Home › Forum › Ask A Member › Johnson PO38

- This topic has 9 replies, 5 voices, and was last updated 5 years, 8 months ago by

The Boat House.

The Boat House.

-

AuthorPosts

-

August 15, 2018 at 1:50 am #10855

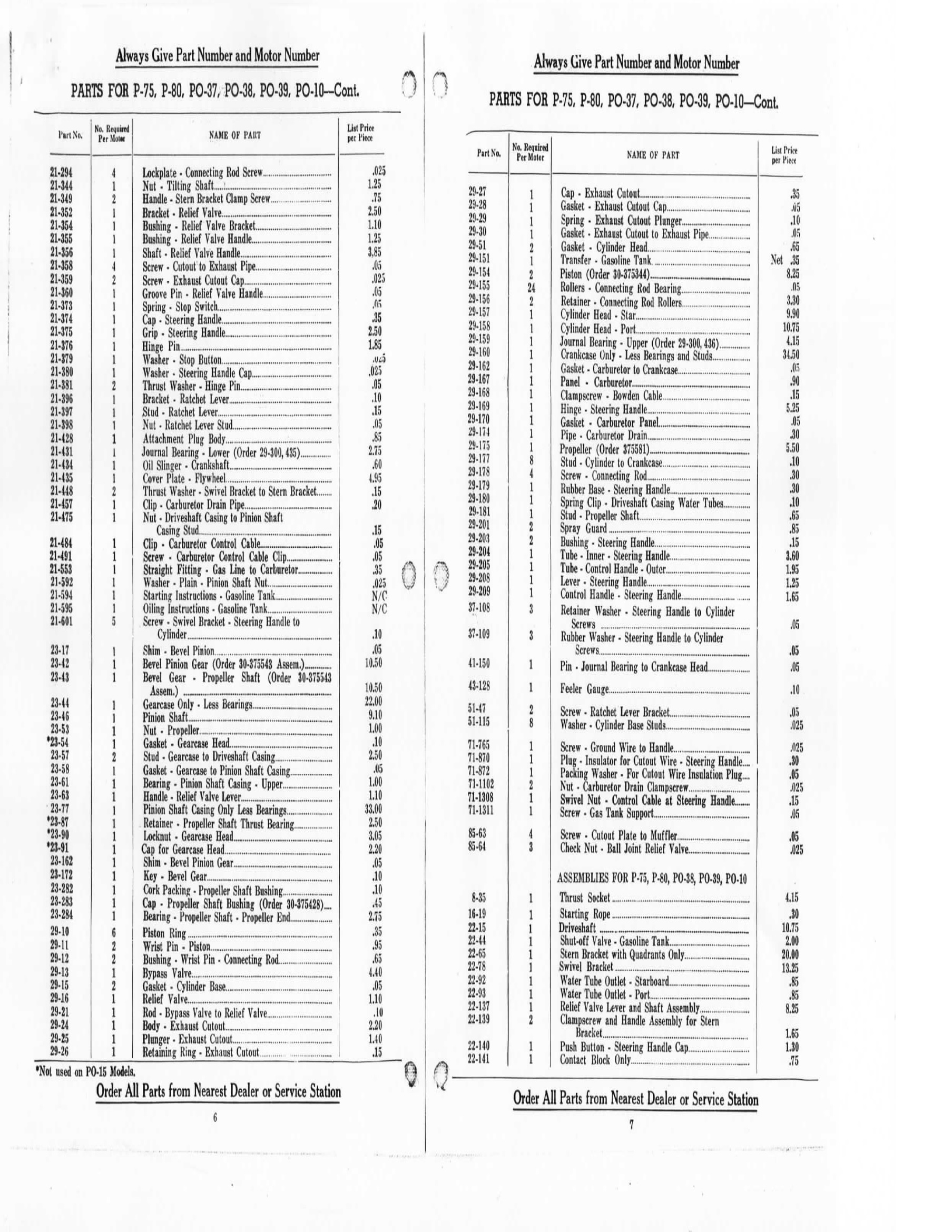

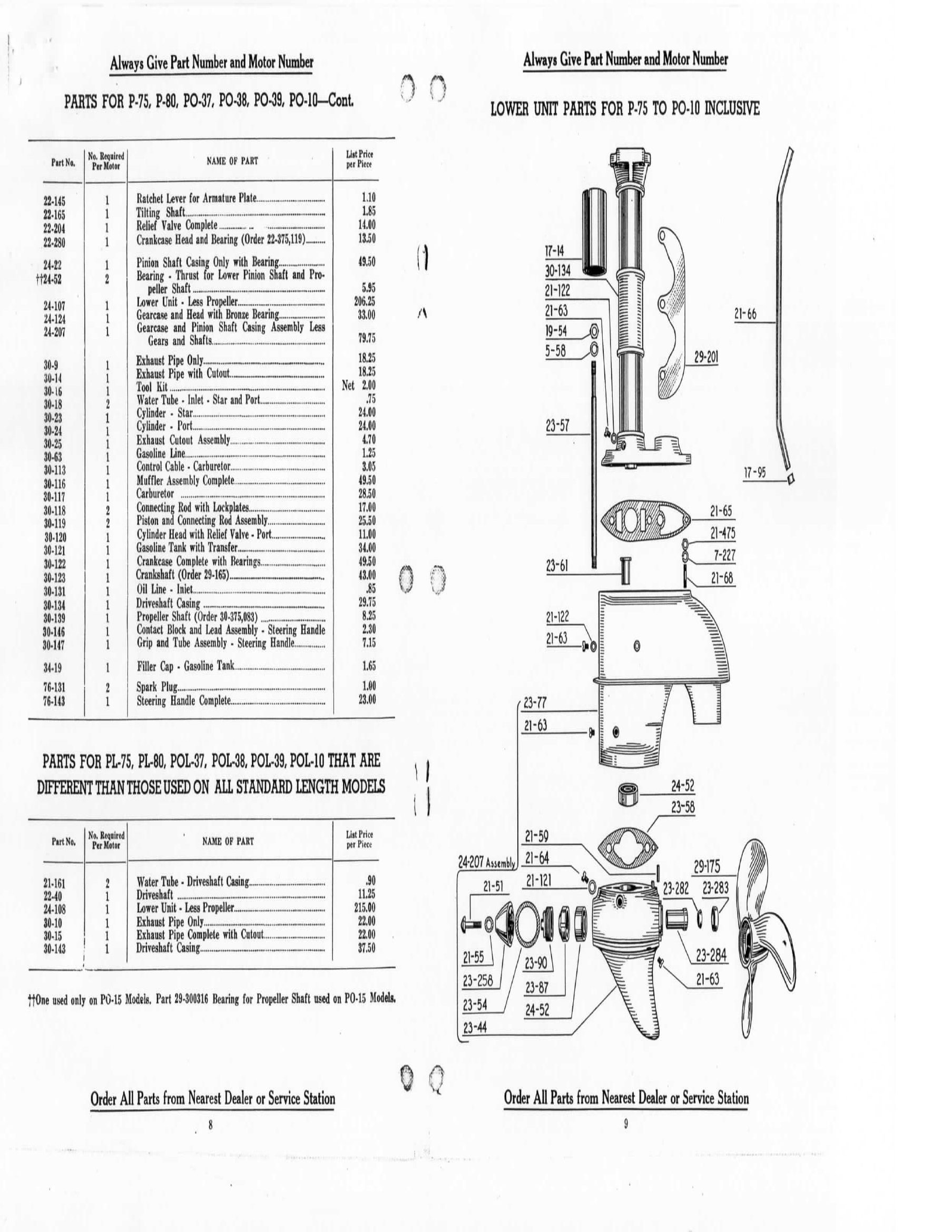

Hello everybody. I bought a 1938 Johnson PO38 for $50 a couple days ago. It is in decent shape and the past few hours in the shop I spent getting some things working. New plug wires, new plugs, cleaned and lapped the decompression valve, etc. It has real good compression now. I have a few questions about it.

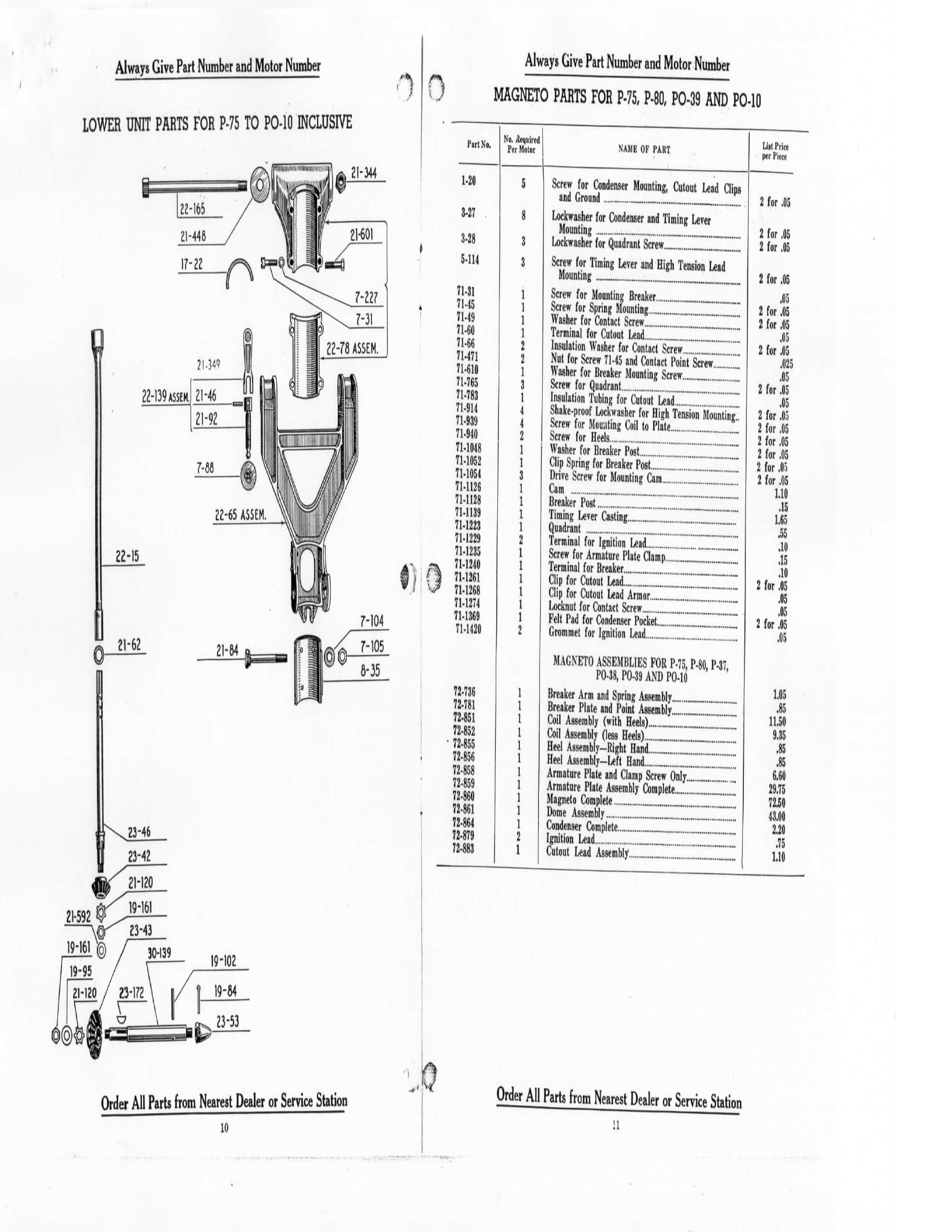

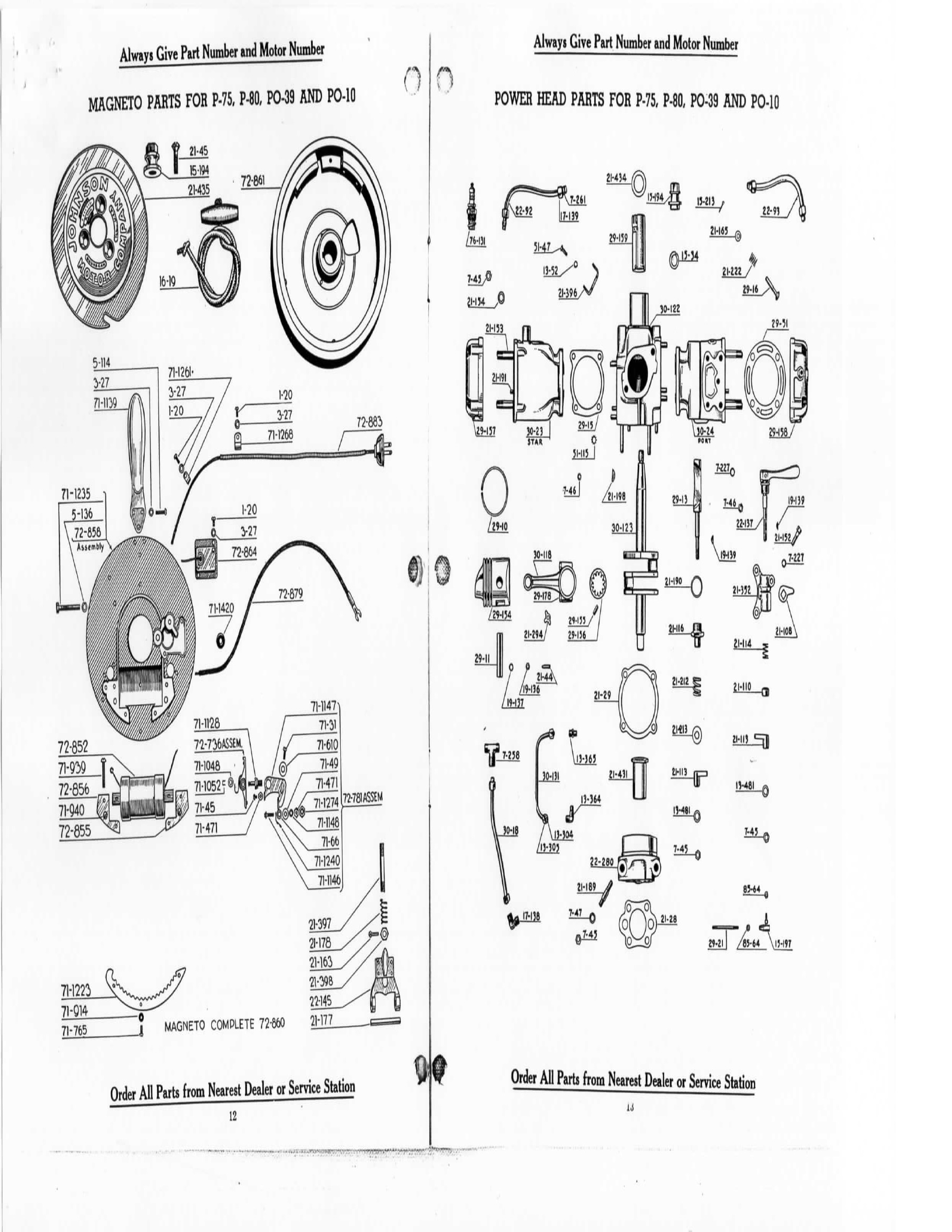

The screws that hold the flywheel cover on are stuck good. I have tried impact, heat, oil, and cursing. Nothing has gotten them out and I can’t set my points until I do. Anybody got tricks? I am not opposed to drilling them out as long as I can find replacements but no luck on that so far. If anybody knows where to get them I would appreciate it.

How were these painted originally? I have seen PO15s in light green but mine is painted silver.

Anybody got any leads on a condenser? Right now I have an extra from my ‘48 Jeep rigged up. Still no spark but I still haven’t set my points either so who knows.

Thanks folks. I’m in Oklahoma and none of the local boat shops want to even try to help me with this so I’m kind of dead in the water. Pun intended.

-ZacAugust 15, 2018 at 3:52 am #81181Mr. Harris, first of all, I would like to welcome to AOMCI. You have found the right place to help you restore your old motor and get it running well. There are several guys familiar with your motor and can help you along the way.

Couple of thoughts and suggestions:

1.) Please don’t be in too much of a rush to get your motor going. Believe me, we have all been there and made mistakes due to the excitement. Please take your time evaluating the motor and replace parts only if necessary.

—– Please be patient with the name plate / rope sheeve screws. Penetrating oil and the manual hand held impact wrench is the way to go. Be very careful with the heat or you will end up destroying your coil. The coils on the those old Johnson motors are usually still good. If not, there can be found used replacement with in the club. There are members who have posted excellent youtube videos how to repair them with coil bodies of modern coils.

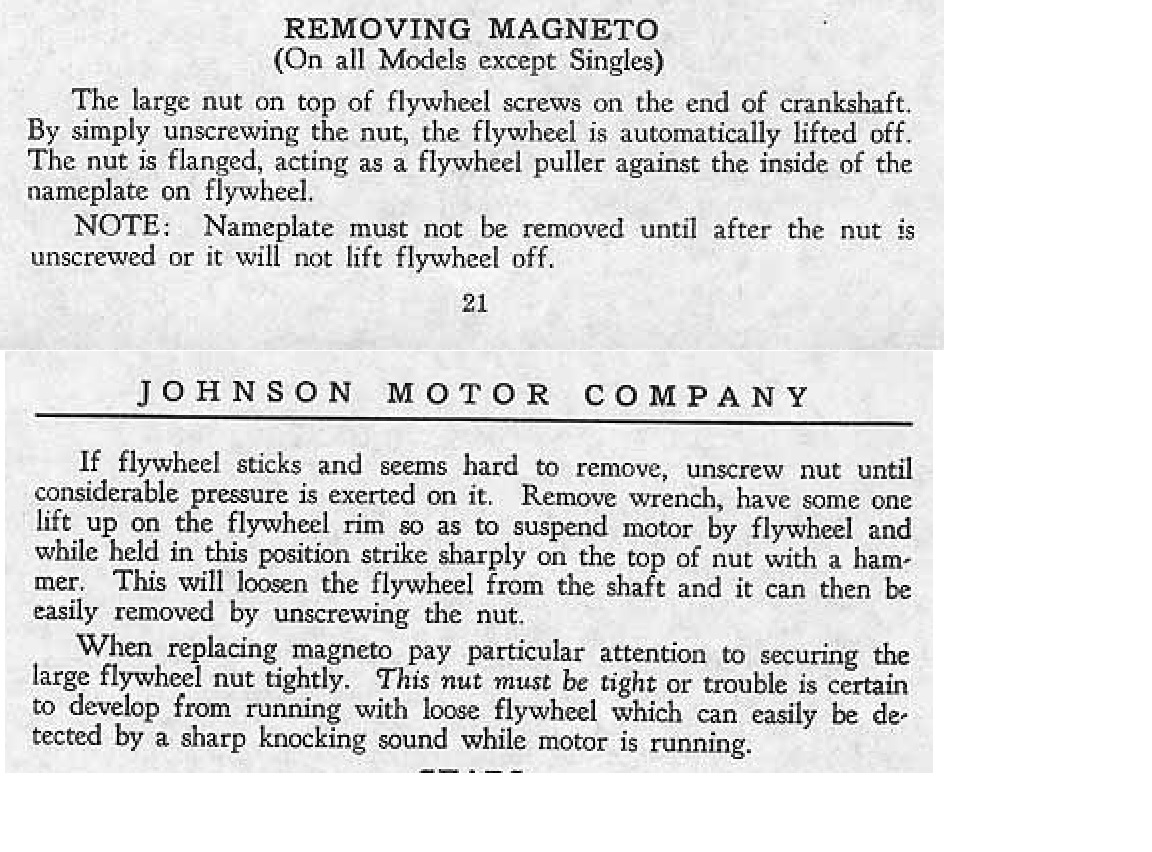

I will post a snap shot of the instructions for removing the flywheel.

2.) Your motor original color is dull aluminum to silver coloration. Except for the decals on the tank.

3.) The plug wires will be will 7mm to 9mm or better copper core wires and not the auto wires of today.4.) If you PM (private message me with your email address), I can send you some very help information for your motor.

If you like restoring old motors, please consider joining our club. There are local chapters in Texas and Louisiana. As always the site here is free. We, the club members, support the online free portion and enjoy helping people bringing old motors back to glory!!!

August 15, 2018 at 3:52 am #81182August 15, 2018 at 4:14 pm #81210Thank you very much. I have had the flywheel off while heating it up for that very reason. A manual impact is about the only thing I haven’t tried. I have one, but the biggest bit I have is a 3/8” and these screws are 3/4 across. Think that would tear it up? I already put a 3/8” slotted bit in my pneumatic impact and it just broke the bit right off.

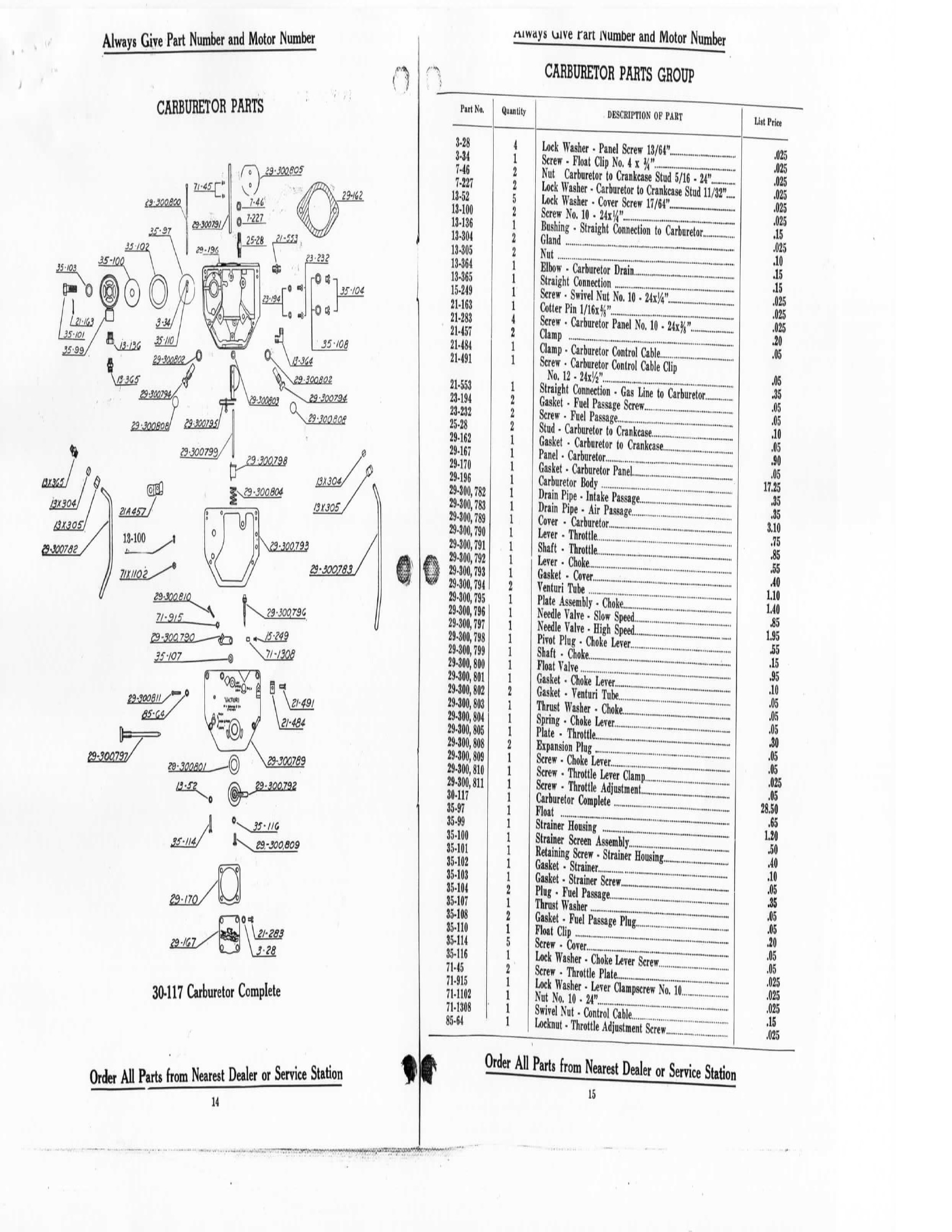

I already have that parts manual and I did use the old school cotton plug wires. This ain’t my first rodeo, haha. When working on such an old machine a manual is usually my first move.I will try to find or make a 3/4” slotted bit for my impact. If not, are the screws available?

August 15, 2018 at 4:22 pm #81211Oh and my coil is good I think. Multimeter across the plug wires shows 9k ohms, is that good?

August 15, 2018 at 5:16 pm #81212I use a drag link socket on big screws.

August 15, 2018 at 5:58 pm #812139k ohms across the secondary is a good coil.

August 15, 2018 at 6:26 pm #81214quote Mr Harris:Thank you very much. I have had the flywheel off while heating it up for that very reason. A manual impact is about the only thing I haven’t tried. I have one, but the biggest bit I have is a 3/8” and these screws are 3/4 across. Think that would tear it up? I already put a 3/8” slotted bit in my pneumatic impact and it just broke the bit right off.

I already have that parts manual and I did use the old school cotton plug wires. This ain’t my first rodeo, haha. When working on such an old machine a manual is usually my first move.I will try to find or make a 3/4” slotted bit for my impact. If not, are the screws available?

Well, you having some experience working with these old motors, does help…..lol

Screws can be obtained from parts motors or someone in the club may have an inventory of some to sell to you.

I have not worked on Johnson PO motor, but do I have these models

1937 Johnson model 110 1.7hp

1937 Johnson model KA-37 9.2hp

1940 Johnson model HA-10 5hp

1948 Johnson model KD-15 9.7hpThe usual resistance is between 3 to 7 ohms, but on your coil and ignition I am uncertain. One of the other guys may offer guidance.

Another thing to consider, is your magnet. Pre WWII magnets were soft magnets that would require re-magnetizing. Post WWII are permanent magnets and require no maintenance. My Johnson KA-37 barely put out spark, but one of AOMCI members re-magnetized the flywheel magnets and I was getting big fat blue sparks jumping about 3/8 inch with a open air gap spark checker.

There are used condensers that are still good and can be obtained from members, but in the past several years the use of modern solid state condensers have served well with some of these old motors. I put one on the Johnson KA-37 and I have good spark. I am looking for the type and range of that condenser. If I can find it I will post it. Maybe someone who has the information on hand can post it.

Please post pictures or vids of your motor project. We always love a good project and pictures. Oh, I have sent the information to your email address under http://www.wetransfer.com.

Cheers,

Cajun

August 15, 2018 at 6:48 pm #81217

Ah, I have found my notes of the type solid state capacitor I used in the 1937 KA-37 for condenser replacement.I substituted the condensers with 22mF 640V capacitors

I can’t remember the name brand or where I purchased them. Someone will definitely have an answer for you.

Cheers,

Cajun

August 17, 2018 at 2:38 am #81350-

This reply was modified 5 years, 5 months ago by

The Boat House.

-

This reply was modified 3 years, 2 months ago by

The Boat House.

The Boat House.

-

This reply was modified 5 years, 5 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.