Home › Forum › Ask A Member › Water Tube Gale 12S13

- This topic has 8 replies, 3 voices, and was last updated 6 years, 2 months ago by

crowsbeak.

-

AuthorPosts

-

February 24, 2018 at 9:37 pm #9290

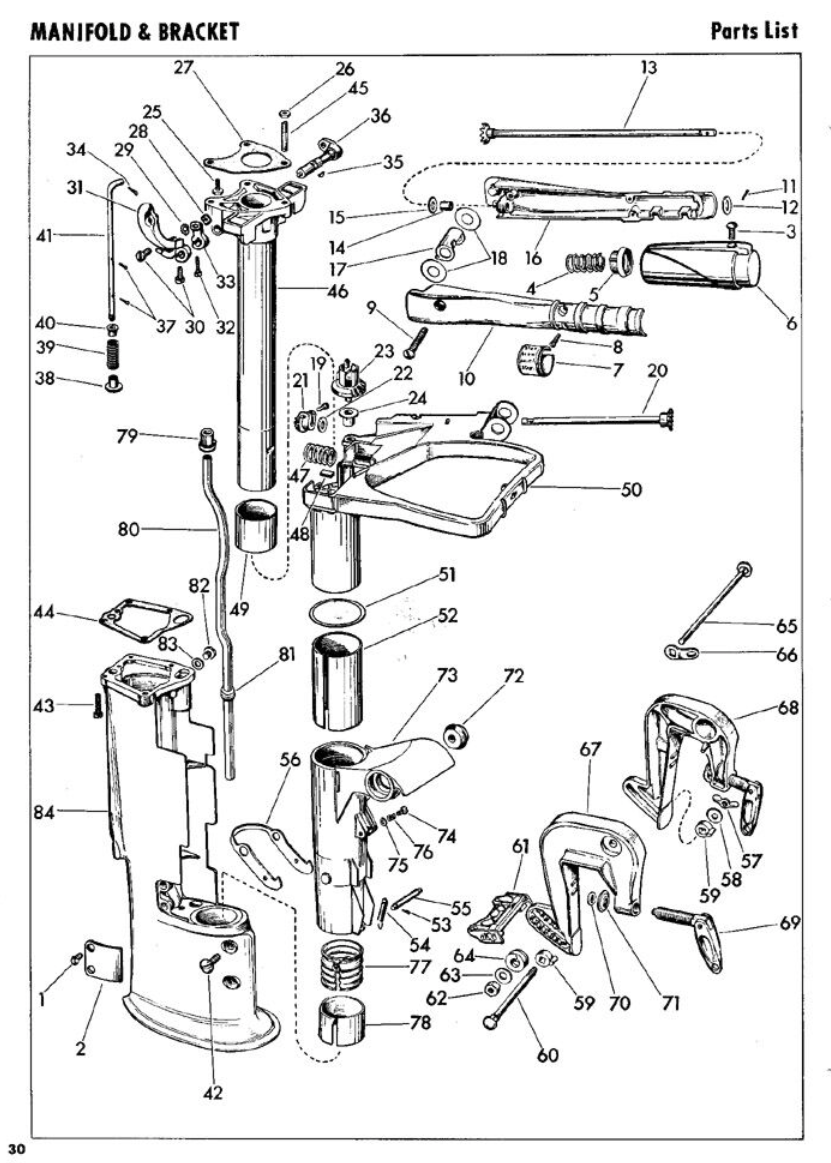

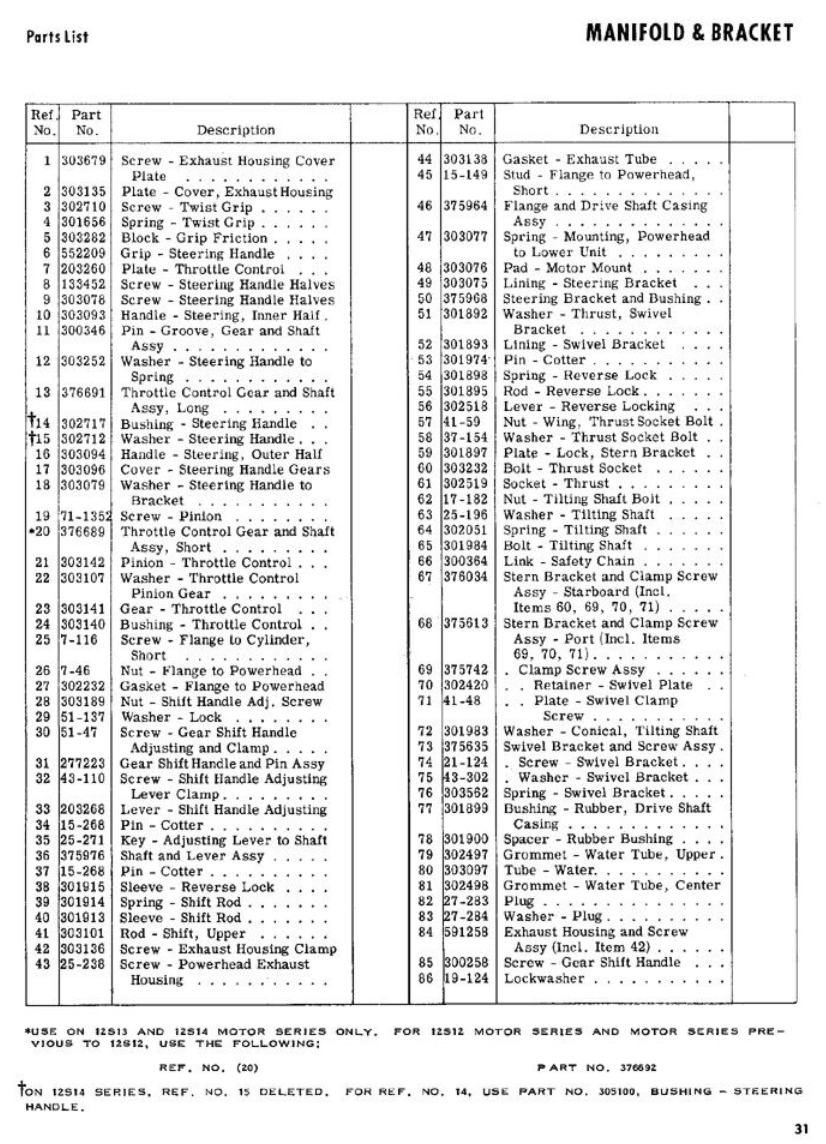

Hey everyone I’m working on rebuilding a Gale 12S13 and the upper water tube grommet (302497)is beginning to crumble so I am looking to replace it. How do you get the copper water tube (part 303097) to slide down the exhaust leg far enough to remove the upper grommet? The copper is so soft I don’t want to bend anything. Is there a tool you can use to drive it down without mushrooming the top of the tube? When it is out what do you use to push the water tube back up into the grommet? Any help would be appreciated.

Edit, I have the whole exhaust leg taken apart I can access the entire length of water tube.

1954 Evinrude 7.5 HP

1954 Evinrude 15 HP

1954 Gale 12 HP

1956 Gale 12 HP

1956 Evinrude 5.5 HP

1960 Evinrude 18 HP

1973 Johnson 6 HPFebruary 24, 2018 at 10:21 pm #71536Dang if I know, never been there. But looking at the diagram and guessing, it appears there is a center grommet too. My guess is that it is petrified and preventing the tube from sliding up and down through it. Maybe some oil to make it slippery, or more likely you will have to deal with that hard rubber. Also guessing you do have the lower unit removed, right?

February 25, 2018 at 12:20 am #71546Thanks for the Reply Frank. Yes the whole thing is tore down and I have sprayed it with silicone lube and have gotten the tube to slide about 1/4 inch but it is very tight and I don’t want to bend/break anything. It does have a center grommet like you suggest. The Gale manual doesn’t have any good directions either so I can’t find any factory recommended method.

1954 Evinrude 7.5 HP

1954 Evinrude 15 HP

1954 Gale 12 HP

1956 Gale 12 HP

1956 Evinrude 5.5 HP

1960 Evinrude 18 HP

1973 Johnson 6 HPFebruary 25, 2018 at 1:03 am #71547The upper grommet (302497) has predictions which engage holes in the casting. The long tool used to install these fit the inside of the grommet and is ground away on opposite sides to allow these projections to retract. When in place , it is then twisted to push these projections into there respective holes. A lubricant makes this easier. but some oils react with the grommet to bond it the the copper making future removal difficult. The upper grommet can be carved away to get at the copper tube. When the new grommets are in place make sure the water tube is the proper length and has NO rough edges. I like to use KY jelly as it does not react to rubber. Be sure everything lines up properly when installing the lower unit . . . 😉

Gale mod 12S13

February 25, 2018 at 1:38 am #71554

February 25, 2018 at 1:38 am #71554I think you are going to have to use some well-engineered violence on that center grommet in order to save the more expensive water tube.

February 25, 2018 at 1:39 am #71555Thanks Gary. Sounds like I need to try to carefully carve the upper grommet away, slide the tube down, install new grommet and slide the tube up trying not to mar up the copper. Do you use anything to grip the copper tube other than your hand?

1954 Evinrude 7.5 HP

1954 Evinrude 15 HP

1954 Gale 12 HP

1956 Gale 12 HP

1956 Evinrude 5.5 HP

1960 Evinrude 18 HP

1973 Johnson 6 HPFebruary 25, 2018 at 1:44 am #71556Frank, any thoughts on how to engineer that violence would be appreciated. I thought about trying to attach a pipe clamp in the middle of the tube to try to use to tap down on the tube. Did they use anything special when these were installed at the factory?

1954 Evinrude 7.5 HP

1954 Evinrude 15 HP

1954 Gale 12 HP

1956 Gale 12 HP

1956 Evinrude 5.5 HP

1960 Evinrude 18 HP

1973 Johnson 6 HPFebruary 25, 2018 at 1:55 am #71557Brand new parts are always easier to handle. A layer of rubberized friction tape makes them easier to grasp. . . 😀

February 25, 2018 at 12:50 pm #71573

February 25, 2018 at 12:50 pm #71573I got it free last night. Sprayed more lube and kept twisting the water tube back and forth and then was finally able to slide the tube down. Cleaned both ends up wit Emory cloth to make sure they are perfectly smooth and ready for re installation. Good idea on the friction tape Garry and thank you for the parts diagram.

1954 Evinrude 7.5 HP

1954 Evinrude 15 HP

1954 Gale 12 HP

1956 Gale 12 HP

1956 Evinrude 5.5 HP

1960 Evinrude 18 HP

1973 Johnson 6 HP -

AuthorPosts

- You must be logged in to reply to this topic.