Home › Forum › Ask A Member › 9.9/15 Seal Orientation

- This topic has 9 replies, 6 voices, and was last updated 6 years ago by

fleetwin.

-

AuthorPosts

-

April 15, 2018 at 7:53 pm #9651

In another post I said I thought the lower crank and driveshaft seals were installed with the lips facing away from each other but now I’m not so sure about that and here’s why.

I dug out two fresh powerheads with different style seal holders on them and found two more in my stash. The motor with double seals has them installed with the lips in, facing each other while the single seal carrier off the other motor has the seals lip facing the motor, as is normally done. The two loose ones look as if they have had new seals installed and they both have the seals installed the same way as the ones on the powerheads. The seals would have been replaced as soon as the old ones were removed to avoid confusion so I’m thinking they gotta be right. But then…… 😕

April 15, 2018 at 9:00 pm #74069I would think by facing each other, there would always be a tittle oil between them. That should help keep the water out. . . 😎

April 16, 2018 at 12:10 am #74089

April 16, 2018 at 12:10 am #74089…and the splines lubed…

Just got off ebay…there is one of each style there…the 2 seal one has both seals facing each other but the older 1 seal style has the seal facing away from the motor…must have been replaced facing the wrong way..

https://www.ebay.com/itm/SMA7089-BRP-JO … UB&vxp=mtr

https://www.ebay.com/itm/82-Johnson-Evi … e3&vxp=mtr

https://www.ebay.com/itm/9-9-15-hp-John … Mz&vxp=mtr

April 18, 2018 at 5:05 am #74229Well, this is an interesting topic…I was reading a manual describing the orientation of the two lip system on the 6-8hp, and it did not make sense to me. I’m pretty sure that on the single seal cover the seal lip faces up towards the powerhead. And, it would make sense that on the two lip system the seal lips face each other. In other words, the big crankcase seal lip would face down while the driveshaft seal lip faces up…I would think that you would want the small driveshaft seal lip facing up so that the driveshaft would not catch on the lip as you install the gearcase….

But, I don’t think this is what the OMC manual stated…I will have to look at it again when I get home in a few days….April 18, 2018 at 1:46 pm #74246found this among my pictures:

Although this seal is messed up, I know it came from the factory like this….

So, it looks like both seals in the two seal system are installed with the lips facing up, like it said in the manual…

Yes, this is from a 6hp, but am pretty sure it would be the same on the 9.9/15s, will look into the manuals some more when I get home…DApril 20, 2018 at 7:16 pm #74387Just reviewed a few manuals again….The 1990 6-8hp manual prescribes pressing both seals into the housing with the lips facing up toward the powerhead…

The 1992 and 1998 9.9-15hp manuals prescribe pressing the lower/small seal with its lip facing up, but prescribes pressing the larger seal into the housing with its lip facing down…So, the seal lips would face toward each other… I don’t have a mid 80s svc manual, so not sure what was prescribed during that period.

I certainly agree that the small seal should have its lip facing up toward the powerhead so the driveshaft will not catch on the lip during gearcase installation….And, I guess you could argue both ways for the larger seal, and it seems like OMC had a few different methods depending on engine family…April 20, 2018 at 7:46 pm #74388Pretty much every powerhead I’ve ever been into has has the lip facing the powerhead. The double seal applications above, the bottom seal acts as the o-ring did on the older style shafts, to keep the grease in the crank splines. So, facing the lip up would achieve that better than down, plus have the added benefit of being less vulnerable to damage during lower unit installation. OMC replace the o-ring with a seal on most, if not all, of their models by the late 1980s.

April 20, 2018 at 10:10 pm #74395Yes, most if not all of the single seal lower crankcase seal set ups I have seen have the lip facing up into the powerhead as well. But, having the two seals makes it a different game I guess…

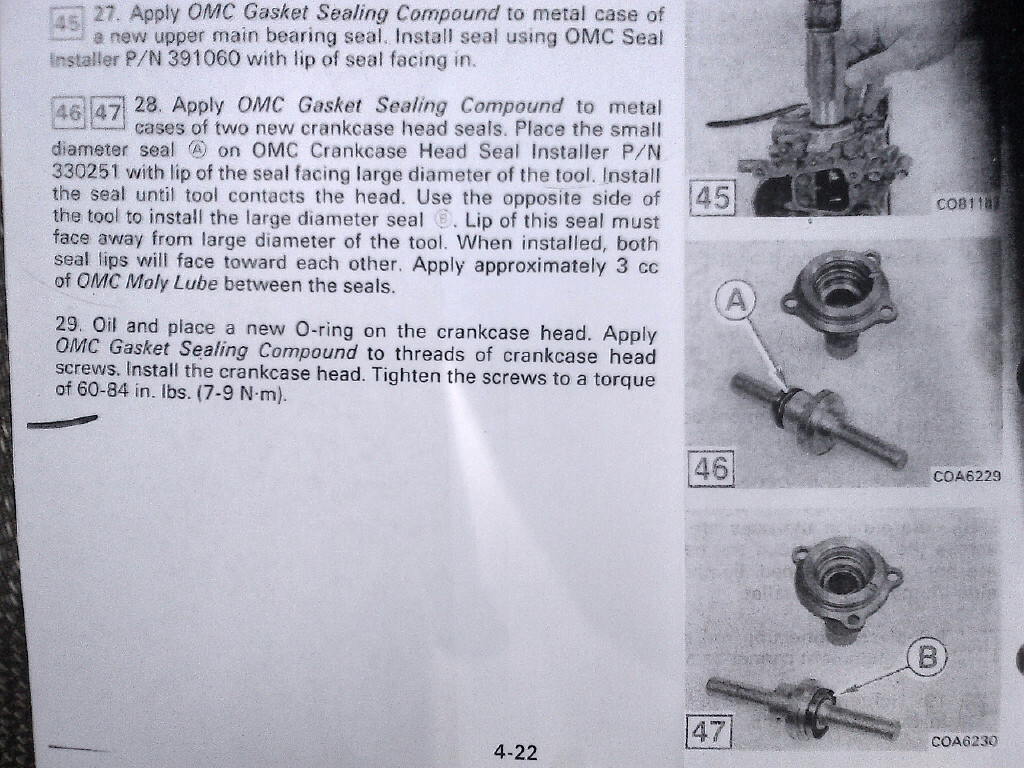

Some of the newer engines had an oring that was lodged in the crankshaft instead of the driveshaft as well, the 32CI engines were some of the first to use this set up. I always questioned this set up saying that you would never know if the oring was in place without removing the powerhead. But, I guess having the oring housed in the crank made it much less likely that it would become dislodged broken during gearcase installation/removal.April 24, 2018 at 7:02 am #74630Here is the info on Crankshaft head seal installation out of my J/E 1989 9.9-30 manual . With the seals facing each other,it serves as a little grease reservoir for the 3 cc of Triple Guard grease as recommended ,before lower unit installation

As i recall from my Metric System "research", a cc and a ml are the same amount. So 3 cc’s isn’t much grease to place in the space between the seals, more may prevent the driveshaft splines from seating fully.

This newer 2 seal design seems like an improvement over the earlier single seal and driveshaft O Ring design."Some people want to know how a watch works, others just want to know what time it is"

Robbie RobertsonApril 24, 2018 at 12:31 pm #74639OK, seems to be the same instructions as the later models. Although they could have made the instructions a little less confusing, perhaps added a diagram…But, looks like the seal lips face in towards each other on these engines. And yes, this set up seems as though it should have helped with seized driveshaft splines, but problems still continued on the 6-8hp models. The beauty of the 6-8hp models is that the gearcase pops on and off so easily (no shift rod connector), no excuse not to pull that gearcase down every year (for salt water users) to clean and relube the splines…

In the example of that 1985 6hp seal I pictured, that powerhead must have been one of the first assembled in the Calhoun plant, it was a disaster. Looks like the crankcase seal lip was damaged during installation on the line, the gearcase had never been off before. But, in this case, the lower driveshaft seal acted like the lower crankcase seal and saved the powerhead from water damage….

Thanks for posting the instructions! -

AuthorPosts

- You must be logged in to reply to this topic.