Home › Forum › Ask A Member › Johnson TD20 / TN26 etc. – T-shooting Part 2

- This topic has 24 replies, 6 voices, and was last updated 9 years ago by

garry-in-michigan.

garry-in-michigan.

-

AuthorPosts

-

April 29, 2015 at 5:17 am #14977quote ShoestringMariner:You might be on to something here…as the impeller tube terminates at the base of the powerhead…could be flowing water in the exhaust, though would it not be pushed back out by compression/airflow?

You’d think, but then again.. I can’t just dismiss anything at this point, as the dang thing runs for crap and nothing seems to help it.

quote :What about a cracked block? I’d think a crack would get larger as the block heats up, would it not?This is a real possibility. Prior to the POs messing with it, the motor was left sitting for many years, and one needs to ask just why that was.. It may have simply been un-needed, but then again, it may have been seriously screwed up and set aside to be fixed at some later date. Maybe the poor thing froze with a full water jacket or some such awfulness?

Thing is, I had it totally apart, and didn’t see anything that looked like a crack in the cases.

Anyway, it’s all apart again, except for splitting the cases. Careful inspection is next..

One obnoxious thing, though. When I pulled it apart, the +new+ carb flange gasket was torn, badly. So did that happen during disassembly, or..?

Ack. A grand worth of time into a $150 motor! =P

April 29, 2015 at 12:12 pm #14986On the TD-20, the exhaust enters the midsection below the base gasket. The exhaust has its own gasket, the rectangular vertically mounted one you can see that joins the powerhead to the midsection.

Underneath the base gasket, in the midsection, the exhaust mixes with the cooling water that is exiting from the external cooling tube that connects to the cylinder head.

The only way that I can think of that water would be backing up into the exhaust would be if the midsection was clogged up with carbon and oil and unable to drain. If that was the case, then the motor probably wouldn’t run at all.

April 29, 2015 at 11:32 pm #15043quote aquasonic:On the TD-20, the exhaust enters the midsection below the base gasket. The exhaust has its own gasket, the rectangular vertically mounted one you can see that joins the powerhead to the midsection.Underneath the base gasket, in the midsection, the exhaust mixes with the cooling water that is exiting from the external cooling tube that connects to the cylinder head.

The only way that I can think of that water would be backing up into the exhaust would be if the midsection was clogged up with carbon and oil and unable to drain. If that was the case, then the motor probably wouldn’t run at all.

Could the spring and washer at the stem be stuck partially closed, or not allowed to open well, causing expelled cooling water to pool?

April 30, 2015 at 4:41 am #15086quote ShoestringMariner:Could the spring and washer at the stem be stuck partially closed, or not allowed to open well, causing expelled cooling water to pool?Sorry – which spring & washer at which stem?

FYI – the complete magneto & carb which were being used on the ‘trouble’ motor are back on the ‘good’ motor – and it’s running super! So the source of trouble isn’t in the carb / mag – period, full-stop!

This is down to gasketing / sealing etc. on the bogie motor, or something else fundamental.

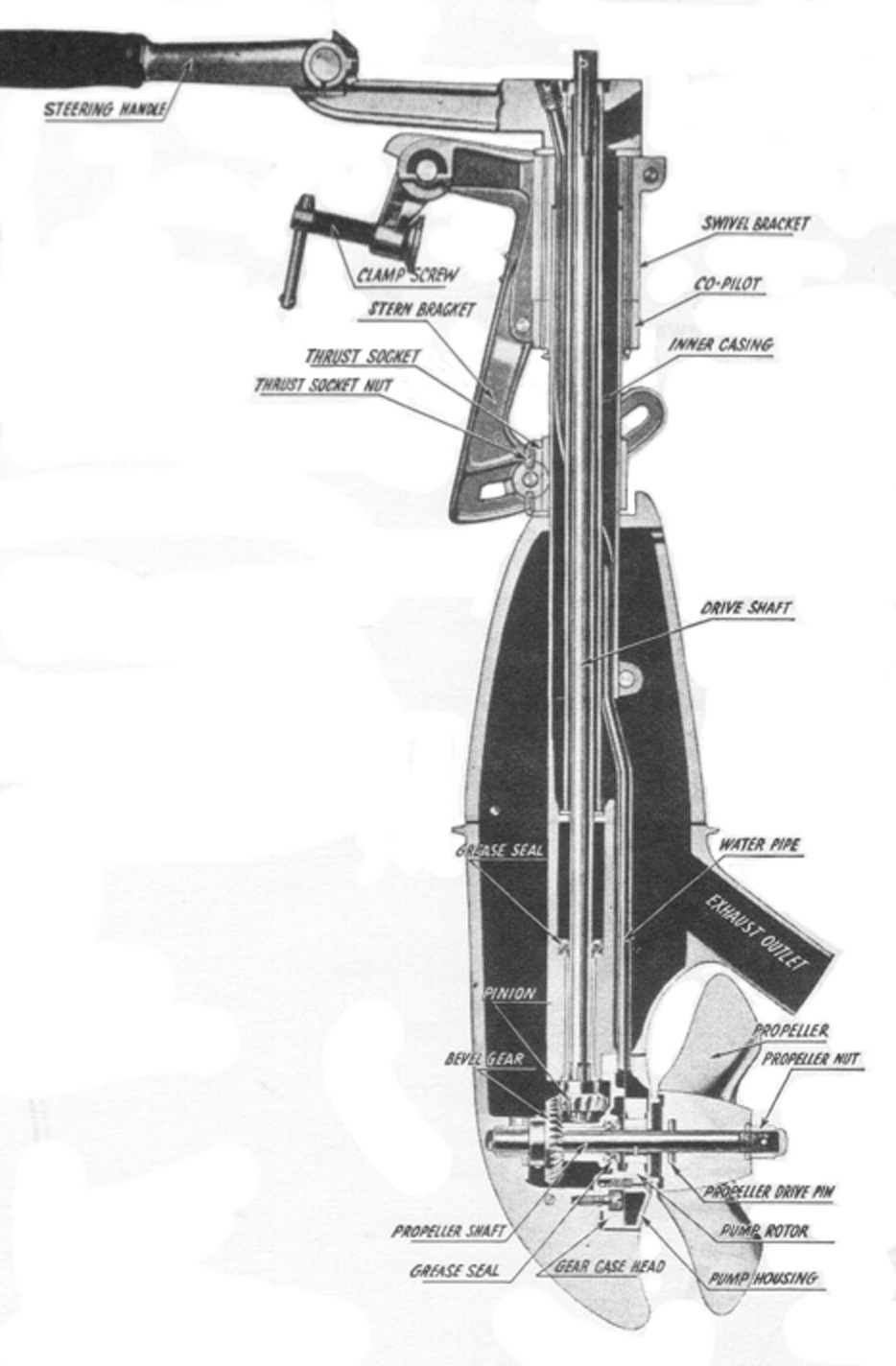

April 30, 2015 at 4:07 pm #15105Is this any Help? A few JW/Lightwins were found to have a bent water line which rubbed on the drive shaft. This wore a hole in the water line which then leaked water into the exhaust cavity.

. . . . . ❓

April 30, 2015 at 7:39 pm #15123

April 30, 2015 at 7:39 pm #15123The TD20 drive shaft runs inside of a brass tube – so it can’t rub on the water line. Thanks for that graphic, though – where’d you get it?

May 1, 2015 at 2:45 am #15155Am I correct, in that these motors lack any sort of crank seals?

I mean, there aren’t any rubber / lip seals of any sort, and the motor relies on the fact that it’s a plain-bearing bottom end to effect crankshaft sealing – correct?

I’m used to rubber-lip or labyrinth seals in 2-stroke motors.. but these TD20 seem to have nothing of the sort. Then again, most 2-stroke motors don’t have plain bearing bottom ends – they generally use ball & roller bearings, which do require sealing.

May 1, 2015 at 12:42 pm #15171legendre,

You are correct that there are no crankcase seals, so crankcase sealing relies on those close tolerances and proper use of the correct crankcase sealant.

I went back and read your original thread "Johnson 5hp TD20 ignition timing facts & figures?" and I read a couple of things that got my attention. One was that you saw evidence of someone splitting the crankcase halves with a screwdriver or chisel. I don’t know what kind of damage that could have caused to the mating surfaces.

Another thing was that you sealed up the crankcase with Permatex Ultra Gray. Although I have not used that product, I would question whether it is recommended for non-gasket applications where such tight tolerances are involved. It may have too many fillers, silicone, etc., that could prevent the crankcase halves from achieving the proper tolerances.

When I had questions about what sealant to use, I asked Mumbles, and he recommended Permatex 51531 Anaerobic Flange Sealant.

http://www.ebay.com/itm/Permatex-51531- … ad&vxp=mtr

This is a very thin purple sealant without fillers that is made for this application, and it has worked well for me. Permatex also makes a slightly thicker anaerobic sealant that is better adapted to gearcases and two piece tanks. That is no. 51813, and it is red in color.

Good surface prep and proper torque are very important. I think I am just about out of ideas here, hopefully someone else has an idea that will help.

Brent

May 3, 2015 at 2:41 am #15241Howdy Brent,

Well that’s (at least) two of us who are out of ideas. This one has me truly and genuinely stumped.. quite the unexpected challenge from such a simple piece of machinery. I mean to say, I just got through a fairly involved service & repair job on one of these – it’s a Model ‘J’, ca. 1926 – so it’s not like this is my first rodeo.

I hear your concerns about the crank sealer I used, and I’m willing to look at just about anything at this point. The Ultra Grey +is+ spec’d for high-torque applications, and I’ve come to understand that it’s a relatively good replacement for the product I’d typically use in this application – which is Yamabond 4 (or the ThreeBond equivalent). That said, it +is+ a form of RTV silicone, and I’ve never really been a big fan of those materials.. The old blue crap from the 70s wasn’t very good at all – we called it "Form-A-Leak" and you probably did, too.

Thing is, the motor has developed a clear pattern. It will start off great on one pull, run like a champ at high-ish speed (START setting range) for a minute or less, and then suddenly it all falls apart. It loses speed, it stumbles, misfires.. begs for more throttle, but even full throt isn’t enough to keep it alive. Then it kills and doesn’t want to restart easily.. at all. Pull the plugs, they look wet.. almost water-wet, but I can smell gas.

Leave it sit for a day, and it will perform the same act again. And this is now 100% localized to the short-block.. and the lower unit. Literally +everything+ has been swapped & tried between the two motors except for the short-block and the lower unit. And that even includes the downtube / handle assy!

May 3, 2015 at 5:02 pm #15264FWIW, I’ve figured out the issue with the water running down the wrong area of the downtube. It’s actually part of the stream from the tell-tale that’s hitting one of the thrust yoke brackets, running down along the bracket, then down the starboard side of the tube.

And I confirmed there is a spray issuing from the two holes on the port side of the tube, as well – so that part is fine too.

-

AuthorPosts

- You must be logged in to reply to this topic.