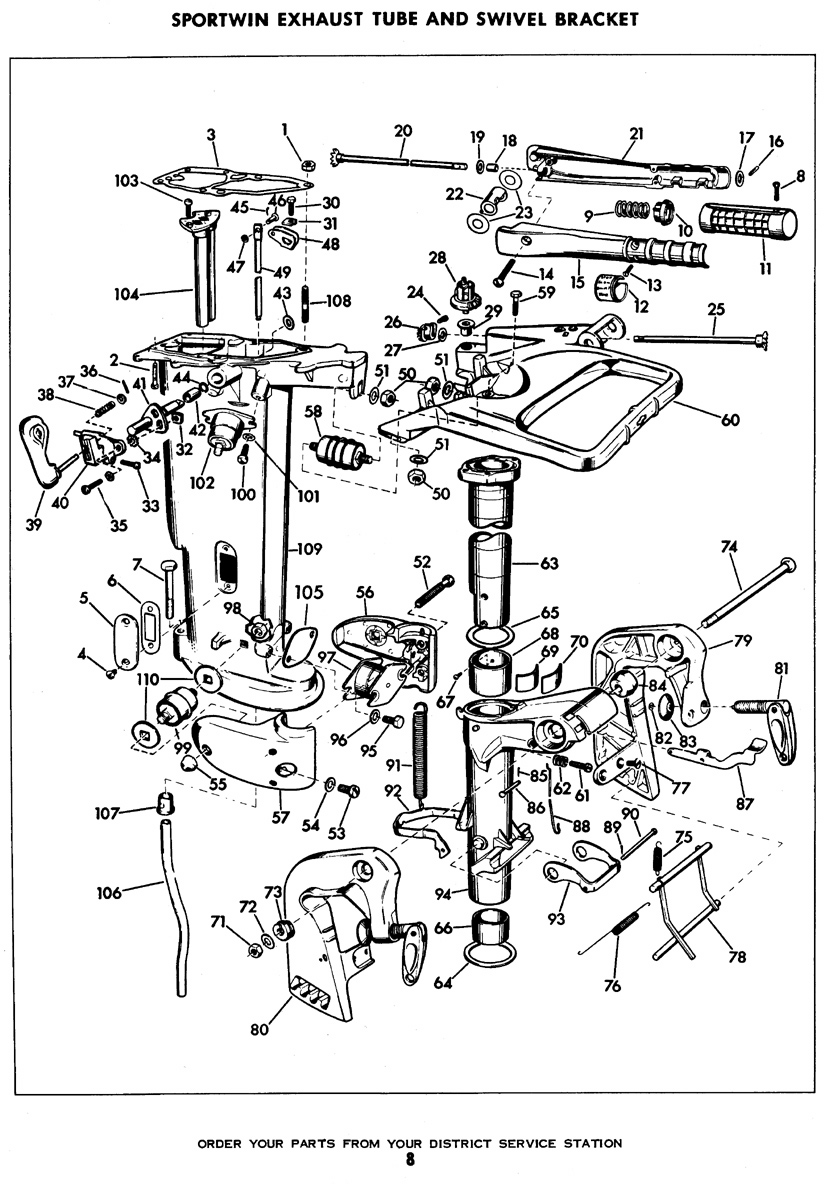

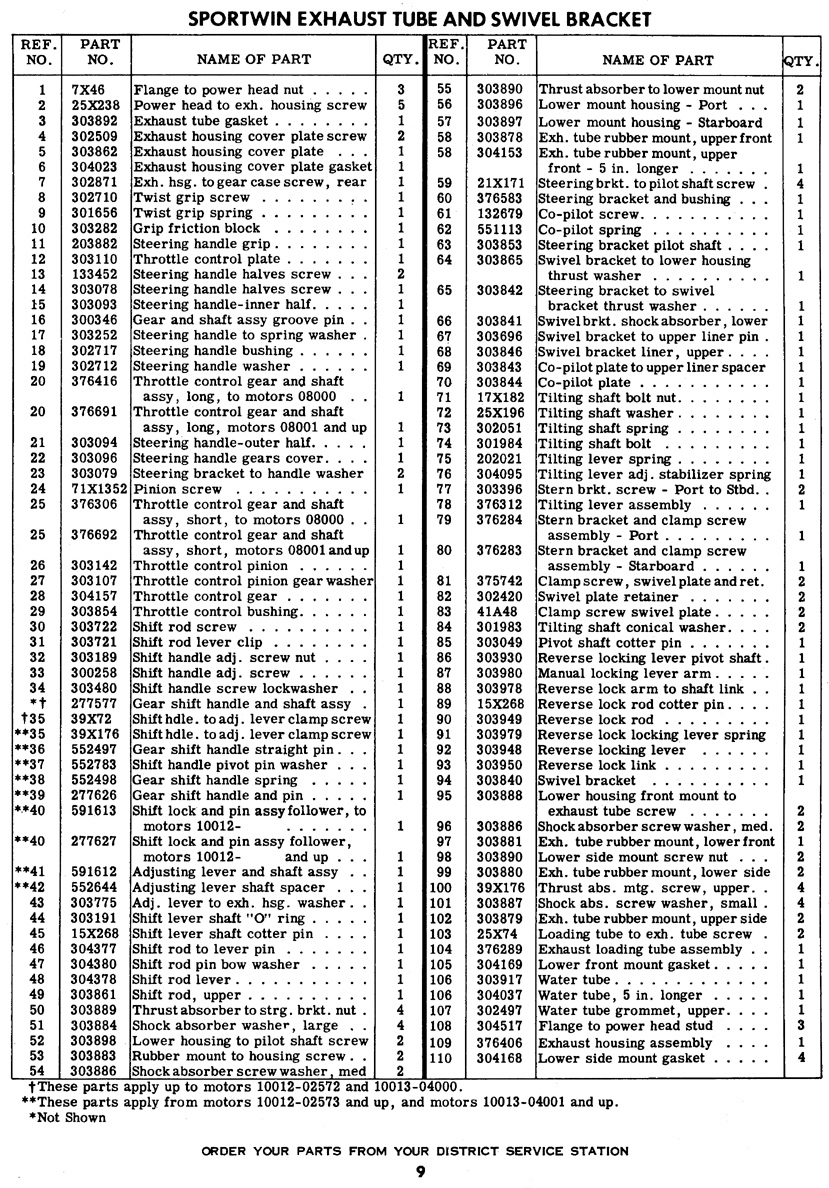

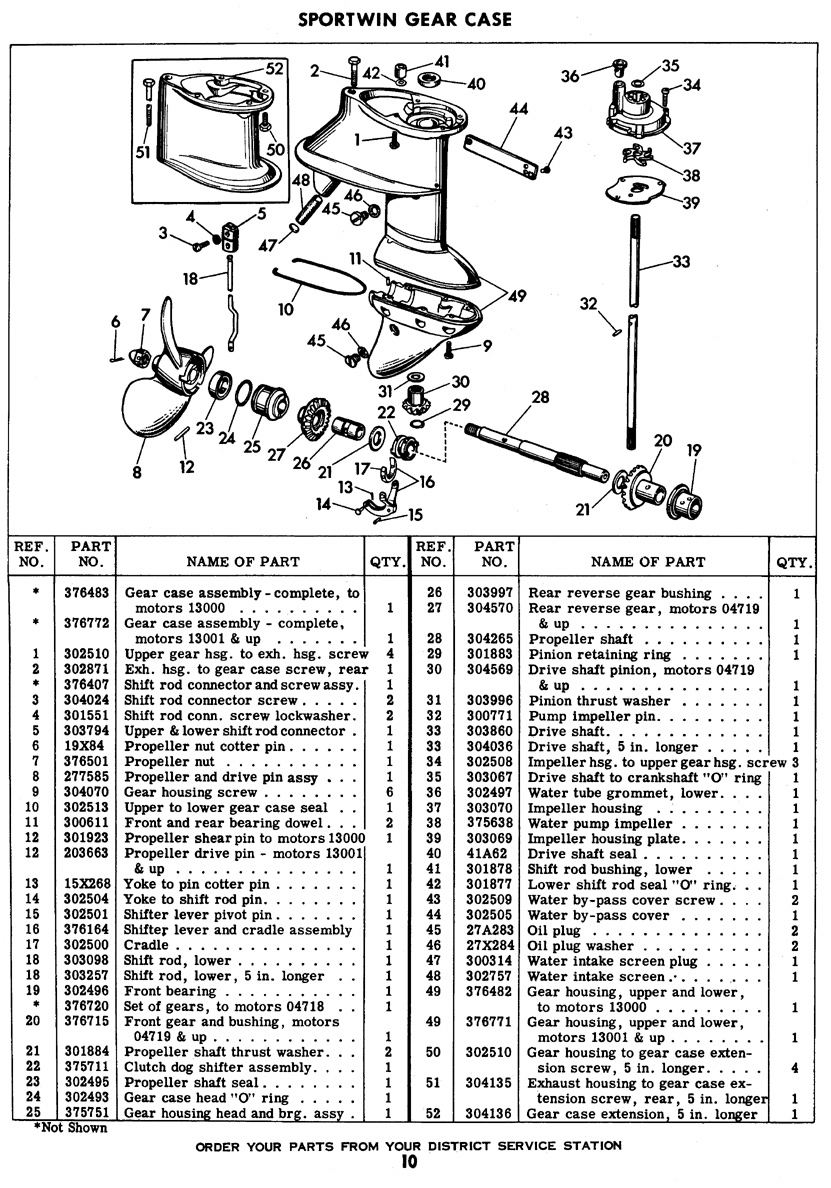

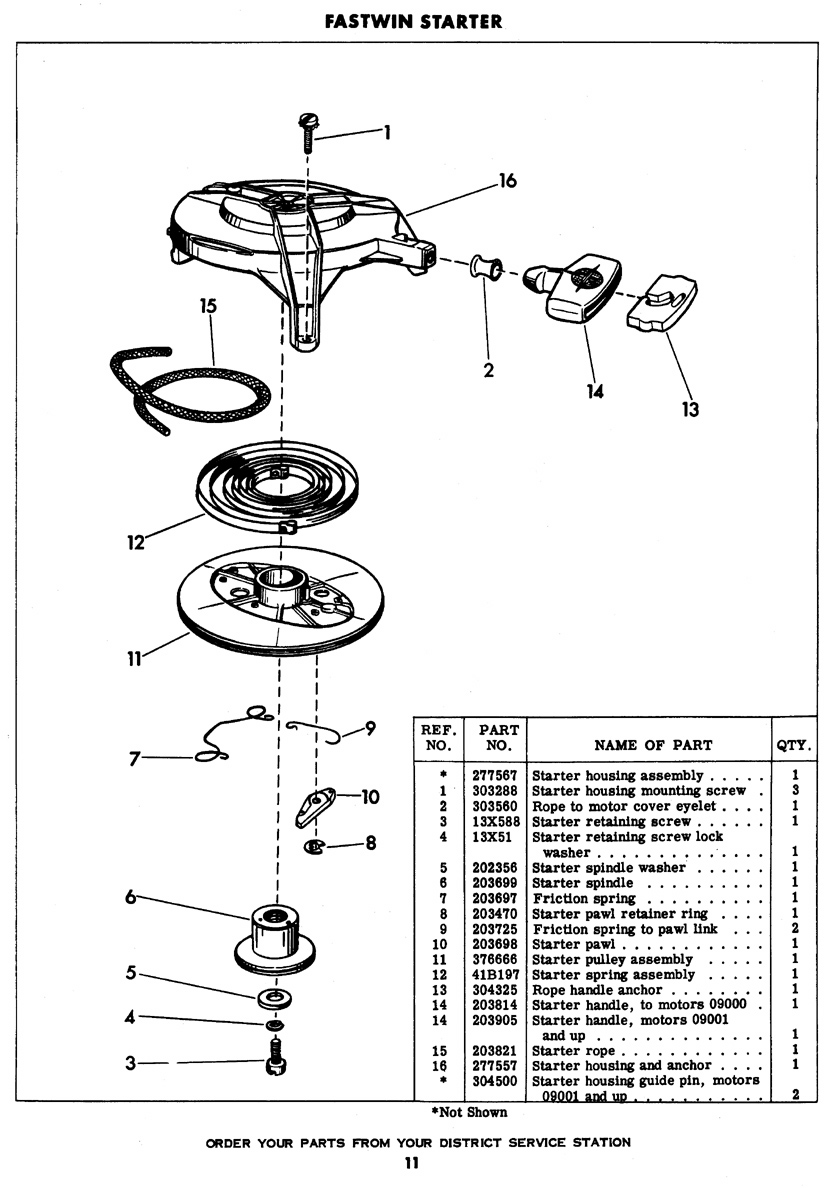

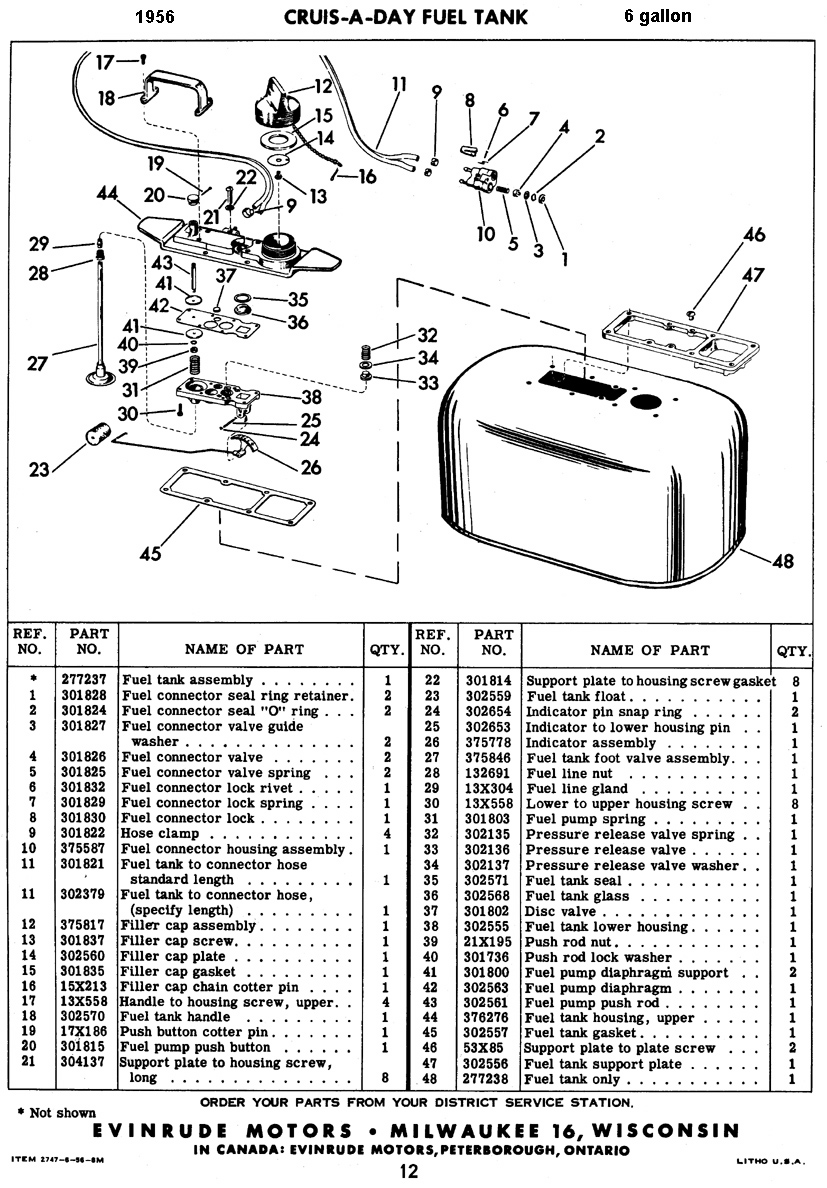

May 28, 2019 at 3:11 am #176160I don’t know what that flap of metal is in the second picture, but it is not a reed valve. I don’t have the Johnson book digitized (I’m EVINRUDE special interest group leader) This is for Evinrude’s equivalent . . . Most parts are interchanegable

-

This reply was modified 6 years, 1 month ago by

garry-in-michigan.

garry-in-michigan.

-

This reply was modified 6 years, 1 month ago by

garry-in-michigan.

garry-in-michigan.

-

This reply was modified 6 years, 1 month ago by

garry-in-michigan.

garry-in-michigan.

May 28, 2019 at 9:50 pm #176214No sir that is the picture of a Scott Atwater model 497 and it is actually a sleeve for the intake port behind the inspection plate. I was gonna see about getting rings and maybe honing the cylinder and putting new rings in and maybe help the compression a little BUT, guess what NLA there are virtually NO parts available for this engine anywhere on line. I did find and order a gasket kit so I can completely reassemble everything but not actually fix anything. No carb kit available heck can’t find a decal set for it. Pistons and rings out of the question. My paint job is pretty much complete and I’m really proud of it. But I guess I’ll put it all back together and decorate my shop with it. Next up I have a early 50’s 5 hp sea bee or a late 40’s evinrude I can tinker with. The next motor I buy I will check compression first and have something to build upon. I’ll post some pics of the Scott Atwater when I get it reassembled. May go ahead and clean the carb and fix the pull rope and see if it’ll start

It's a jungle out there.

May 29, 2019 at 4:00 am #176218Sorry – I thought it was a QD-16 Johnson . . .

-

This reply was modified 6 years, 1 month ago by

-

AuthorPosts

- You must be logged in to reply to this topic.