Home › Forum › Ask A Member › 1957 Johnson 10hp and 18hp gears

- This topic has 20 replies, 9 voices, and was last updated 5 years, 9 months ago by

Anonymous.

-

AuthorPosts

-

July 3, 2018 at 1:59 am #78928

Well, a little more digging did find something. Your pinion showed up in 1964 Evinrude edition of Quick Reference Guide. #304569 shows for Sportwin 10012-10013 motors #04719 & up – 10014-10015.

Shows gear set assy. #377147 for Sportwin 10012-10013 & Fastwin 15016 thru 15024.Still didn’t find your forward or reverse gear numbers, but one did supercede to the gear set? About all I got!

Dan in TN

July 3, 2018 at 2:35 am #78931Anonymous

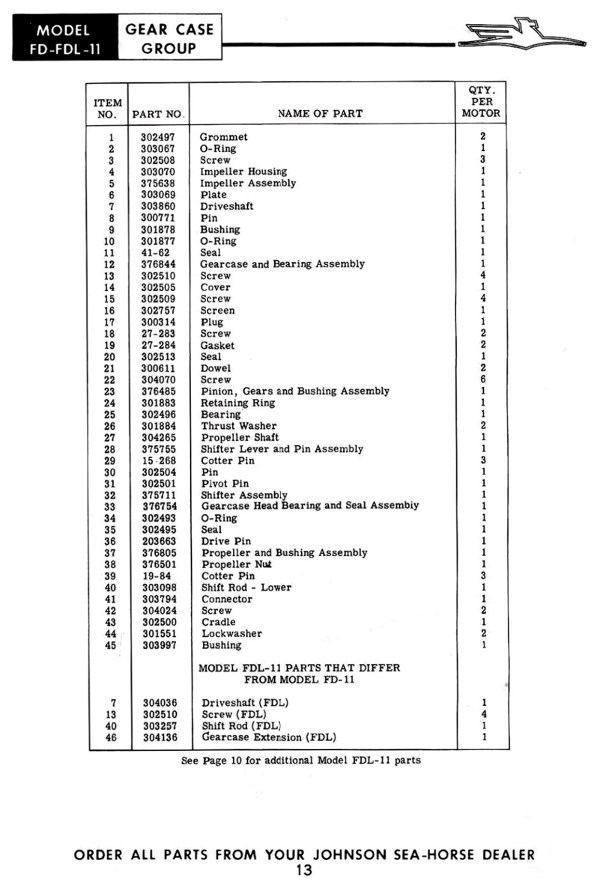

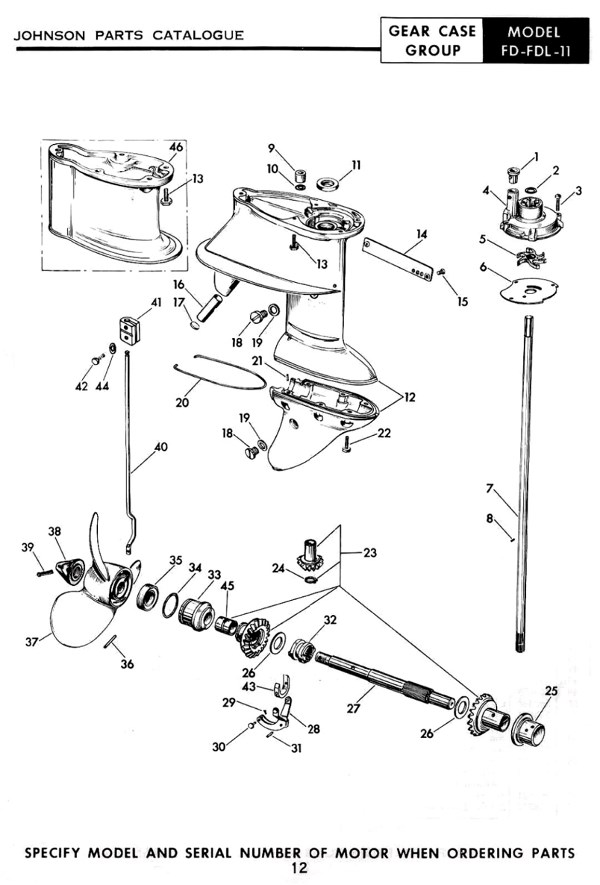

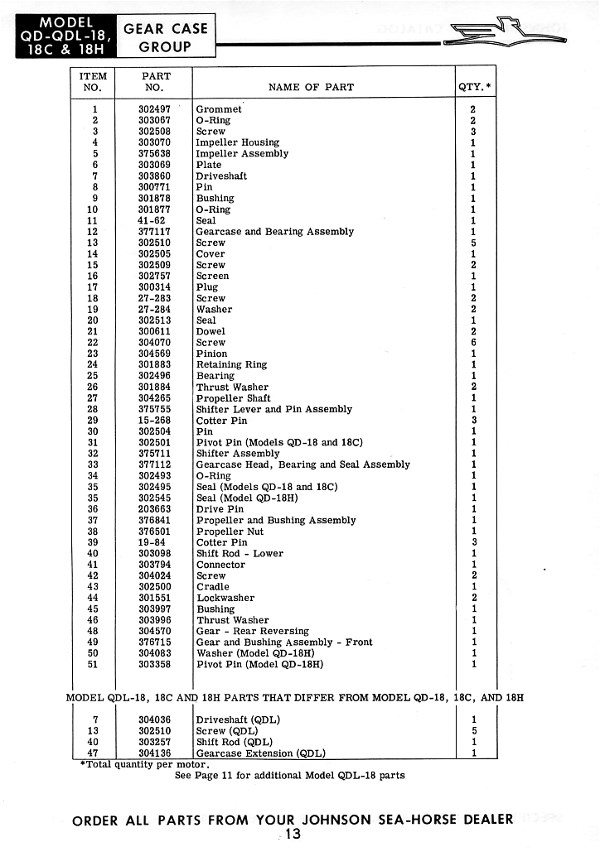

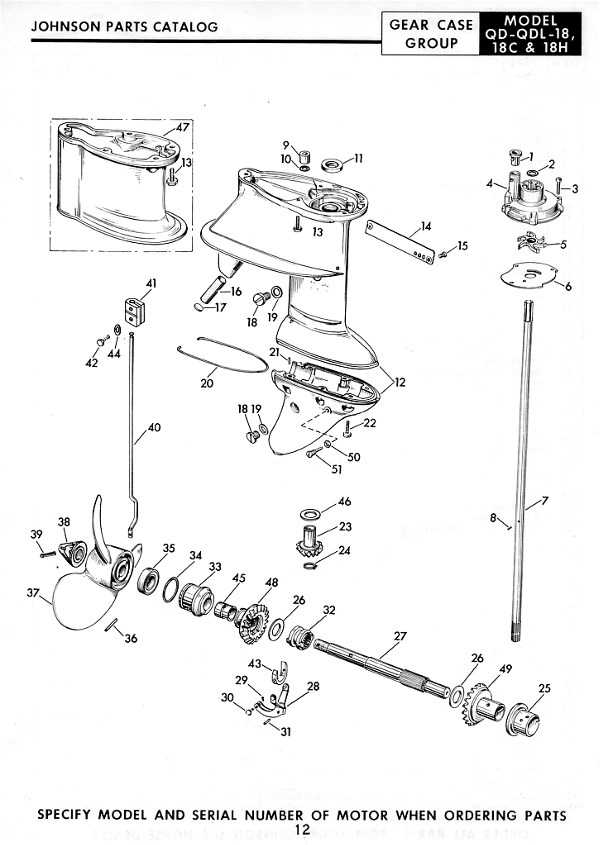

The numbers for a 1957 10hp are from a Johnson paper parts list for 1957 motor. A 1957 Johnson 18hp paper parts list only shows the gear set number.

July 3, 2018 at 10:55 am #78937July 9, 2018 at 3:35 pm #79271Anonymous

After looking at the parts lists and looking at several lower units, it seems that the 1952-1955 QD and the 1955 FD came with the same straighter cut spiral gears(pinion,forward,reverse). While the 1956-1957 QD and 1956-1957 FD came with more curved cut spiral gears(pinion,forward,reverse). The clutch dog seems to be the same in the above units. IMHO I think that each style could be interchanged as a set from 1952-1957.

July 9, 2018 at 8:20 pm #79283Finally figured out why I couldn’t do anything with the reverse gear #304570 number you gave. It ss to #305193. That gear (reverse) shows up in the Common Parts Guide. I am sure that might happen to the forward gear also if I had enough Parts Price books?

I do remember straight cut gears becoming spiral cut along in there somewhere? They were quieter, but not as strong. That may be why they got sold in sets?Dan in TN

July 9, 2018 at 10:59 pm #79291Anonymous

They sold in sets, because you can not mix the straighter cut with the more curved gear teeth. The gear teeth would not mesh.

July 10, 2018 at 9:55 am #79315Somewhere in the late fifties, don’t ask we where, exactly, they also changed the direction of the spiral cut from one way to the other. I have always wondered what the engineering reason was for that. If challenged on this, I think I MIGHT be able to find some examples in the basement…

Long live American manufacturing!

July 10, 2018 at 10:18 am #79318quote BillW:Somewhere in the late fifties, don’t ask we where, exactly, they also changed the direction of the spiral cut from one way to the other. I have always wondered what the engineering reason was for that. If challenged on this, I think I MIGHT be able to find some examples in the basement…Bill,

I believe you! My grandfather had a 1958 Johnson 18 that broke the driveshaft right at the pinion. His nephew was using it at the time and we never got the whole story. Anyway, I got a parts motor with the idea of just swapping the driveshaft, but the end of the shaft where it went into the pinion was different, as were the gears, so wound up swapping all the innards to make it work. Still running today!

July 12, 2018 at 7:29 am #79415XR55, You have an e-mail.

July 12, 2018 at 6:40 pm #79446Anonymous

Thank you Frank, I went into town today and stopped by the local E&J dealer to let them look at the prop shaft from the FD11 18hp outboard and new clutch dog that would not slide over the splines of the shaft. # 375711 dog, they had not had this problem but they said sometimes it went on snug. I next visited a machine shop and they thought the splines were the same. I picked up some permatex valve lapping compound. But first I had to run a file in the splines of the dog, about all that did was shine them up, but I could now at least get it started on the splines on the shaft. then I started the slow process of lapping the two parts together and after quite sometime I finally had the dog sliding freely on the shaft after washing out the compound. I also tried the dog on the shaft from a 1957 QD 10hp and it did not bind up. Great quality new OEM part.

-

AuthorPosts

- You must be logged in to reply to this topic.