Home › Forum › Ask A Member › TUBE BENDING

- This topic has 28 replies, 17 voices, and was last updated 6 years, 3 months ago by

jeff-register.

-

AuthorPosts

-

December 28, 2017 at 12:00 am #69034

Tubs,I would say it was pretty soft, equal to copper.

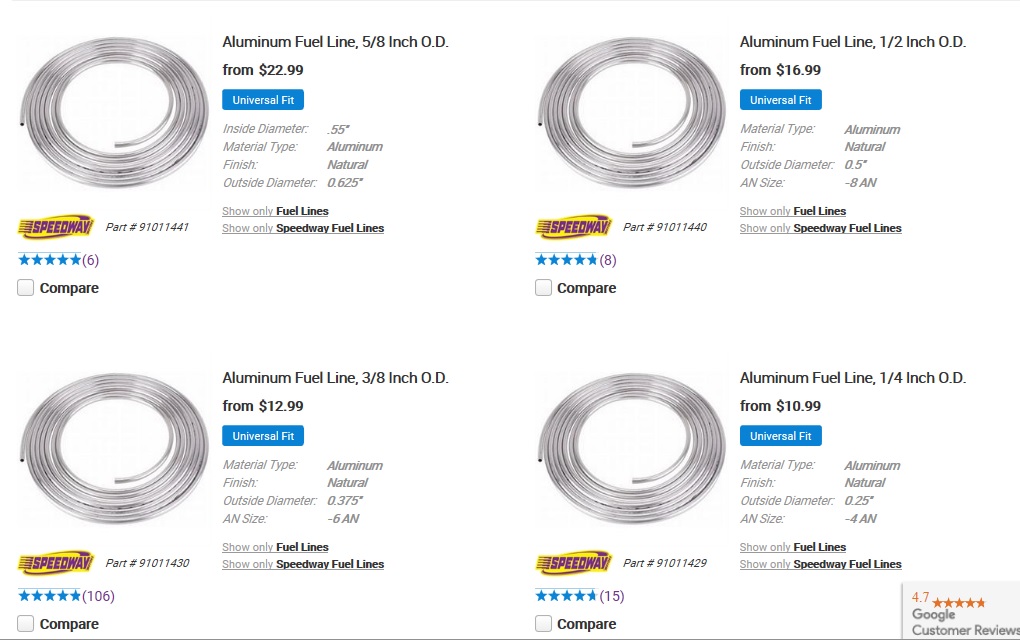

Bob DDecember 29, 2017 at 3:43 pm #69063Back in the late 70’s we started using this

for fuel line. This may be the same as what

you have bought. It was so much easier to

use than the steel line but in the beginning

we questioned whether it would hold up as

it seems to be even a little softer than copper.

Going on to forty years an there was never

a failure that we know of. You can polish

it which would simulate the nickel plating.

Cant find it in 5/16" though.

Here’s some eBay links.https://www.ebay.com/itm/Speedway-Motor … 1438.l2649

https://www.ebay.com/itm/Challenger-Alu … 1438.l2649

It list for less on the Speedway sight but don’t know what shipping will do to the total.

December 29, 2017 at 6:50 pm #69073Wall thickness not given…..

December 30, 2017 at 1:56 am #69091quote outbdnut2:Copper is soft….up to a point – you bend or otherwise stress it too far, it work-hardens and gets brittle.

DaveCopper will work harden when being bent or hammered on. To soften it again heat it up kinda red and quench in water just the opposite of steel. I had to do some tricky bending on copper water pipe ( packed with sand ) where I had to soften it several times. When I was done forming, the pipe was dead soft from heating and quenching to harden it back I just wiggled it back and forth and you could feel it harden back up. Bill,

December 30, 2017 at 2:10 am #69093If you want to bend small copper tubing tight radius 1/4” to 3/8” I would just fill it with melted lead or cheap solder just heat the copper and solder and fill it as a liquid then find something round of the approximate radius and bend the tubing around it then take a propane torch and melt the solder or lead out. I have several tubing benders and small V belt type pulleys I have accumulated over the years to aid in bending. If possible I will try doing it cold but sometimes the fitting is to close to bend and then you have to use your imagination. Bill,

December 30, 2017 at 8:54 pm #69111Tubs, good links. I will use them in the future. Much cheaper than what I bought which was sold individually by the foot.

Bob DDecember 31, 2017 at 4:41 pm #69125I’ve tried filling the tubing with sand (no heat) Didn’t help.

I believe filling the tubing with solder should work but

while the majority will run out not all of it will. Trying

to blow it out may work if you reheat the tube several

times. My thinking is if you whip the hot tube most of

the solder should come out. To much trouble for me.

I was thinking of trying to melt some trimmer line to

fill a straight piece of tubing maybe 6" long. Then if

I could get it out I would spray it with some kind of

lubricant, sticking in some tubing, make the bend, and

see if I could pull it out. The biggest problem with this

is melting the trimmer line. Thinking is probably as far

as I’ll go here.This is new to me.

quote Billy J:To soften it again heat it up kinda red and quench in water just the opposite of steel.

I will definitely be giving this a try to see if I can get the same result.December 31, 2017 at 6:58 pm #69127how about fill with sand then add solder after the sand both ends just put enough in for a little more than the bend

January 1, 2018 at 1:01 am #69137Bet it stunk…plastic melted = toxic fumes. I’ll buy a 90 & correct,

-

AuthorPosts

- You must be logged in to reply to this topic.