Home › Forum › Ask A Member › 1956 javelin 30hp

- This topic has 22 replies, 7 voices, and was last updated 5 years, 6 months ago by

clemg.

-

AuthorPosts

-

September 16, 2018 at 6:53 pm #82980

Thanks for the great info!!!

September 16, 2018 at 8:04 pm #82981Would tcw3 oil on bearings or 105? When reassembleing the power head. Would 3m847 be used on top and bottom seals of the crank and crank case halves?

September 16, 2018 at 8:25 pm #82984I personally use assembly lube on my bearings when I install them (Lubriplate 105). If it is a closed bearing (you don’t need the 105 to hold the needles together), and you know you are running it right away, dunking it in TCW3 should be fine. Everyone has their method.

I used 3M847 alone on my crank halves for many years. I have recently swapped to using an Anaerobic Sealer for the metal to metal connections. The 3M847 has fillers in it, so I prefer to use it on my split gearcases and use either the Dealer Brand of Anaerobic Crank Halve Sealer of you choosing, or the more common Loctite/Permatex 515/518. I feel more secure that there will be no crank leaks, but that’s just me.

On crankcase halves that have a spaghetti seal, I put a very thin bead along the spaghetti seal groove to seal/hold the seal, and use Loctite on the metal to metal mating surfaces.

September 16, 2018 at 9:23 pm #82991Are there any torque specs available for 30hp javelin?

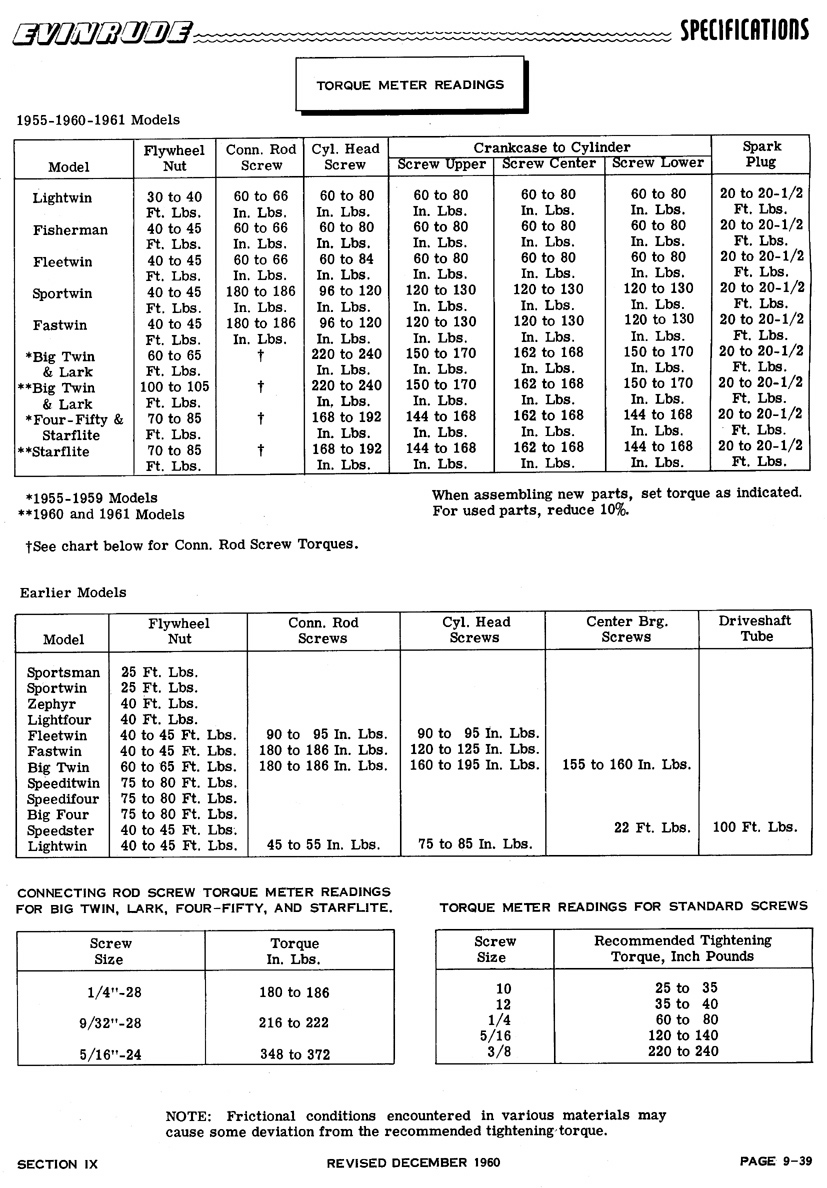

My book only covers 1957 35hp javelin.September 16, 2018 at 9:40 pm #82996Not sure what size the rod screws are, thinking they are 1/4". If so, they are 180-186 INCH pounds. 9/32" are 216-222 inch pounds. Everything else is same as the ’57.

September 16, 2018 at 9:42 pm #82997September 16, 2018 at 10:00 pm #83003Thanks a bunch!!!

October 4, 2018 at 9:26 pm #83998Clemg, What did you finally do to take up this bearing looseness? Replace the wrist pin and rod bearings? I don’t see the answer to your original question. Thank you.

October 9, 2018 at 7:35 pm #84201Sorry I took so long to respond!!

I ended up putting new pistons,rings,wrist pin bearings,connecting rod needle bearings in. Just put the case back together and no piston slop at all. Had a machine shop clean up cyclinders and all is good so far. Clemgquote OLCAH:Clemg, What did you finally do to take up this bearing looseness? Replace the wrist pin and rod bearings? I don’t see the answer to your original question. Thank you.October 9, 2018 at 10:45 pm #84212Excellent, Thank you. Did you get parts from Club members or Ebay, etc. These RDE18s are a favorite of mine. I have 3 at last count..

-

AuthorPosts

- You must be logged in to reply to this topic.