Home › Forum › Ask A Member › FD-16 Install

- This topic has 6 replies, 4 voices, and was last updated 6 years ago by

skanders01.

-

AuthorPosts

-

April 25, 2018 at 11:23 am #9737

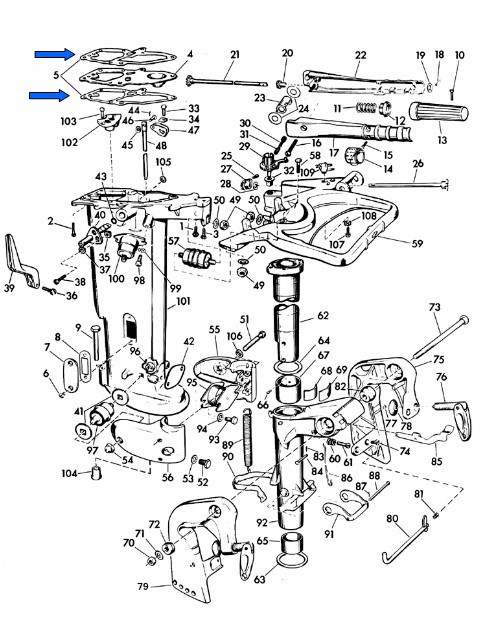

Now all painted up, it is time to introduce my FD (16 & 19) powerheads to the lower half of their respective motors. Interface assembly has two fiber gaskets with a thin steel baffle sandwiched in between them. Should I use gasket sealants on all 4 gasket sides? Or maybe all (3) but the gasket face that adjoins the powerhead to facilitate removal if I need to? No sealant?

None of my reference books address sealant for the gaskets involved with this assembly.

Thanks for any advice!

Kyle Anderson

Trempeleau, WI

skanders@triwest.net

920-764-0501April 25, 2018 at 4:18 pm #74744I don’t generally use sealants on those if they’re new gaskets. I do coat them with grease, though.

April 25, 2018 at 5:45 pm #74748Kinda depends on which gaskets you have? Are they the old NOS original asbestos hard gaskets? If so I would put OMC gasket sealing compound (NAPA Aviation sealant) on them. It’s non hardening & will allow removal for the near future. Grease could be used on them to soften them & make them reusable?

If you are using the newest style gasket that have the shiny/sticky substance on them then no sealant is required. These gaskets are a lot thinner and retain torque much better without sealant or grease. They will stick after heat up! I would not grease them & sealer is not needed.Dan in TN

April 25, 2018 at 9:12 pm #74768April 25, 2018 at 11:50 pm #74777I was referring to those same gaskets. The latest gasket #314421 has a cellophane wrapping inside the plastic pack so it doesn’t stick to the packaging. Those gaskets don’t require any sealant. See enclosed photo.

If you look close you can see the shiny surface and the cellophane stuck to the gasket. These gaskets are much thinner than the original gaskets. Thinner gaskets when stacked (baffle in between) stay tight better than thick gaskets. It’s better if they don’t have adhesive or grease so things don’t move. I understand the desire to save gaskets & avoid clean up if it has to be removed again, but that is the way it is suppose to be with the new style gaskets. I still have a bunch of NOS gaskets myself. I like the new style, but not the price for one time use.

Dan in TN

April 26, 2018 at 1:04 am #74794Good info Dan. I misread/misunderstood your previous post. I have used grease on them in the past just to save them if possible if I had to remove the powerhead again but I see your point in the PM you sent. Thanks.

April 27, 2018 at 12:51 pm #74859Thanks very much for the information, gentlemen. The gaskets were just paper type gaskets I made; steel baffle was a great pattern for most of the cuts/bolt holes. They are indeed the gaskets identified. I lightly greased the first set and left the second motor’s set uncoated. My glass will be at least half full one way or another.

Hope you are doing well, Dan.

Kyle Anderson

Trempeleau, WI

skanders@triwest.net

920-764-0501 -

AuthorPosts

- You must be logged in to reply to this topic.