Home › Forum › Ask A Member › Transom wood

- This topic has 14 replies, 12 voices, and was last updated 5 years, 7 months ago by

fountain.

fountain.

-

AuthorPosts

-

September 17, 2018 at 2:38 am #11238

Inquiries have been made as to use of treated wood restoring aluminum boat transoms. Our members have strongly suggested that its’ use would initiate corrosion, and I concur.

I purchased a 20 year old boat Monday built by a major manufacturer(10 year warranty). It is a little weathered and used in fresh water, not damaged from abuse. On close inspection, the transom had several perforations from internal corrosion caused by use of treated wood. This is original factory production.

I haven’t seen it this bad on boats up to 70 years old using better materials of their day. I am considering tearing out the whole transom and installing white oak, which should have been done in the first place.September 17, 2018 at 12:23 pm #83030Good idea to keep this topic fresh Roger. It could mean the difference between a restoration and a issue that can cause the loss of a hull. I have a friend who had a G-3, fairly new boat that had to have the boat replaced as the hull corroded through at the floor line. They had used pressure treated plywood in the floor.

Steve

September 17, 2018 at 4:19 pm #83053Be aware that breathing smoke from a pressure treated wood fire can be fatel. . . 😮

September 17, 2018 at 11:19 pm #83077

September 17, 2018 at 11:19 pm #83077several perforations—WOW!

2Fast4Me

September 18, 2018 at 6:45 pm #83127Yes, I concur as well. My first boat was a 12 foot Duracraft rowboat. The PO had replaced the transom wood with pressure treated lumber. It was a sad looking job, so I replaced it again myself after getting the boat. When I removed the wood that was on it many holes had been eaten through the aluminum transom. I did a bit of research as I was doing this work as this was my first time doing it. I found out quickly about the effect of pressure treated lumber on aluminum. When I replaced it I used hardwood inside and a piece of construction grade plywood outside. several coats of outdoor polyurethane on both boards prior to replacement. I used 100% silicone caulk to seal the outer board and all the bolt holes when I put it back together. it didn’t leak and it was only rated for 8hp. It had a Merc 9.8 on it and I ran it that way one time before I bought a bigger boat. It held the 9.8 OK, but being a newbie at the time, that was way too much motor on that boat for me. I see visions of that Swiss cheese transom every time I think of pressure treated lumber.

-BenOldJohnnyRude on YouTube

September 18, 2018 at 11:36 pm #83134The older pressure treating chemicals were copper – arsenic based chemical compounds. Copper and aluminum don’t play together nice in wet environments. They are using something different these days, not sure what or if friendlier to aluminum. I do know that the deck builder guys had to switch to stainless steel or plastic coated fasteners cause the new stuff was eating steel fasteners.

Joe B

September 19, 2018 at 12:01 am #83135The problem with pressure treated wood is it is always pine!—Low quality pine. Pine is not a dense wood and for areas without close bracing, is not structurally strong.

Transoms should be white oak on outboards.

George

September 19, 2018 at 12:24 am #83136quote JoeCB:The older pressure treating chemicals were copper – arsenic based chemical compounds. Copper and aluminum don’t play together nice in wet environments. They are using something different these days, not sure what or if friendlier to aluminum. I do know that the deck builder guys had to switch to stainless steel or plastic coated fasteners cause the new stuff was eating steel fasteners.Joe B

Still copper, its just the other chemicals are different. That’s why new stuff also has the green coloration

I want to say that the old stuff used a copper-arsenic base?

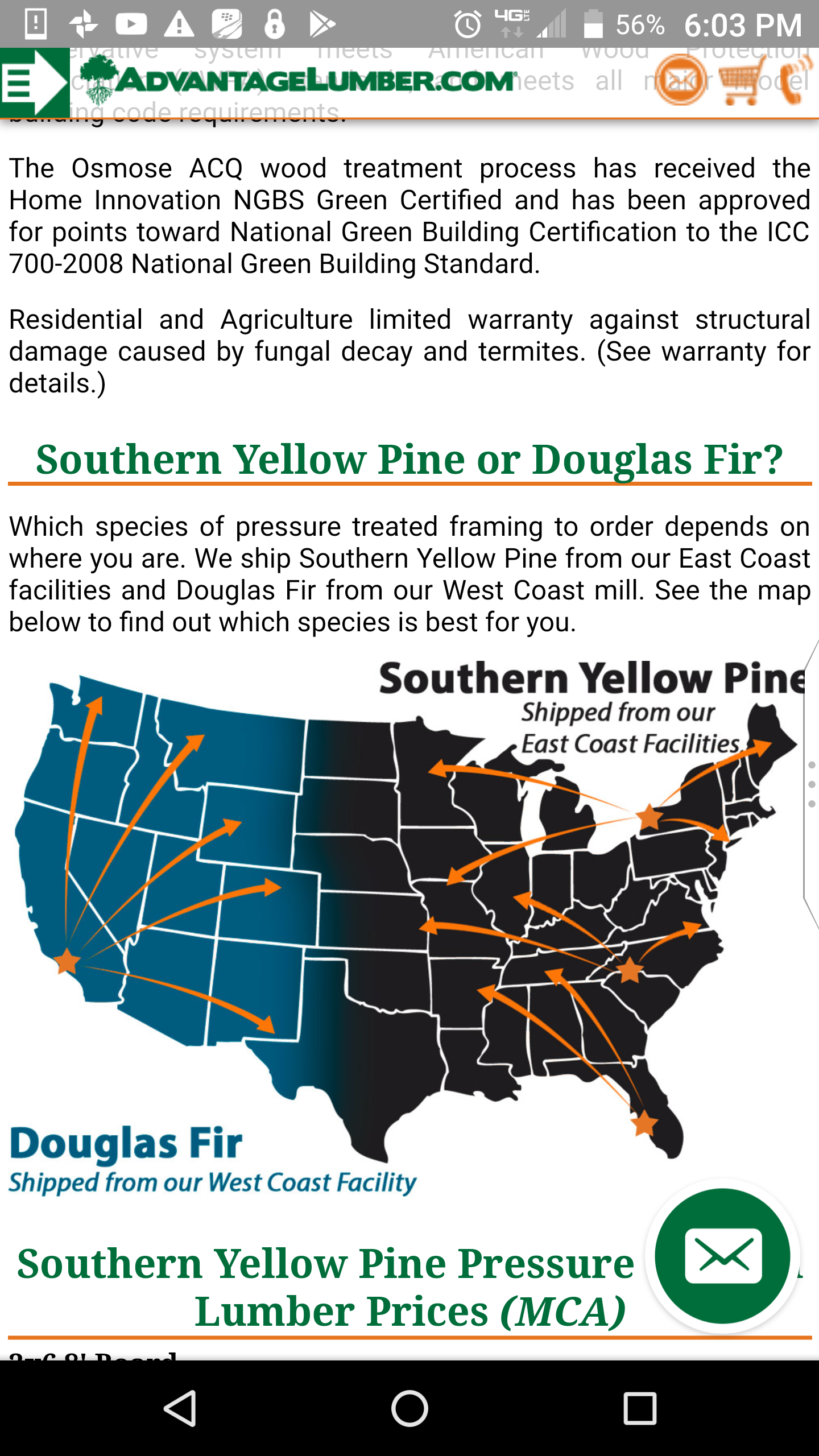

September 19, 2018 at 2:01 am #83150Out in the wild west or at least the Pacific Northwest ,our mills use Douglas Fir for most framing material and some Hemlock too.

I believe the same is the case in our friendly country north of us. 🙂"Some people want to know how a watch works, others just want to know what time it is"

Robbie RobertsonSeptember 19, 2018 at 11:29 am #83159I have a 1982 Alumacraft rivited Jon boat which needed the transom wood replaced in the early 90’s. I replaced the original plywood with five quarter (1 1/4” thick) Marine plywood, which I painted prior installation. I still have this boat, it is stored outside uncovered, and the transom wood is still good.

Regarding treated lumber and aluminum. I used a piece of treated wood repairing the facia board on my fishing camp. A few years later the aluminum trim over this board started corroding severely. Keep treated lumber separated from aluminum.

Jim

-

AuthorPosts

- You must be logged in to reply to this topic.