Home › Forum › Ask A Member › Seal Upper Crankshaft Bearing Evinrude 18 HP 1960

- This topic has 10 replies, 5 voices, and was last updated 1 year, 6 months ago by

bobw.

bobw.

-

AuthorPosts

-

September 24, 2022 at 10:47 am #266560

When doing a complete overhaul I want to make sure that the Crankshaft has proper seals in both ends. On dissembling I discovered oil in the Magneto assembly. I have now installed a new seal in the upper needle bearing. But what about O-ring around the bearing? There’s O-ring with part number #308458 on the same bearing on the 40 HP. But the 18 HP doesn’t have O-ring according to the parts diagram on marineengine and others. The Roller Bearing 377528 is the same on both models (18 and 40 hp) though. So I thought it might be a good idea to put an O-ring on the outer surface of the Upper Roller Bearing. Any comments are welcome. Thank you.

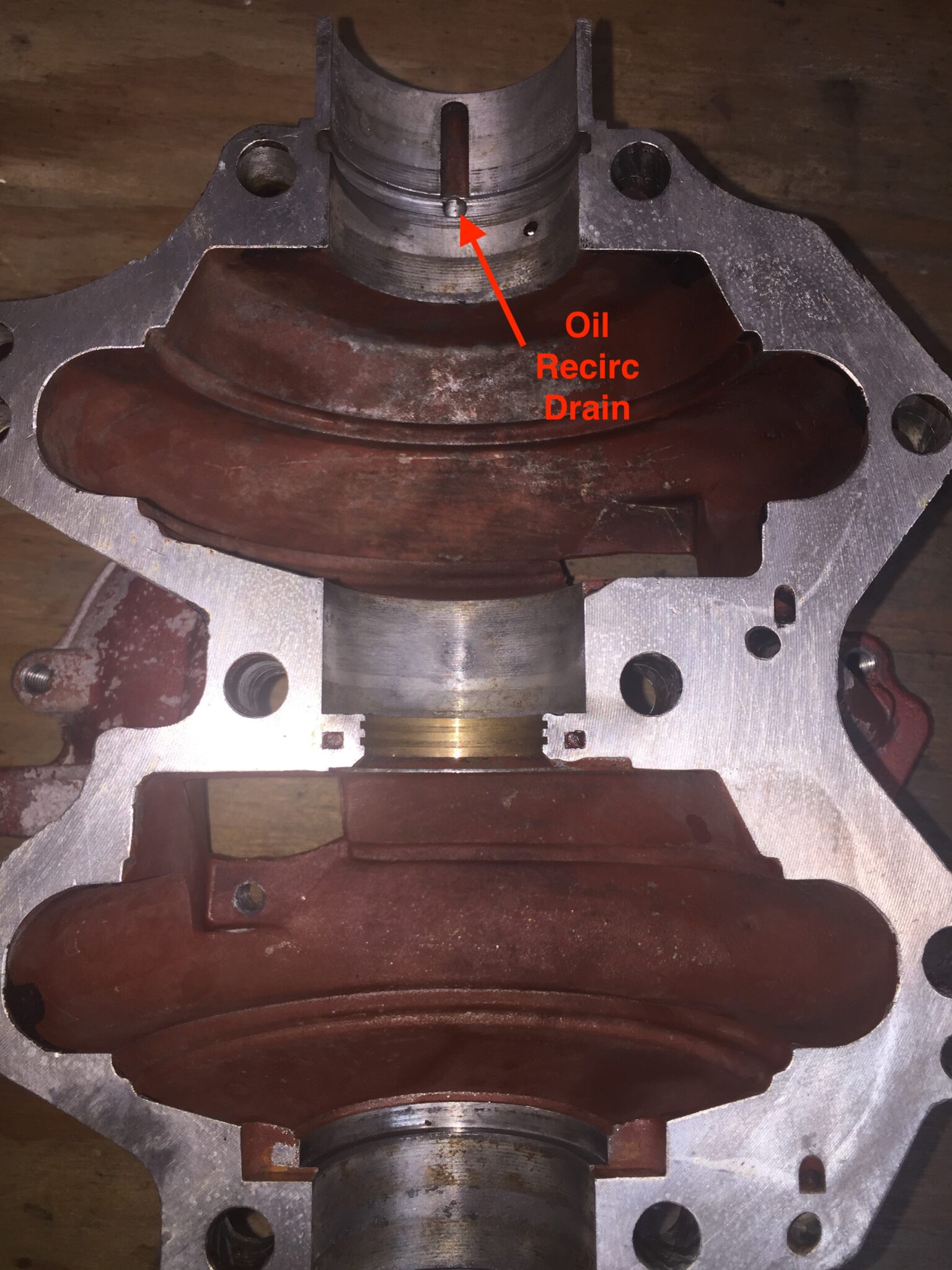

September 24, 2022 at 2:44 pm #266565The 18hp does not use an O-ring on the top bearing. There is an oil recirc system that pulls any oil seepage back into the intake manifold through a small hole in the front half of the crankcase boss around the bearing (in the groove where it looks an O-ring would go). See attached pic.

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1957 Evinrude Fastwin 18

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."September 24, 2022 at 3:08 pm #266568bobw is right on! Make sure the drilling to the intake manifold is not plugged. Some people use to much sealer on the intake gaskets and it is easy to plug up the pumping system. The pumping starts at the lower main bearing then it goes up to the top bearing through a small rubber hose. It ends up on the suction side of the reed valve. If it is plugged off at the top gas/oil mix will splash all over the points and coils.

dale

September 24, 2022 at 4:52 pm #266572OK. Many thank’s for very useful information. I wasn’t aware of this. I have to study this a little to understand the oil recirc system. I will definitely follow your advice. I might come back here with more questions to clarify my own understanding. Hope that’s OK.

It’s my first outboard project and I still have a lot to learn.

September 26, 2022 at 4:49 pm #266721This is a great question, and a much debated topic. Definitely do not use an oring, or the excess oil problem could actually be aggravated. I’m not a big fan of this system, it’s too bad they couldn’t have combined this system with an oring as well. Double protection.

September 26, 2022 at 5:36 pm #266725Hi fleetwin

Thank you very much for following up. I follow this advice, and won’t use an O-ring on the upper bearing/seal. The only seal here will be the seal inside the bearing. So I have to inspect the original seal in the upper bearing from time to time and test it for leakage. Hopefully a new seal installed today will last for som seasons in the future.

September 27, 2022 at 7:32 pm #266809I think many leaks in this area are mistakenly blamed on faulty upper seals when in fact, the oil is sneaking by between the upper bearing case and the crankcase castings.

September 28, 2022 at 1:31 am #266815To prevent any oil leaking past the bearing, you can apply a thin coat of the same sealer being used on the crankcase halves to the bearings outer surface while assembling the motor.

-

This reply was modified 1 year, 6 months ago by

Mumbles.

Mumbles.

September 28, 2022 at 2:23 pm #266838Hi. I will definitely not put an O-ring on the upper bearing, but I did put a very thin layer of Loctite 518 anaerobic sealer between the seal and the groove in the bearing where the new seal is pressed in. I sprayed just a little Loctite 7649 primer first since it might be required for the 518 sealer to work. I did this to prevent oil from travelling between the seal and the bearing groove. (Hope my English is understandable, this is not my primary language)

Wouldn’t it be a little tricky to put 518 sealer between the bearing and the crankcase halves? I’m afraid this might start getting trouble with the oil drain holes. Any thoughts on how to avoid sealing the drain holes when putting sealer between the bearing and the crankcase halves?

September 29, 2022 at 8:40 pm #266920I have often thought of doing this same thing. But, you would have to be so careful to avoid plugging the recirc groove and port, so you would have to apply it near the bottom of the bearing. Again, being careful not to get any in the bearing as well. Probably best to not apply the anerobic sealer I guess. Again, it’s just too bad that the engineers didn’t incorporate a combination of the two systems, the recirc groove and port along with an oring below it. Oh well.

-

This reply was modified 1 year, 6 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.