Home › Forum › Ask A Member › 1939 Evinrude Elto Ace water pump.

- This topic has 6 replies, 3 voices, and was last updated 5 years, 8 months ago by

garry-in-michigan.

garry-in-michigan.

-

AuthorPosts

-

August 2, 2018 at 3:20 am #10734

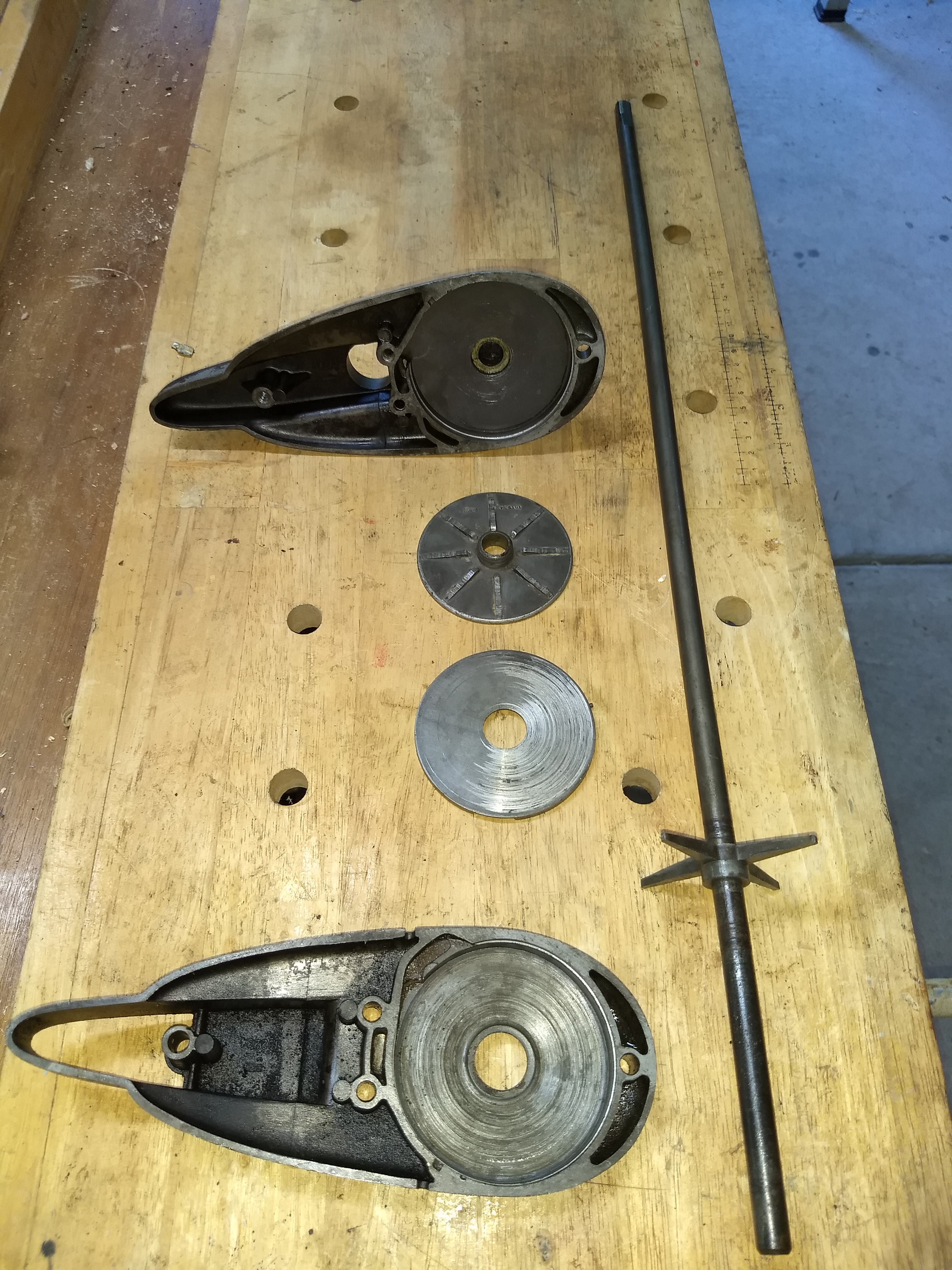

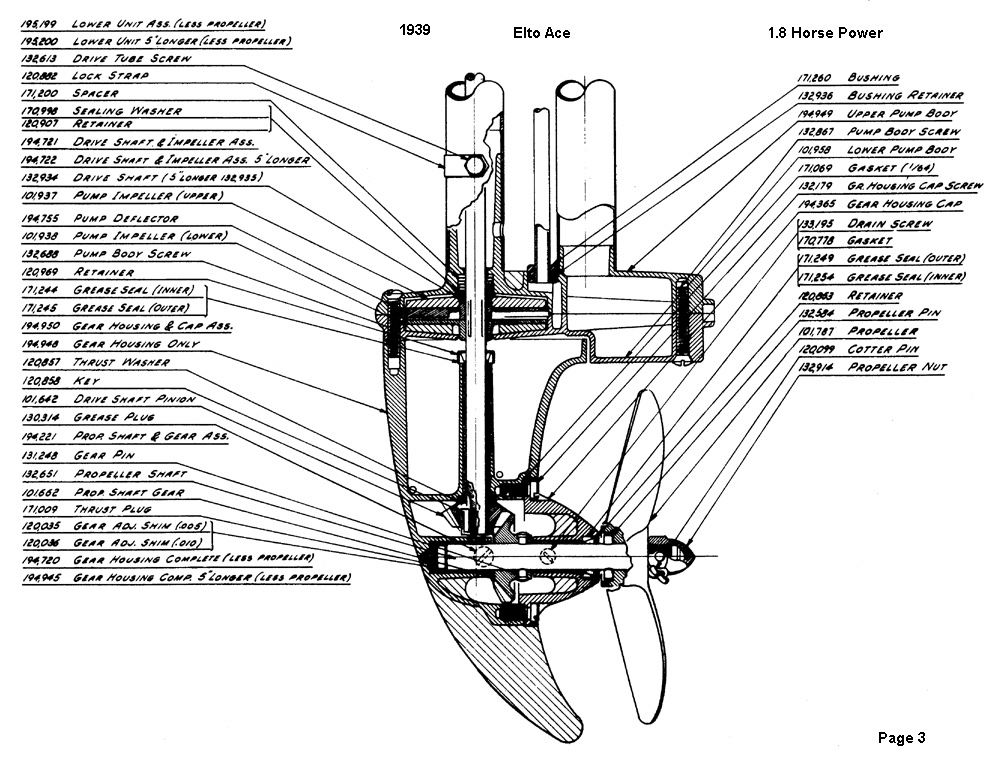

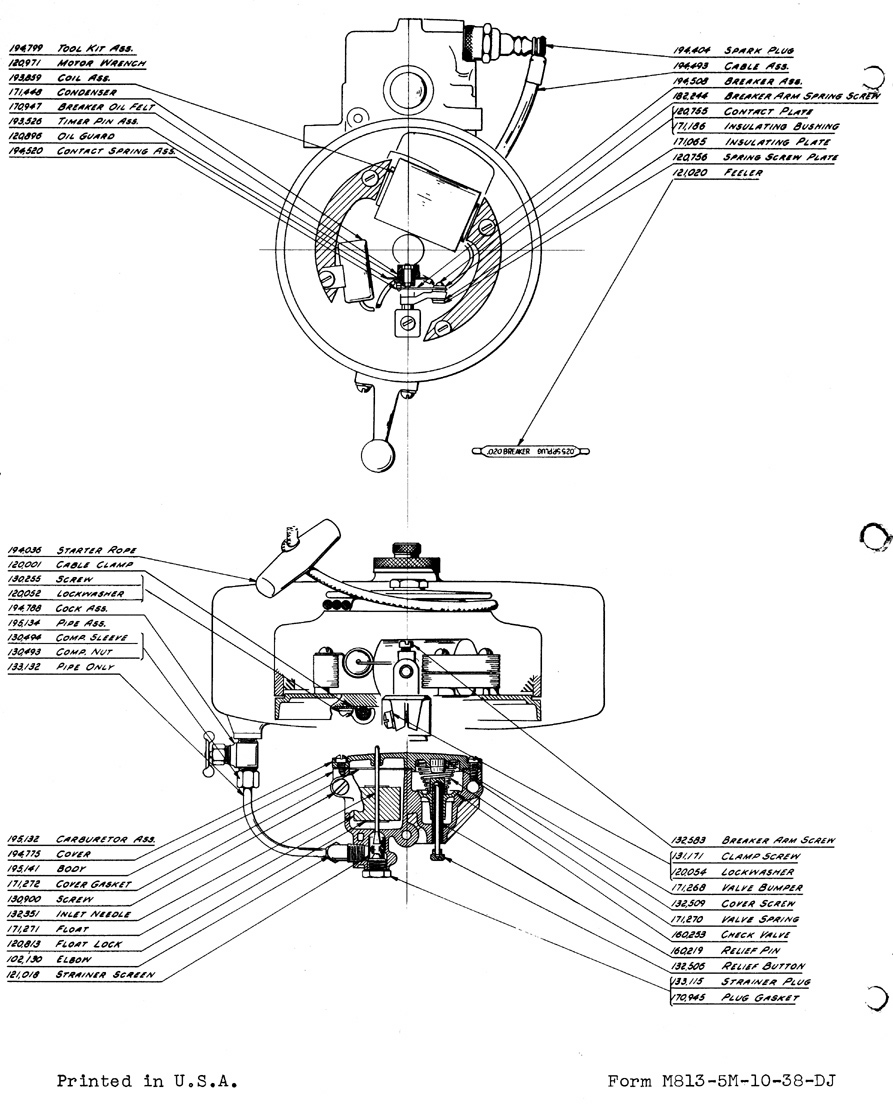

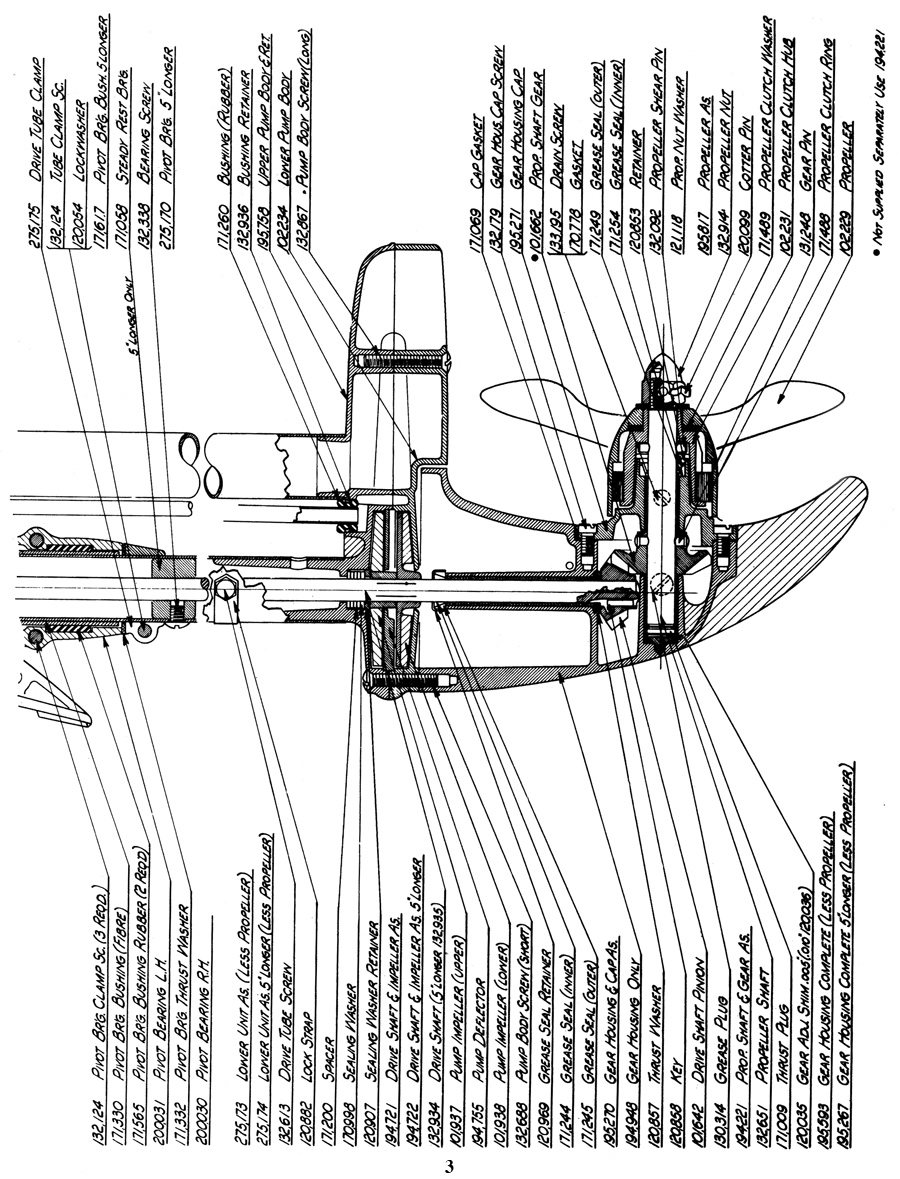

I am trying to restore my great grandfather’s outboard. My dad had it in the attic for years and told me it was air cooled. I took it apart and found the water tube caked with 50 year old mud. I cleaned it out, gases it up and was thrilled to find that it started right up and weakly pumped water. Today, I took apart the water pump and discovered the lower impeller is very worn.

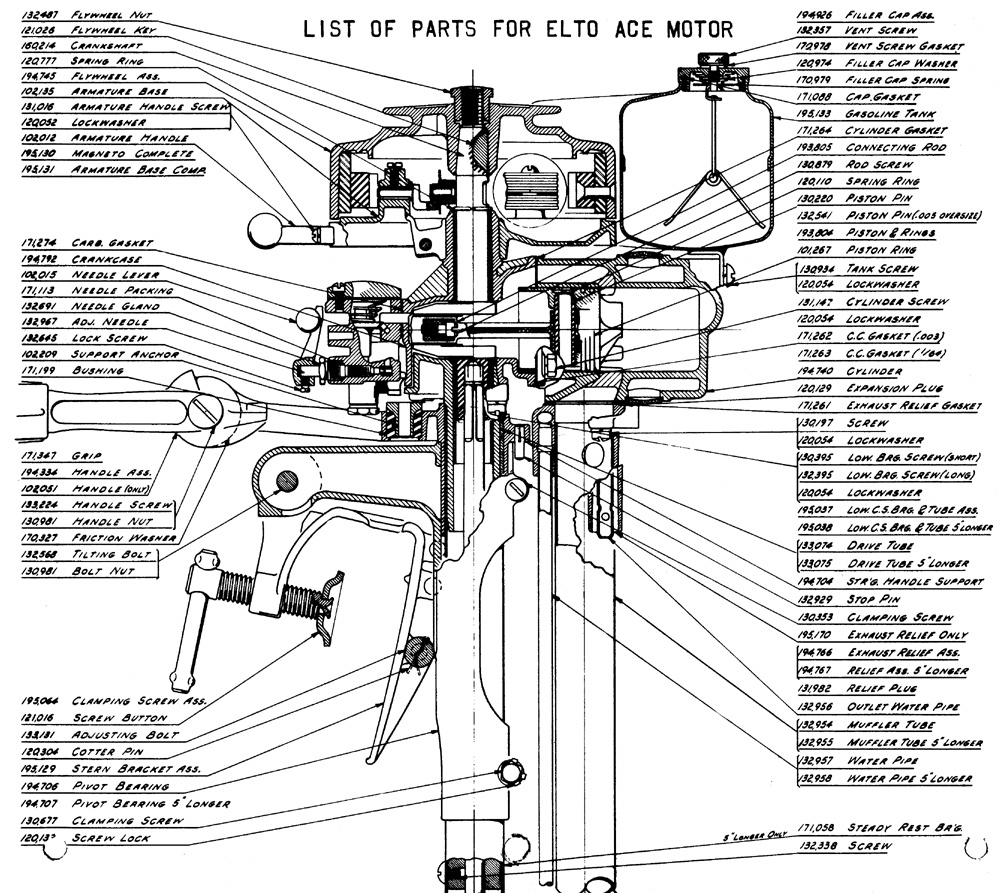

I am not sure what to do. Is there a place to get these? Is there a substitute?

Also I cannot figure out how the lower impeller spins. It does not seem to be touching the drive shaft. Does it just spin on friction from the flange on the bottom of the upper impeller (which looks to be welded to the shaft)?

August 2, 2018 at 3:22 am #80538Note. Lower impeller is an alcoa 101934

August 2, 2018 at 2:09 pm #80543Actually–it looks pretty good. Should work ok. I wonder if the water tube to the head got clogged as well?

Also, running in a tank or barrel, the water exiting looks sporadic until the spark is advanced and increases speed–August 2, 2018 at 4:57 pm #80549Actually not good – It should be tight on the shaft and have NO metal to metal contact. The bronze bushing in the gearcase that supports the driveshaft is excessively worn. Drilling and taping the bottom of the shaft for a stainless steel screw filed off to get the proper clearance will compensate for the ware. Those old cork seals were only marginally effective. Modifying the gearcase to accept modern seals is easier said than done, but possible. Use John Deere Corn Head Grease for lubrication. It is more water tollerent. You may find a good used pump impeller – OR – find some one with a 3D printer that could duplicate that lower impeller for you . . . 😉

Later model Elto Ace used this gearcase. It was also used on the Evinrrude Sportsman.

August 2, 2018 at 10:29 pm #80575

August 2, 2018 at 10:29 pm #80575Gary

Thanks for the Schematic. I looked all over for one on google and could not find one for the ace

I actually have a 3D printer. I was considering drawing up the part and printing it, but I figured that the plastic would not be strong enough. I guess I could print the collar a bit thicker than the original metal and pin it to the shaft like you suggested. Would you recommend ABS, PLA or some other material? Probably print with 100% infill?

When I pin it I should ensure a small gap so no moving parts come in contact…. correct?

August 3, 2018 at 8:11 pm #80624I did print an impeller in ABS. It is pumping water again. I am curious how it will hold up with use.

August 4, 2018 at 6:25 am #80636with no metal to metal (or Plastic) contact it should do well, as long as you don’t use your motor to dig channels through sand bars . . . 😆

-

AuthorPosts

- You must be logged in to reply to this topic.