Home › Forum › Ask A Member › 1956 Evinrude 15hp Throttle Q and Fouling

- This topic has 26 replies, 4 voices, and was last updated 3 years, 11 months ago by

fleetwin.

-

AuthorPosts

-

June 7, 2021 at 8:59 pm #239679

Two questions here as referenced in the topic title, but will give a short known history of outboard….

I picked up a 1956 Evinrude 15hp late last October 2020. History is a bit thin on outboard, but looks to have always been a Missouri motor with an antique metal Missouri license plate affixed to the power head. We have put it on a 12 ft tunnel hull Livingston with fun success. It was supposed to be tuned up by a mechanic in Booneville, MO “allegedly”. It had a hacked fuel pump addition from the front reed area that wasn’t enough to run at high speed for long? I replaced it with a pump that attaches to bypass and fuels nicely now. Compression on both cylinders in mid 90s. Running Champion J6c plugs. Using Lucas blended synthetic marine oil at 24:1 and 91 octane gas w no ethanol. I have also adjusted high/idle screws to run appropriately on this mix.

After 3 straight weeks of wringing the heck out of this little outboard and last full day of our vacation, I was a bit short on Lucas oil and picked up a random marina 8oz two stroke bottle mixed with a little bit of Lucas to do 32:1 on 5 gallons. We used 3 gallons of this and then ended up fouling the bottom spark plug. Replaced with a new plug, ran great again for a few mins and went back to one cylinder. Fired up fine the next morning to load up on trailer. Came home and pulled plugs, bottom newer plug looks maybe more oily but tip is dry. Holding plug against bolt and pulling starter rope makes a nice blue spark on both wires. Did I mess something up with the oil mix or that unrelated?

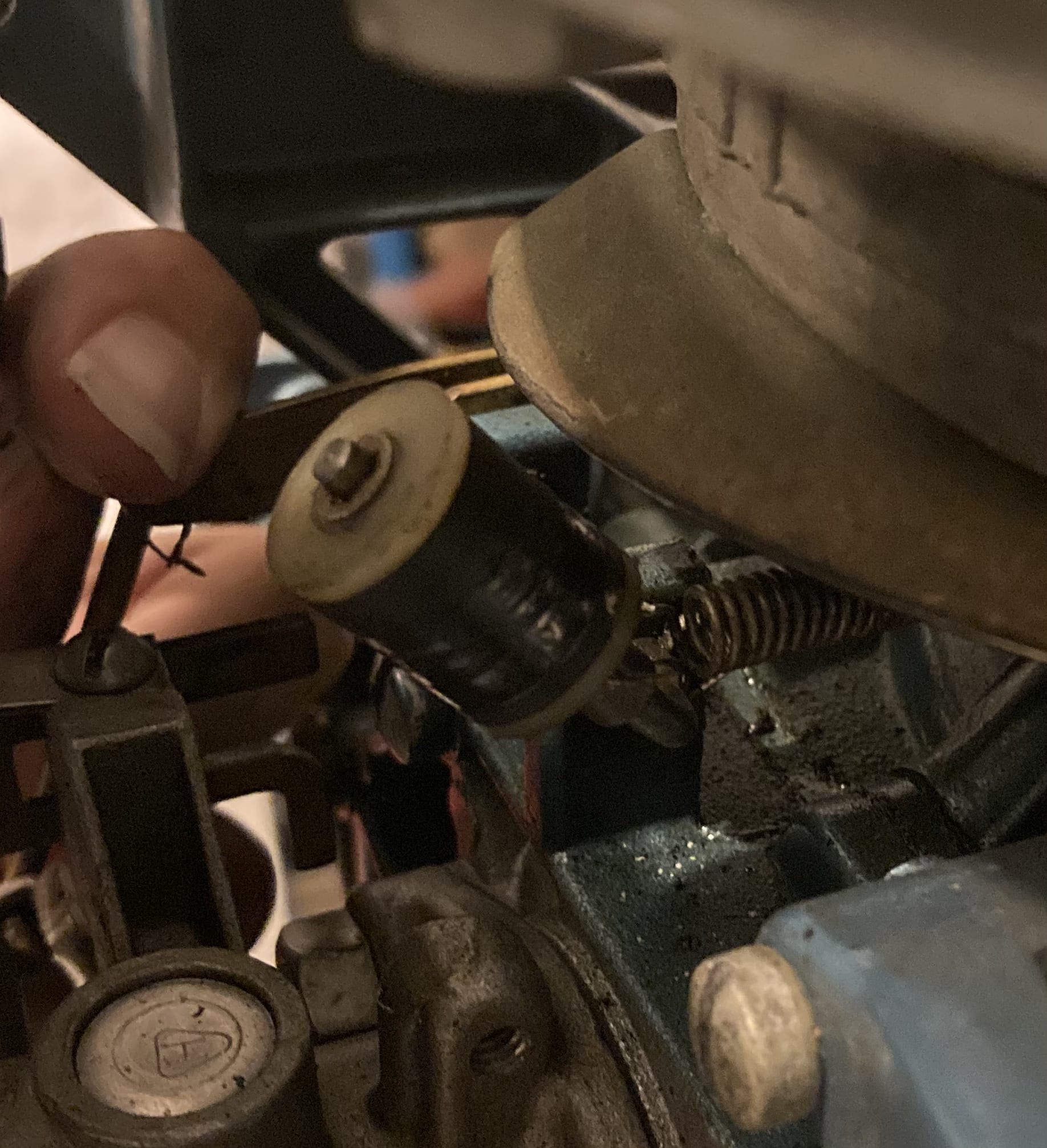

Different question, on the throttle twisted as far as it will twist it looks like there is still and inch or so left on the timing plate that pushes the carb throttle open and a fingers worth of additional movement that could be had on the throttle opening. Does this sound like correct positioning? Attached photo of additional play on the cam roller.

-

This topic was modified 4 years, 1 month ago by

Mumbles.

Mumbles.

June 7, 2021 at 9:25 pm #239681stuff to read see parts 1-6 at the bottom reviving a 1956 15hp 🙂

Joining AOMCI has priviledges 🙂

June 7, 2021 at 9:29 pm #239682throttle START ====> Roller on the notch mark on the cam cam can be unbolted and dragged forward to just touch the roller

Joining AOMCI has priviledges 🙂

June 7, 2021 at 10:14 pm #239686Thanks, missing the little label on the throttle that says “start”… is there another way to ascertain that? I see notch on the cam plate

June 8, 2021 at 11:57 am #239715Well, just because it sparks when you check with the plugs removed, does not ensure you have good strong spark while running under compression…Try those inline neon testers while running when it starts to mess up….Have you had a look at the coils? Old coils tend to crack, you can have a quick look pretty easily by removing the recoil and the little inspection plate on top of the flywheel…I just reread your post, where you indicate the engine had a recent “tune up”. Perhaps they messed up the ignition. You swapped the fuel pump back to the bypass cover, and plugged the intake manifold port. Does it look like someone had the intake manifold off? Perhaps your fuel pump is leaking past the diaphragm into the cylinder, but am guessing the fuel pump is mounted on the top cylinder.

The only other thing that comes to mind is that this era of 15hps used a regular lower seal instead of the usual carbon seal set up…The regular seals tend to rust up and come apart over time…Needless to say, there is no way of inspecting without pulling the powerhead, which I don’t want you to do until all other possibilities have been exhausted. The only other thing that might indicate a bad lower seal is the presence of water on the plug(s).June 8, 2021 at 7:31 pm #239739Thanks, haven’t seen one of those neon testers before and I’ll pick one up. I’ll take the recoil off tonight and have a look, I’m curious if the “tune-up” or any “tune-up” ever replaced the coils. We ran about 30 gallons of gas thru the motor in 3 weeks of vacation, so it was working pretty darn well… until half-way thru the last batch of different gas mix (see original post)… wasn’t sure if it was coincidence or not.

Fuel pump is in the top bypass, intake looks like it hasn’t been removed in decades. I suspect the recent tune-up was a carb clean, plugs, some rickety fuel pump change and lower unit gear oil.

I did order a few J8C plugs to try? Also wondering if I should try decarbing the engine. Going back to the lake in two weeks and trying to button up any issues so we can fish the heck out of this boat again.

June 8, 2021 at 7:45 pm #239741I would not use the J8C plugs, unless you plan on idling all day long, they are a bit too hot for high speed running. I’m sure the boatyard replaced the coils if they were cracked, kind of hard to miss that. But, they may have misrouted ignition leads under the flywheel, which may have eventually rubbed through….

The fuel pump is on the top bypass, so an issue there would be affecting the top cylinder….You mention that the intake looks untouched, so I guess issues there are not likely. What about the fuel pump pressure port that comes off the intake, is it plugged off securely? You could try decarbonizing, but that is probably not an issue unless you have been idling/trolling excessively.

Again, any evidence of water on the plug(s)?

I’m not sure about whatever lucas oil blend you are using, you mentioned using some generic stuff also, perhaps that is an issue.

Finally, this is a relatively low compression engine, there is probably no benefit from using the higher octane fuel…But, I realize you are using it mostly due to the lack of ethanol.

Finally, how does the engine run before the lower plug gets fouled? Idle OK?-

This reply was modified 4 years, 1 month ago by

fleetwin.

June 9, 2021 at 6:39 am #239761June 9, 2021 at 7:18 am #239770see bleeder 2-1 initial file was wrong…

Good point, forgot about the drain system…..

June 9, 2021 at 7:55 am #239774in the coming weeks I’ll be checking out my friend’s fouling… 5.5 and will clean out the bleeder circuit if only for peace of mind…and will report back asa Ican .

a shot carb cleaner small wire and 90 psi should see to fixing any blockage. 🙂

Joining AOMCI has priviledges 🙂

-

This topic was modified 4 years, 1 month ago by

-

AuthorPosts

- You must be logged in to reply to this topic.