Home › Forum › Ask A Member › 1961 Johnson 40 (RDSL-23) stops pumping water

- This topic has 37 replies, 9 voices, and was last updated 2 years, 9 months ago by

fleetwin.

-

AuthorPosts

-

August 2, 2021 at 4:51 am #244101August 2, 2021 at 5:40 am #244105

If you can mount the engine on a test boat with a 15 inch transom, that’s okay. You will loose five inches of head pressure, I suppose, which may confuse things a bit. It would pump better just because of that, I suppose. But just getting the lower unit into nice, clear, turbulence-free water is what I would be looking for.

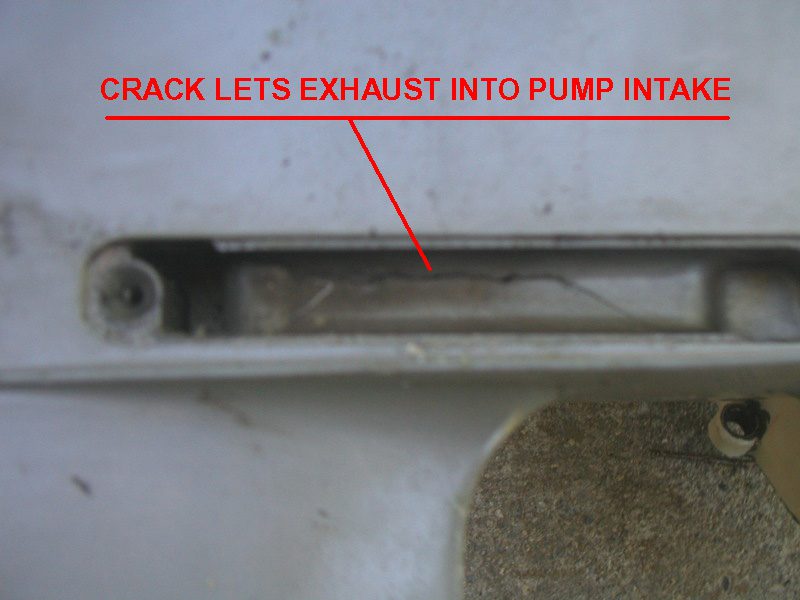

Frank, I am wondering how that crack happened. Was it freeze damage? How the heck did water manage to get trapped so well in there?

Long live American manufacturing!

August 2, 2021 at 8:02 am #244110Thanks again for another good picture Frank….That should be easy enough to spot…. Don’t think it is freeze damage, perhaps just weakness in the casting…I guess this is why the changed the design of this passage and added that extra copper intake pipe in later years….

August 2, 2021 at 9:54 am #244119I run a ’64 RDS-26 (on salt) that has that style of box – the dealers had given up on getting it pumping properly when I bought it from them. Whilst it had a new impeller, no effort had been made to clear out the passages from the pickup tube, nor the channels that appear into the base of the pump ( both were almost completely blocked). The pump housing and area underneath was badly pitted too and looked like it’d chew up impellers over time. It all needed a lot of work before I found a NOS pump housing here. I worked hard with dental picks etc, at clearing everything from the skeg pickup, to the area under the pump, until it was clean. It really does pump properly now, but I can only assume that it was getting a small enough amount to show willing then run out as the water in the pickup passages depleted. Hope the pics help. Have also shown a ’63 Big Twin I had that has a different style of screen.

My spare box is the ’67 version on that dropped the screen & passages and relied on a pickup tube from skeg straight into the back of the pump housing. After ’71 they used a revised pump design with a single pump to powerhead intake design which possibly could be modified (am in the middle of a move with the 71 box buried in the chaos, so I am not sure the bolt pattern is the same..). Am sure there’s better experts than me here, who might be able to advise.

-

This reply was modified 2 years, 9 months ago by

rapier.

August 2, 2021 at 10:09 am #244128Fleetwin,

I knew about the ice damage concerns from a blocked weep hole, but your crack doesn’t seem like a place that could ever trap water. Even if it somehow did I would think it would just stretch the intake plate out before the casting split.

I know you were suggesting a cracked or corroded casting creating a direct path for exhaust into the water pump. I did not find any evidence of that.

With the gearcase leaking badly enough at both the shift O ring and the driveshaft seal, the exhaust path could be literally through the gearcase.Since there is no real harm in doing it, I’ll get the motor put back together and mounted on my boat for a lake test. I’ll change the oil again right before I launch and I wont stay out long.

Rapier,

Wow, crusty. This motor had no blockage in the big water channels and none of the white AL oxide buildup inside. It may be that the salt exposure to this motor was so little that it should not be considered a factor here.-

This reply was modified 2 years, 9 months ago by

jdunham.

August 2, 2021 at 11:13 am #244139Fleetwin,

I knew about the ice damage concerns from a blocked weep hole, but your crack doesn’t seem like a place that could ever trap water. Even if it somehow did I would think it would just stretch the intake plate out before the casting split.

I know you were suggesting a cracked or corroded casting creating a direct path for exhaust into the water pump. I did not find any evidence of that.

With the gearcase leaking badly enough at both the shift O ring and the driveshaft seal, the exhaust path could be literally through the gearcase.Since there is no real harm in doing it, I’ll get the motor put back together and mounted on my boat for a lake test. I’ll change the oil again right before I launch and I wont stay out long.

Rapier,

Wow, crusty. This motor had no blockage in the big water channels and none of the white AL oxide buildup inside. It may be that the salt exposure to this motor was so little that it should not be considered a factor here.-

This reply was modified 2 years, 9 months ago by

jdunham.

Agree…The crack shown in frank’s picture is not from freeze damage….I’m pretty sure it is just common weakness in that casting, which is why it was changed slightly in the later 60s. I suppose anything is possible, is there evidence of gear lube in the impeller housing cavity?

You mentioned you don’t see any cracks/erosion in that intake path, so perhaps it is best to return to “square one” now…Reassemble, put the engine on a boat in the water and try it….August 5, 2021 at 12:54 am #244277If it help, I hit a submerged log once with my 1963 40hp Evinrude Big Twin, which resulted in a crack as shown in Franks photo with the red wording.

The only difference in my case ,was that the crack extended to the gear box, resulting in an oil leak.Might be worth hooking up an electric drill to the drive shaft to see how well the pump works.

Monte NZ

August 5, 2021 at 7:53 am #244287If it help, I hit a submerged log once with my 1963 40hp Evinrude Big Twin, which resulted in a crack as shown in Franks photo with the red wording.

The only difference in my case ,was that the crack extended to the gear box, resulting in an oil leak.Might be worth hooking up an electric drill to the drive shaft to see how well the pump works.

Monte NZ

Good point Monte….But, we have to keep in mind that this test won’t duplicate any exhaust leaks….

But, if the pump doesn’t perform at all during this test, then that certainly indicates an issue….The only tricky part is the two tube system….I guess I would install one of the water tubes in the outlet water pump grommet and keep the return grommet under water while testing….. -

This reply was modified 2 years, 9 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.