Home › Forum › Ask A Member › Synching carbs and ignition on 1972 85 hp V4

- This topic has 11 replies, 3 voices, and was last updated 5 years, 7 months ago by

fleetwin.

-

AuthorPosts

-

August 25, 2018 at 1:12 pm #10968

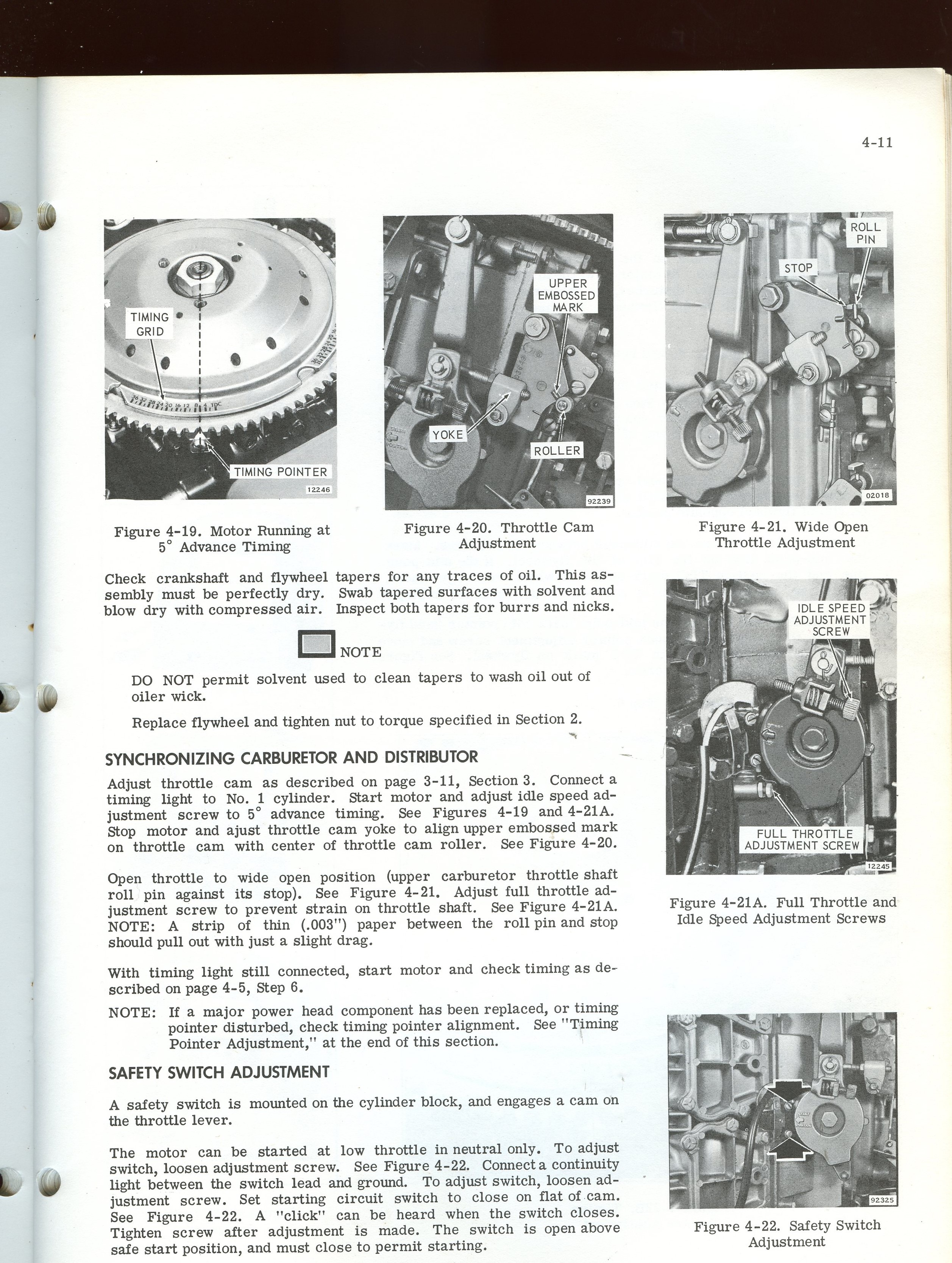

The manual I have (downloaded from boatinfo) says to use a timing light and "Adjust the idle speed adjustment screw to 5 deg advance timing." etc. I don’t really understand this.

Is it possible that someone could post a couple of pages with the linkage and how to adjust it. Choke, throttle, ignition? Would be much appreciated.

August 25, 2018 at 2:31 pm #81759August 25, 2018 at 3:03 pm #81763OK, well I think there is some confusion here….I read the OMC instructions Frank posted about the 5degree BTDC adjustment, but that is confusing also. This step refers to an earlier adjustment/set up, which I think is getting confused for idle speed…

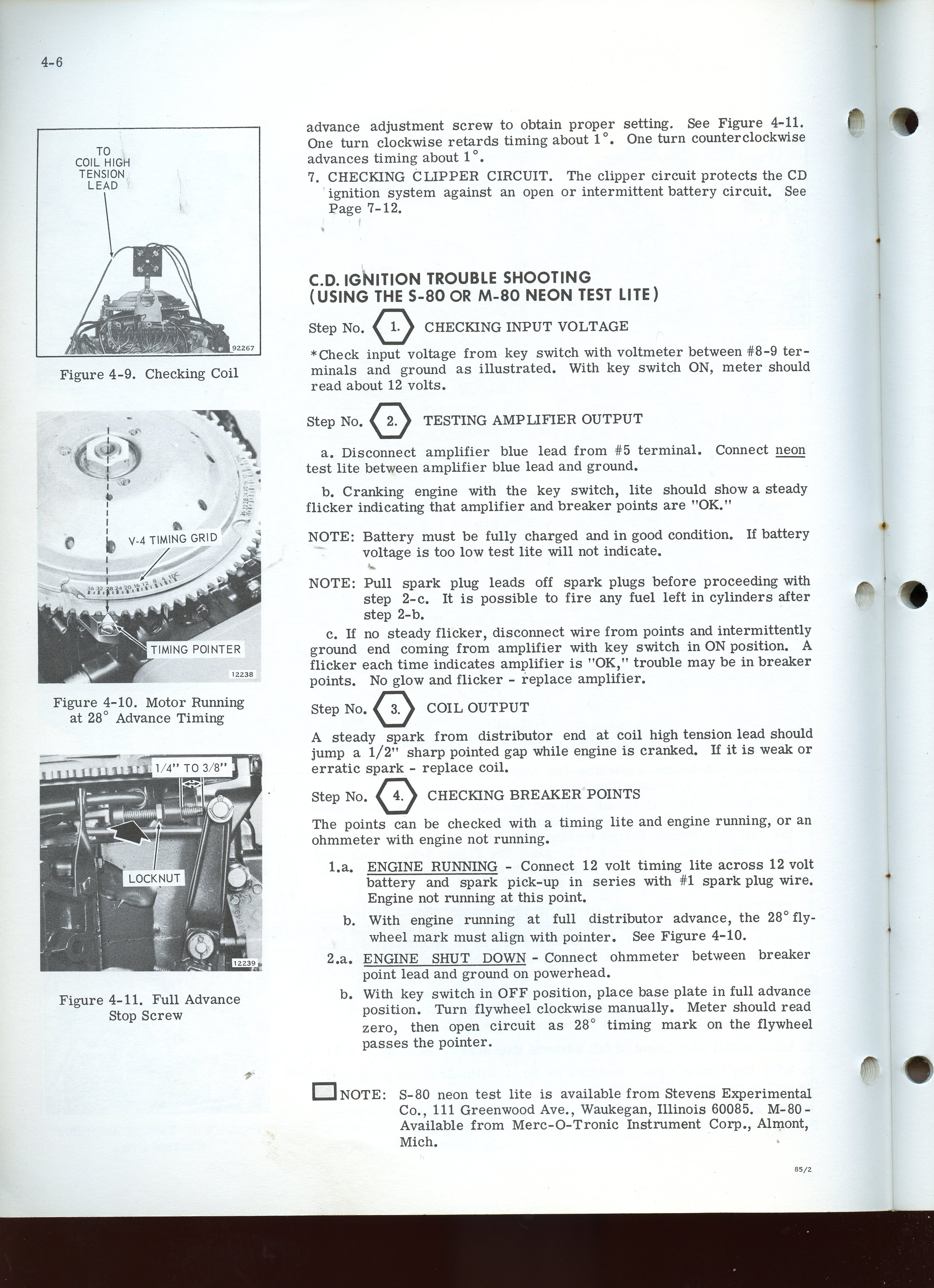

The 5 degree BTDC adjustment is for the "pick up timing adjustment", which is not the same thing as setting the idle speed. There is no timing spec for idle speed on these engines, proper idle speed is controlled by screwing the idle speed control screw in/out slightly to set proper idle RPM in gear. When these engines are idling, the throttle cam should not be touching the roller.

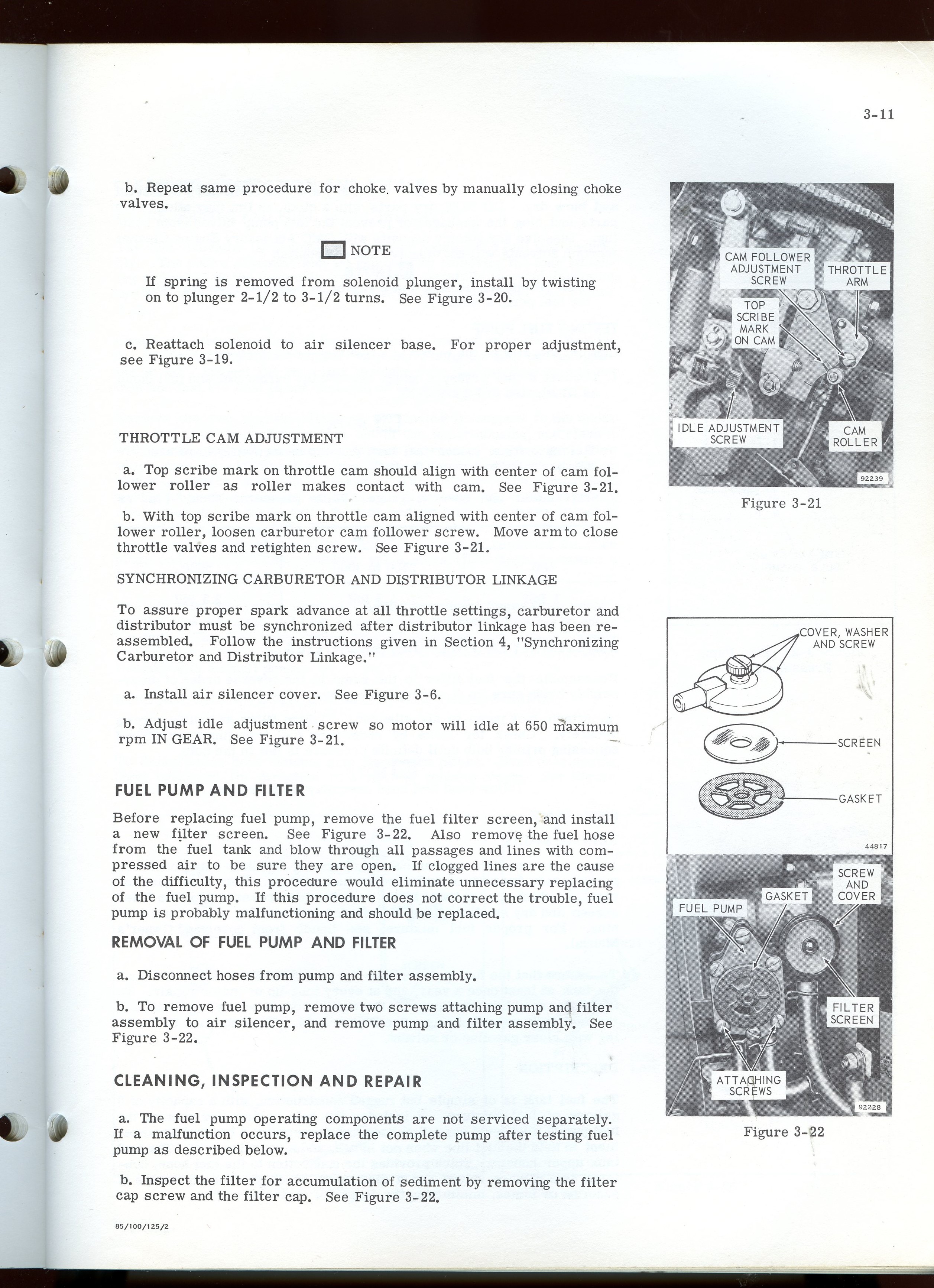

The 5 degree BTDC pick up timing is checked when the scribed line on the throttle cam is bisecting the throttle roller, when the cam just starts to open the carb butterflies, this is an off idle speed setting. The pick up timing is adjusted by rotating the plastic yoke in/out on the threaded throttle linkage, not by turning the idle speed screw in/out.

These adjustments are not difficult but can be confusing. The sync adjustments must be performed in order, starting with checking the TDC pointer. Skipping a step, or performing steps out of order will create confusion and running issues.August 25, 2018 at 4:02 pm #81767Thanks Frank, fleetwin.

Those pages are better than what I had. Yes, there is confusion. I took the carbs off a year ago and failed, apparently, to take a set of pics and measurements, and these are not simple engines.

August 25, 2018 at 4:51 pm #81770To make it simpler in our minds, just relate all this to something we are familiar with. Take an old twin motor with a sliding spark advance/throttle on the front for example. You would put the speed control lever slightly to the right of center, and there would be a mark on the throttle cam that would align with a roller on the carb link, and the carb would just barely be ready to start opening. With me so far??

OK, then. Putting the speed control lever slightly to the right of center equates with setting the timer base to 5 degrees. Not touching that again, the mark on the cam is supposed to be centered on the roller and the carbs would be just ready to start to open (two adjustments, one to center cam on roller and one to make carbs just ready to open)

Make sense now?

August 26, 2018 at 5:15 pm #81818Good point Frank, I overlooked the fact that the cam does have two lines on it…Only the line/mark towards the top of the cam is used for synchronization…

I am assuming you did not mess with any of the cam linkage adjustments when you had the carbs off, correct? So, I am thinking most of those adjustments are probably "OK"/close enough. Did you loosen the carb roller clamp screw while you had the carbs off? If not, its location is probably "OK/close enough" also.

Check to see that the cam is not touching the roller at dead idle. Next, make sure both carbs are completely closed at dead idle. This is probably done most effectively by looking inside the carburetor throats. The engine will sneeze lean if one/both carbs are cracked open/even slightly at idle. The two carbs must open at the same time (be synchronized together), this is accomplished by adjusting that little clamp that connects the two butterfly rods. This adjustment is a tricky one….In the quest of perfection (both carbs opening at the same time), the linkage rod often gets "preloaded", resulting in one carb hanging open very slightly at dead idle. On the other side of the spectrum is too much slop in the linkage resulting in one carb starting to open before the other, this usually results in rough/rich running at off idle speeds. It is near impossible to obtain the "perfect fadjustment/synchronization", especially on an older engine with worn linkages/throttle shafts. So, it is better to settle for a bit of slop in the linkage, than the lean spit/stalling that is caused by having one/both throttle plates cracked open (even just slightly) at dead idle.

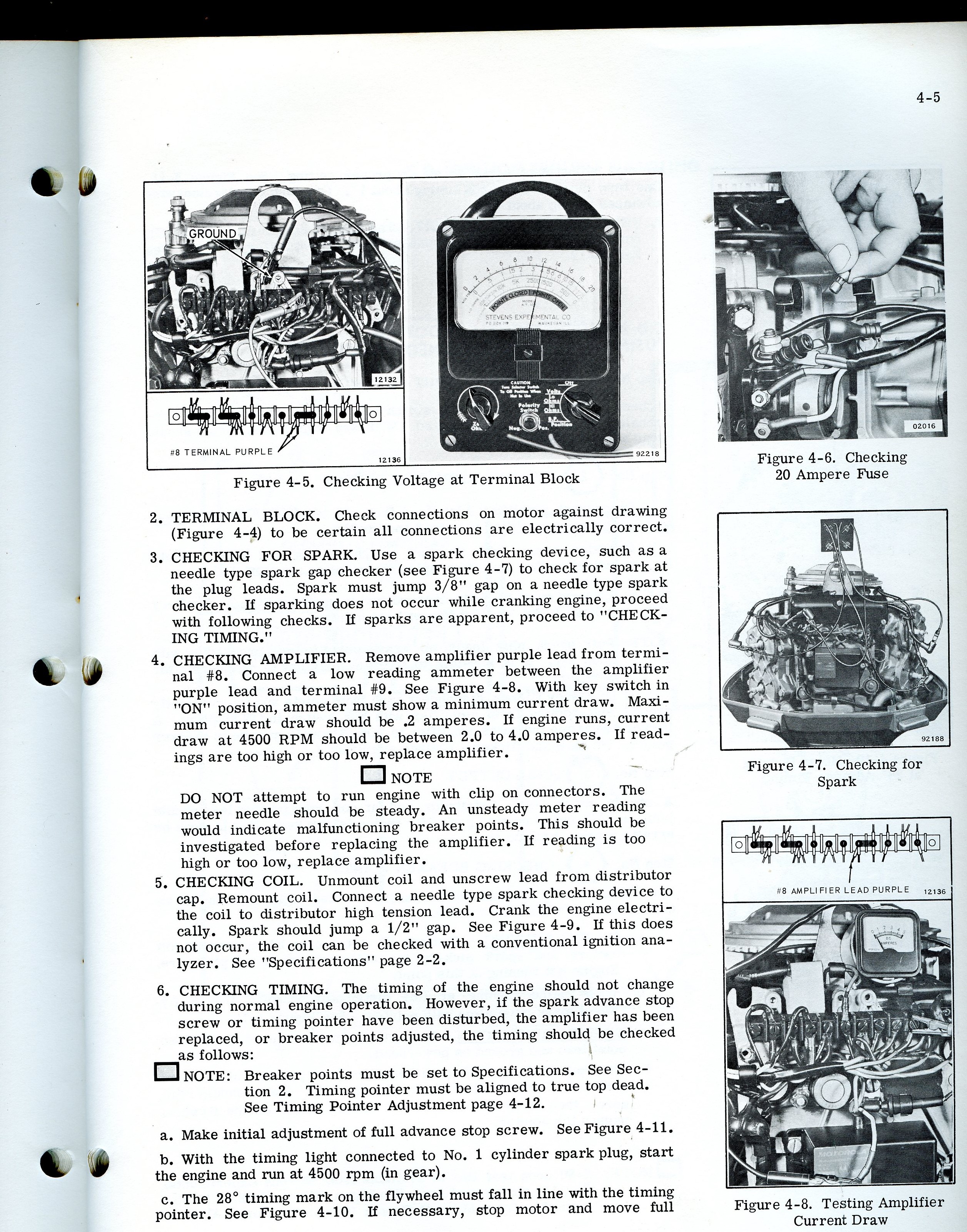

The other thing to check is that the throttle are not "preloaded" at WOT. There is a roll pin in each throttle shaft that is visible. Push the throttle linkage to WOT (perhaps an assistant can hold it there). The roll pins should not be jammed against the boss in the carb body casting. There should be just a bit of clearance between the roll pins and the carb body boss’. Jamming the roll pins against the casting boss’ will wear the throttle shafts and possibly knock your sync adjustments out of whack. On the other hand, if the roll pins don’t come near the carb boss at WOT, this is saying that the carbs are not opening completely at WOT. If this is the case, then I would be worried that someone has messed with the other linkage adjustments. The wide open throttle stop is adjusted by the small little set screw in the block that the bottom of throttle arm butts up against at WOT….

I realize this is frustrating, very tough to communicate/understand using the written word. The process is not difficult, but it is critical to follow the instructions in order, starting at step one. Altering one adjustment, can have an adverse affect on a previous adjustment if the process is done out of order.August 26, 2018 at 6:10 pm #81820This guidance is clear and sensible. I’d say that in a general way it applies to pretty much any multiple carb setup.

This motor shows no throttle shaft/bore wear at all, so I’m pretty confident I can get it set up well, mechanically. I do have my doubts about the fixed idle mixture, which leaves no options for adjustment to compensate for anything.

August 26, 2018 at 6:16 pm #81821These old cross flows are pretty tolerant to abuse/altitude/weather conditions. The fixed idle jets are usually not an issue, unlike on some of the newer engines. And, on this engine, they are easy to access and clean….

I’m sure you will get it set up just fine and it will run great.August 26, 2018 at 6:44 pm #81824Actually, the fixed idle mixture jets were a huge improvement over previous models that had adjustable idle needles, one for each cylinder. Nobody but nobody could get all four of them just right.

August 27, 2018 at 1:49 am #81858It looks like most of the linkage adjustments have been messed with, so I need to go through them all systematically. One question: There is a "start" position index mark on the lever but It’s not obvious what it’s supposed to line up with.

-

AuthorPosts

- You must be logged in to reply to this topic.