Home › Forum › Ask A Member › Johnson Evinrude 9.9/15 lower unit interchange

- This topic has 15 replies, 5 voices, and was last updated 6 years ago by

Mumbles.

Mumbles.

-

AuthorPosts

-

April 13, 2018 at 7:28 am #9629

I have acquired 3 spare lower units for the 9.9/15’s. What years lower units will fit my 1976 -89 motors? I have a 1976 9.9,’89 9.9 and a ’89 15 hp (so far). The lower units i have all look the same. Will the casting number on the inside near the top of one of the recesses tell me anything?

Thanks, Jim PSB"Some people want to know how a watch works, others just want to know what time it is"

Robbie RobertsonApril 13, 2018 at 11:54 am #73911Jim

The difference is usually only the upper driveshaft splines…74-84 models use the grooved splines/oring, 85-92 models use the driveshaft with no oring for the splines…

The 93 and newer models are a bit different than the earlier models….

Casting numbers on the gearcases will be no help in trying to identify these things, you need to be able to look at the driveshaft identify. Keep in mind, the driveshafts are easily swapped on these units, they just pull out….April 13, 2018 at 9:38 pm #73937Fleetwin-Thanks for the info. I will make a note of it in my manuals. Leeroy’s ramblings has a lot of info on this series too, looks like he has added some info within the last few months. It is informative and fun to read, the photos help show what he is describing.

Thanks ,Jim PSB"Some people want to know how a watch works, others just want to know what time it is"

Robbie RobertsonApril 13, 2018 at 11:14 pm #73939..just to add to what fleetwin said…there are 2 styles of lower seal head thingys…the older single seal style is for the oring drive shaft. The newer ones have 2 seals in them and do not use the oring…ya can use the older oring style shaft with the newer 2 seal…just do not use the oring. The newer 2 seal style have a step cast in to them to hold the 2nd seal. They are easily identifiable by the lump near the flange.

April 13, 2018 at 11:27 pm #73941quote rudderless:..just to add to what fleetwin said…there are 2 styles of lower seal head thingys…the older single seal style is for the oring drive shaft. The newer ones have 2 seals in them and do not use the oring…ya can use the older oring style shaft with the newer 2 seal…just do not use the oring. The newer 2 seal style have a step cast in to them to hold the 2nd seal. They are easily identifiable by the lump near the flange.Well, I’m not sure I would use the grooved driveshaft with the two seal crankcase head, even though everything will surely fit together. I worry that the oring groove would catch on the lower seal and damage it…..Don’t know this for sure, but I would not take the chance….

April 14, 2018 at 12:54 am #73946The instructions that came with my omc seal kit explained this. I checked it out myself before assembly. The 2 seal one is a better design.

April 14, 2018 at 10:38 am #73960Would love to see the instructions. The two seal head has its advanatages, and can be used on older powerheads if you swap the driveshaft as well. But, I don’t think the two styles should be mixed…

April 14, 2018 at 4:36 pm #73969I had bought a powerhead gasket kit from somewhere…4years ago…for my 76 and the distructions explained this. I also slid the newer seal head over the shaft before assy to be sure I was reading them correctly. The oring groove did not catch the seal…it slid right over it just fine.

…I wouldn’t s4it ya…you are too big a turd! 😉

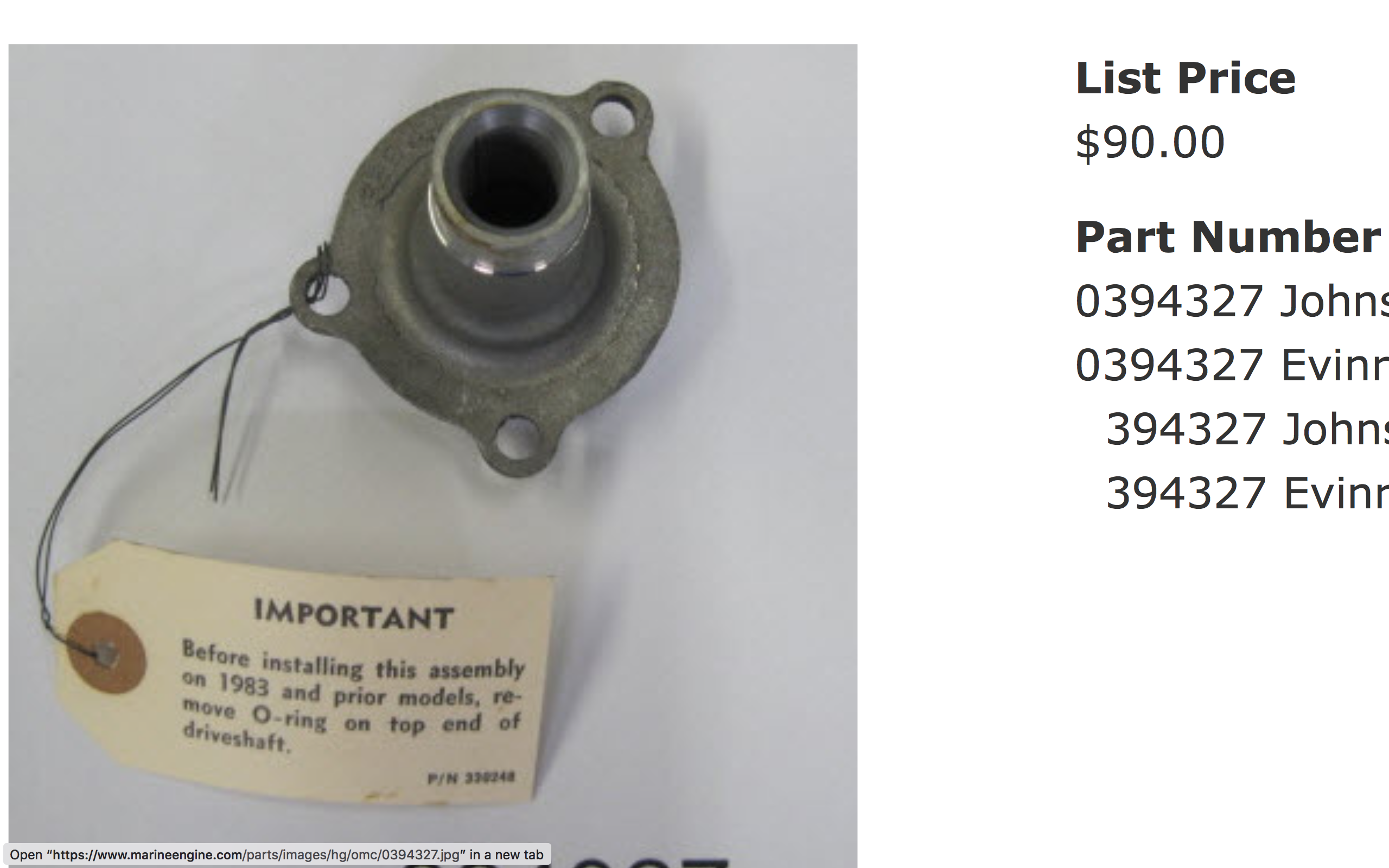

April 14, 2018 at 4:47 pm #73970Looks like BRP may have just obsoleted the earlier design (ME still has some) & moved on to just the one style. Anything to simplify parts availability. They don’t seem to care if it works properly or not! I’m with Don. I would at least try to smooth the sharp edges of the o-ring groove on the older style drive shaft. I would also still put Moly lube on the spline. That will help it get past the groove without damage to the seals. If you look at the new #394327 it has a tag tied to it referencing it to later uses. Hope that helps.

Dan in TN

April 14, 2018 at 6:03 pm #73981 -

AuthorPosts

- You must be logged in to reply to this topic.