Home › Forum › Ask A Member › 1963 Fastwin Upper Water Tube Grommet Replacement

- This topic has 12 replies, 8 voices, and was last updated 6 years, 7 months ago by

1946zephyr.

1946zephyr.

-

AuthorPosts

-

September 15, 2017 at 11:05 am #8231

Hi all. My first post with a question.

I’m working on a 1963 Evinrude Fastwin (18 HP) and would like to replace the upper water tube rubber grommet. It’s OMC part 302497. It’s the same grommet that goes on the water pump housing but this one is up inside the exhaust tube. The housing is too small to get your hand up in there and there are two small tabs on the grommet which I’m guessing need to align with two holes in the housing. I’m thinking I need to fashion a stepped tool to push the grommet into place butI cant see the holes to align them before I push it in and it seems difficult to rotate it once it’s pushed into place.

Any tips or tricks on how to complete this task would be appreciated.

Thanks.

September 15, 2017 at 11:36 am #64913Hey Lew,

Welcome and keep posting. Good question. What I do is take a piece of 5/16 threaded rod and thread a nut on a bit to push the grommet up in there with. It is easier than you think to get it right. Put a little grease on the grommet and it will slide right in. Easy enough to get it out and try again if it doesn’t line up.

Others will chime in on their own favorite methods.

September 15, 2017 at 12:26 pm #64915I would think the bigger problem would be getting

the "old" hard grommet out. What’s the best

method for that?Prepare to be boarded!

September 15, 2017 at 1:40 pm #64922The answer to both questions is "screwdriver". OMC makes a special tool to insert the grommet, but the tool is next to worthless. I use two big screwdrivers to poke and prod it in. The rod & nut sounds good too. Gotta try that next time.

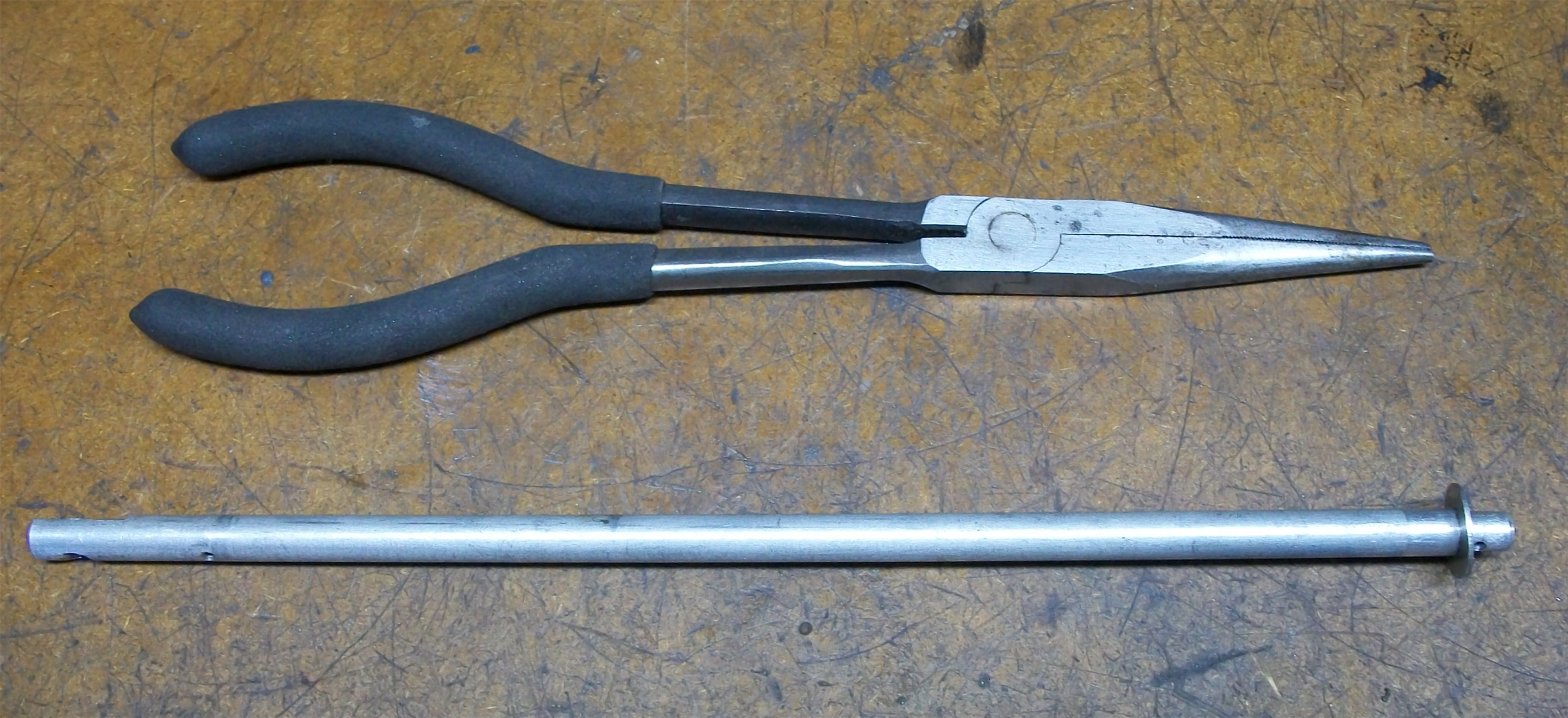

September 15, 2017 at 3:24 pm #64928I use long needle nose to get the old one out, Harbor Freight-about $4, comes in handy for a lot of other things too. I use this stepped rod with a washer to get them in. It’s actually an old throttle shaft. Grease the grommet as mentioned to make them slide in easier. Once you start to see part of the tab from the outside of the housing you can get the tip of a small screwdriver on it to help coax it into place.

September 15, 2017 at 7:38 pm #64943I use a stepped tool similar to Steves.

As mentioned, grease her up good!

You will notice a hole on the outside of the leg of the lower unit that you stick a punch into to depress the tab to both remove/install the grommet.

September 15, 2017 at 9:54 pm #64948Wow – thanks everyone. All great advice.

I tried the 5/16 threaded rod with the nut but what I’m running into is the grommet just bulges out when I press on it and it doesn’t want to seat in to the hole. I actually fashioned an even better tool with a craftsman 3/8" socket extension with 3/8" to 1/4" adapter at the end that was the perfect size. I wrapped electrical tape around the 1/4" nub to make a longer and thicker inner shaft.

What I’m sensing is the shift rod and the lower connector (OMC 303794) seem to be in the way for me to be able to get any action from the side and that seems to be the only way I can coax it into place its to access it through the hole in the side. I can see removing the shift connector and moving the upper shift rod so it’s in the up position to give me better access to the side where the grommet is. If that doesn’t work it seems my next step would be to remove the power head – ugh. Didn’t really want to go there but will do so if needed.

Off camping with the boy scouts this weekend but will be back at tying to get this piece back into place on Sunday.

September 15, 2017 at 10:35 pm #64950Your problem is that the 5/16 rod wont allow the "tabs" to depress, allowing the grommet to fit into the hole, until they can expand back out once seated. I milled out areas on either side of my tool, allowing the area around the tabs to depress just for this reason.

September 15, 2017 at 10:47 pm #64952September 16, 2017 at 12:03 am #64955It looks a lot like the factory tool . . . 😀

-

AuthorPosts

- You must be logged in to reply to this topic.