Home › Forum › Ask A Member › 1925 Rowboat Motor Starting Problems

- This topic has 4 replies, 4 voices, and was last updated 6 years, 10 months ago by

pm-t2.

pm-t2.

-

AuthorPosts

-

June 16, 2017 at 6:58 am #7344

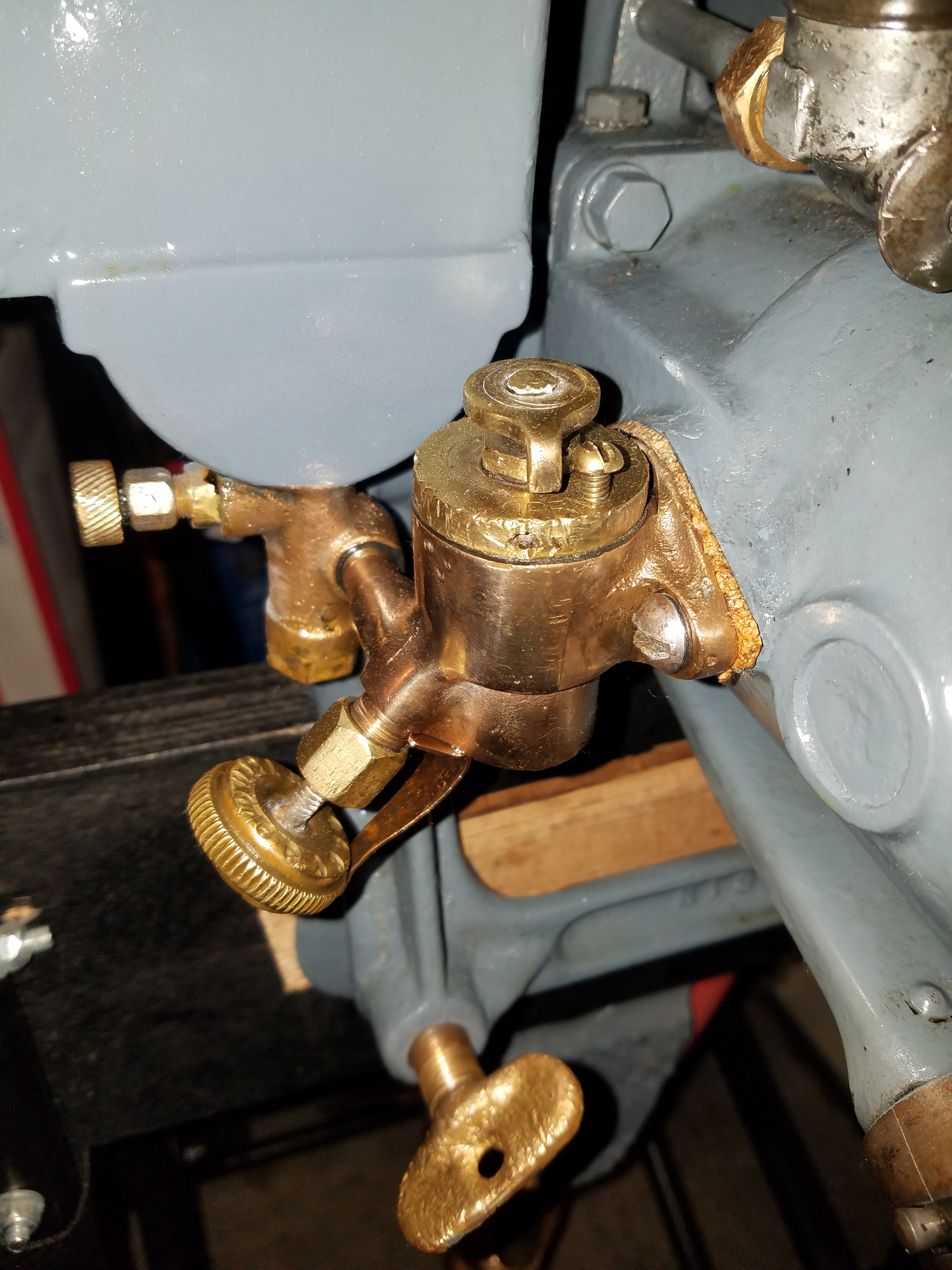

Calling all RBM owners. I finally finished putting my 1925 Evinrude RBM back together and now I am having starting issues. I bought a vest pocket guide with starting instructions but the book says refer to the tag on the motor for carb settings. As you can guess there is no tag. I have tried different air and fuel settings but all I get is backfires and 3 second runs when I try to start it. Can anyone tell me the initial settings to start this beast? Also can you tell me things to look for such as bad point settings etc? Any help will be greatly appreciated. MP

“The ultimate measure of a man is not where he stands in moments of comfort and convenience, but where he stands at times of challenge and controversy.” ― Martin Luther King Jr.

June 16, 2017 at 10:57 am #59767.

sounds like a fuel issue

when you wiggle the flywheel and you hear the valve ( popping )

then you know at least the carb works and sucks fuel into the crankcase.

carbs settings depends on the condition of the engine and

a little experience

meaning ; instructions in the book gives you an idea and applies to a brand new motor, or…..

but instructions of the position of the timer don’t change I guess

.June 16, 2017 at 11:33 am #59769I don’t see any spark plug wire on the motor. Can we assume you are using a buzz coil, and not a low tension coil? If you’re using a buzz coil, that should eliminate any questions about the ignition. If you’re using something that only gives a single spark, consider going to a buzz coil until you work out any other issues.

There are two valves in that carburetor. One is the needle valve, the other is the poppet valve. The poppet valve should have a return spring on it to close it. If the poppet valve and seat are worn, fuel will leak and flood the motor when you try to start it. Try this: Gently close the needle valve and try to start the motor until all firing stops and fuel is cleared from the motor. Then rope it over a couple more times to make sure. Finally, open the needle valve 3/4 turn and immediately try to start the motor. If the results are better, look into reseating the poppet valve.

Keep us posted…

Tom

June 16, 2017 at 11:40 pm #59800quote Tom Manley:I don’t see any spark plug wire on the motor. Can we assume you are using a buzz coil, and not a low tension coil? If you’re using a buzz coil, that should eliminate any questions about the ignition. If you’re using something that only gives a single spark, consider going to a buzz coil until you work out any other issues.There are two valves in that carburetor. One is the needle valve, the other is the poppet valve. The poppet valve should have a return spring on it to close it. If the poppet valve and seat are worn, fuel will leak and flood the motor when you try to start it. Try this: Gently close the needle valve and try to start the motor until all firing stops and fuel is cleared from the motor. Then rope it over a couple more times to make sure. Finally, open the needle valve 3/4 turn and immediately try to start the motor. If the results are better, look into reseating the poppet valve.

Keep us posted…

Tom

Tom,

I am using a model T coil to run the motor. I will check the poppet valve and post again“The ultimate measure of a man is not where he stands in moments of comfort and convenience, but where he stands at times of challenge and controversy.” ― Martin Luther King Jr.

June 17, 2017 at 12:00 am #59801I’ll suggest that you look at the clearance on your top main crankshaft bearing if you are getting backfires or only sporadic brief runs out of it. Also, my experience has been that with the coarse thread on those fuel needle valves, even 3/4 of a turn might be too rich. And the coarse thread also makes them very touchy with a narrow band of where it runs the best. I’d suggest no more than 1/2 to 5/8th’s of a turn, and yeah 1/8th of a turn can make the difference in that motor.

If the crankshaft exhibits any amount of side-play between the crank and bearing – your only answer is to re-bush the crankcase. Fortunately, your motor is of the three-piece crankcase design; you can usually get away with re-bushing the upper journal, and don’t have to tear apart the entire motor to do it either.

Poppet valve needle should be about one turn out from closed.

Pay attention to what Tom Manley said about the poppet valve and seat. You can lap the valve and seat with a lapping compound made up from a mixture of toothpaste and Comet cleanser.

Hope this helps. If it doesn’t – sorry, but I’m kinda useless for anything else.

Best,

PM T2 -

AuthorPosts

- You must be logged in to reply to this topic.