Home › Forum › Ask A Member › 1957 Evinrude Fleetwin 7.5 Water Discharge is HOT

- This topic has 12 replies, 5 voices, and was last updated 5 years, 11 months ago by

boeing707100.

-

AuthorPosts

-

May 25, 2018 at 3:28 pm #10039

Hello!

Completely went through this Fleetwin. Points, coils, condensers, plugs, wires, carb. rebuild, tank, lower unit (seals, water pump).

It runs beautifully, like a clock. The only thing I’ve noticed is that the water discharge from the pump is pretty hot, even when running in cold lake water. The power head is cool. Is this normal for this motor? My other vintage motors discharge warm water, but not hot. I just don’t want to blow it up.

Thanks,

Tony

May 25, 2018 at 4:57 pm #76706As long as the powerhead isn’t overheating, I wouldn’t be too concerned about it but you may have a restriction somewhere in the system. Some of these motors sold in Northern areas came with a restrictor inserted in the water tube right above the pump to help keep the temperature up while operating in cold temps. Without a thermostat to control the temperature, they would tend to run too cold.

I doubt if the guys in Florida have ever seen one of these restrictors, like this one installed in a ’55 Johnson CD water tube.

May 25, 2018 at 7:14 pm #76714Thanks, Mumbles! I enjoy your YouTube videos! You have some very pretty 50s OMCs.

Does the insert come out? After I drop the lower unit, do I just remove the water pump housing (the 4 slotted screws) so I can take a look?

Thanks again,

Tony

May 25, 2018 at 7:40 pm #76716Is the exhaust housing hot also? Does the water discharge appear to have the normal amount of volume/spray? Any evidence of a prior overheat? I remember a similar sort of complaint about a 10hp…

Are you sure you used the correct powerhead base gasket? There are a few different style gaskets for the various years, the wrong one will bolt up, but will cause cooling issues.

I’m assuming this engine is new to you and you never ran it before servicing it, correct? It is kind of hard to advise here, but it is clear that you feel something is wrong. So, I guess I would go ahead and pull the powerhead/gearcase and check for common issues such as crushed water tube, plugged impeller housing vent, improperly sealed impeller plate. Did you use an OEM impeller or aftermarket? Once apart, you can check for the water tube restrictor and confirm that you have installed the correct base gasket….

I suppose you could have a bad head gasket, but that seems unlikely without causing the powerhead to overheat along with running issues. A bad inner exhaust cover seems unlikely for the same reasons…May 25, 2018 at 8:34 pm #76722All parts were OEM and purchased from the same vendor – http://www.vintageoutboard.com. The used the power head gasket that came with the kit. The motor did not run prior to the service. It was a mess.

I’ve done a few of these now but never had any negative results to this point.

The discharge stream seems strong compared to others I’ve owned. The exhaust housing is hot, also. Not smoldering, but hot. The power head is cool. The motor is fairly new to me, I’ve only run it a few times. It runs great, but I’d like to head this off at the pass, before I sustain any permanent damage.

Regarding the improperly sealed impeller plate. Where should the sealant be applied? I can’t remember where I applied it, but would like to get it right when I put it back together.

Thanks much for the suggestions. I will take it apart and look it over.

May 25, 2018 at 9:26 pm #76728Well, I doubt the impeller plate is at fault, but surely worth checking while you have it apart. It is very important that the SS plate be well sealed to the gearcase housing, or the engine will pull exhaust through that joint instead of water at higher speeds. Sometimes the thin aluminum under the plate gets corroded/eroded away causing a leak as well. This area is best sealed using the OMC "type M" sealer which squeezes from a tube. The stuff is a little messy but dries quick and hard. I think it also goes by "847" if bought from Loctite. I would not use any sealer in between the aluminum impeller housing and the SS impeller plate, just clean the mating surface of the aluminum impeller housing and install it "dry" against the SS impeller plate. Using sealer in this area could weep into the area the impeller spins in and hamper its performance.

Like I say, we have heard this type of complaint before on the 10hp models. We found that there is a little bleed hole in the powerhead to spray a bit of cooling water directly in the top of the exhaust housing to keep it cool…Perhaps the fleetwin models have a similar bleed hole. I will have to look at a powerhead when I get home…May 25, 2018 at 11:08 pm #76731Thank you much. I would love to know the location of this bleed hole, so I can see if it’s clogged.

I have the 3M 847 so I will use that when I reseal, and I’ll put it only on the bottom of the impeller plate.

Have a great Memorial Day weekend!

May 25, 2018 at 11:17 pm #76732Tony, I totally agree with Fleetwin regarding checking under your power head for clogged water bleed holes. He figured this out for my 10HP, and by cleaning out the passage it fixed my hot exhaust housing. It was full of carbon / sludge from the poor oils used in the 50’s. The hole was so clogged I had to dig around with a pick before I could even find it. Note however it was a 10HP not a 7.5, so yours may be different, but definitely worth a poke around.

In addition another overlooked part to check for strong water cooling is #90 (302497) in the attached picture. The upper water tube grommet. It’s a bit hard to find and check since it’s located way up in the exhaust housing.

Post some pics when you get your head off. Good luck.

Bob DMay 25, 2018 at 11:32 pm #76733Mumbles, on the contrary, I have seen quite a few of those water tube restrictors down here in Florida. Maybe you Canadians drag them down here? Here in the swamp, they get obstructed with little chunks of decaying vegetation matter that will fit through the side bypass plate. I drill them out when I find them.

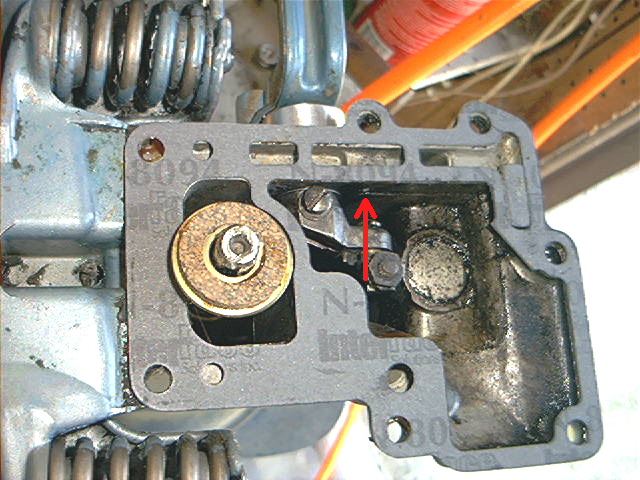

Sorry, I don’t have a picture of the 1957, but here is the location of the spray hole on a 1955.

May 25, 2018 at 11:35 pm #76734Yeah, Yeah, I know. That is the wrong powerhead gasket in the above picture. It shows how the "wrong" one can be modified to fit.

-

AuthorPosts

- You must be logged in to reply to this topic.